Photovoltaic systems

9.1 Components of a PV system The solar energy conversion into electricity takes place in a semiconductor device that is called a solar cell. A solar cell is a unit that delivers only a certain

Get a quote

Types of Electric Cell

Electric cell is the basic component of the electronics industry and is used everywhere as a power supply. Batteries that are used for large voltage supply are also made

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get a quote

Components of a Photovoltaic System

There are three types of solar panels that are widely available for use in photovoltaic systems, (1) monocrystalline, (2) polycrystalline, and (3)

Get a quote

A Comprehensive Guide to the Different Types of

Monocrystalline solar cells are made from single silicon crystals and offer excellent efficiency levels. Polycrystalline solar cells are made from multiple

Get a quote

What are photovoltaic cells?: types and applications

The photovoltaic cell (also known as a photoelectric cell) is a device that converts sunlight into electricity through the photovoltaic effect, a phenomenon discovered in 1839 by

Get a quote

What Are Solar Panels Made Of?

Discover the essential components of solar panels, including photovoltaic cells, glass, and frames. Learn how Rayzon Solar manufactures high-quality solar

Get a quote

photovoltaic Flashcards | Quizlet

Photons striking a solar cell must have energies above a certain minimum energy level to create the photovoltaic effect. Higher energy photons are associated with which of the following?

Get a quote

Solar Photovoltaic Cell Basics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main types of thin-film PV

Get a quote

Photovoltaic Types of PV Cells that Make Solar Panels

There are different photovoltaic types of cells available to buy, but mainly they are manufactured from silicon (Si), the second most abundant element in the Earth''s crust (after oxygen), and

Get a quote

Photovoltaic Cell

Semiconductor Material: Photovoltaic cells are typically made from silicon, a semiconductor material that has the ability to absorb photons of sunlight and release

Get a quote

Solar Cell | Photovoltaic Cell

Most solar photovoltaic cells are composed of silicon, which is used in over 95% of solar cells worldwide because it''s abundant, effective, and easily processed into cells.

Get a quote

Third-generation photovoltaic cell

Third-generation photovoltaic cells are solar cells that are potentially able to overcome the Shockley–Queisser limit of 31–41% power efficiency for single bandgap solar cells. This

Get a quote

Solar Cells: Definition, History, Types & Function | Soly

Learn everything about solar cells: their definition, history, structure, and types. Discover how they work to produce clean energy with Soly''s expert guide.

Get a quote

A Comprehensive Guide for Solar Panel Parts and Functions

Solar panels are composed of twelve essential components that play a crucial role in converting sunlight into clean electricity. At the core of a solar panel, solar cells convert

Get a quote

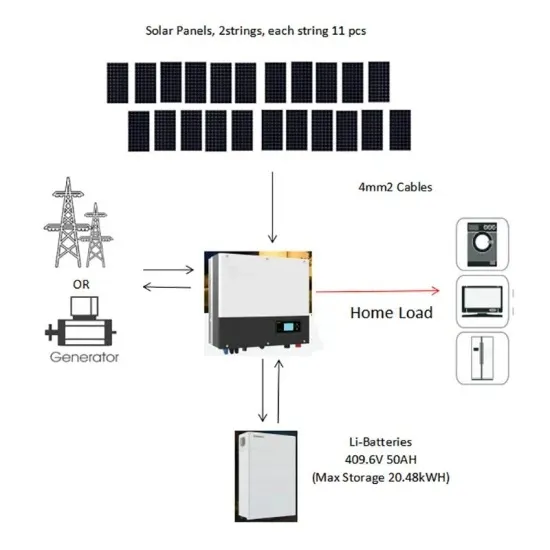

Solar System Components Explained: From Panels to

The key components of a solar system include solar panels, an inverter, and solar batteries. Choosing and setting up a solar system in your

Get a quote

Photovoltaic Cell: Principles, Mechanisms, Applications, and

This article aims to provide an exhaustive overview of photovoltaic cells, detailing their definition, working principles, components, types, applications, advantages, and

Get a quote

Solar Photovoltaic (PV) Cells, Types, Key Components and

Cell Construction: A typical silicon PV cell contains p-type and n-type semiconductor layers forming a p-n junction, which produces an electric potential when illuminated.

Get a quote

What are thin-film solar cells? Types and description

Solar cell material optimization In addition to minimizing the reflective loss, the solar cell material can be optimized to have a greater chance of absorbing a photon that

Get a quote

A Comprehensive Guide to the Different Types of Solar Cells

Monocrystalline solar cells are made from single silicon crystals and offer excellent efficiency levels. Polycrystalline solar cells are made from multiple smaller crystals and tend to be more

Get a quote

Components of a Photovoltaic System

There are three types of solar panels that are widely available for use in photovoltaic systems, (1) monocrystalline, (2) polycrystalline, and (3) amorphous thin-film.

Get a quote

Photovoltaic Types of PV Cells that Make Solar Panels

There are different photovoltaic types of cells available to buy, but mainly they are manufactured from silicon (Si), the second most abundant element in the

Get a quote

Photovoltaic (PV) Cell Types

Photovoltaic cells are made from a variety of semiconductor materials that vary in performance and cost. Basically, there are three main categories of conventional solar cells:

Get a quote

Solar Photovoltaic Cell Basics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main

Get a quote

Guess what you want to know

-

Grid-connected photovoltaic cell components

Grid-connected photovoltaic cell components

-

Portugal non-standard BIPV solar panel components photovoltaic cells

Portugal non-standard BIPV solar panel components photovoltaic cells

-

New photovoltaic cell components

New photovoltaic cell components

-

Photovoltaic cells and components applications

Photovoltaic cells and components applications

-

Which company is best for energy storage photovoltaic projects in the Marshall Islands

Which company is best for energy storage photovoltaic projects in the Marshall Islands

-

Photovoltaic cell module factory in Kenya

Photovoltaic cell module factory in Kenya

-

Swedish photovoltaic cell panels

Swedish photovoltaic cell panels

-

Photovoltaic solar frame components

Photovoltaic solar frame components

-

Photovoltaic cell modules in southern Niger

Photovoltaic cell modules in southern Niger

-

Which manufacturer s photovoltaic panels are good

Which manufacturer s photovoltaic panels are good

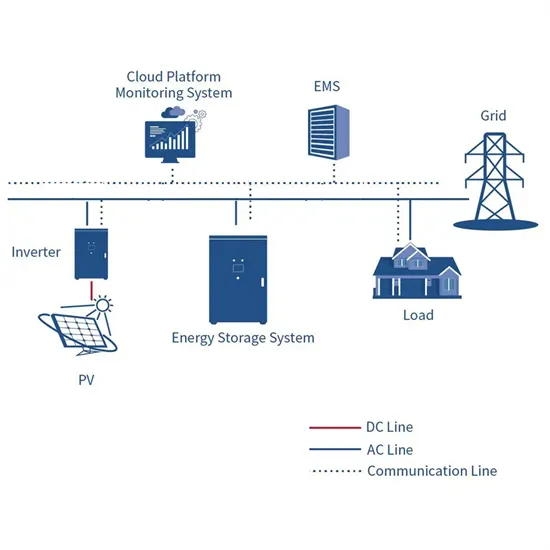

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.