Base station lead-acid energy storage

Telecom Base Station Lithium Battery Electric Energy Storage Communication Transportation Power Data Security Lithium Battery Built for extreme temperature operation up to 50% in

Get a quote

Lead batteries for utility energy storage: A review

Lead–acid batteries are supplied by a large, well-established, worldwide supplier base and have the largest market share for rechargeable batteries both in terms of sales value

Get a quote

AKARI 4V 4.5Ah Sealed Lead Acid Battery – Ideal Power Backup

Get uninterrupted power with the AKARI 4V 4.5Ah Sealed Lead Acid Battery—perfect for Digitone® weighing machines and more. Compact, rechargeable, spill-proof, and ISO-certified

Get a quote

Lead-Acid vs. Lithium-Ion Batteries for Telecom Base

Two primary battery technologies dominate the telecom backup power industry: lead-acid and lithium-ion. Each has its advantages and trade

Get a quote

Lead Acid Battery Weight: How Much Does a Lead Acid Battery Weigh

A standard car lead acid battery weighs between 30 to 50 pounds (14 to 23 kilograms). In contrast, lithium-ion batteries, often used in smartphones and electric vehicles,

Get a quote

Size And Weight Of 12v Car Batteries (With Examples)

What is a 12-volt battery? The 12-volt lead-acid battery is the industry standard used in most automobiles today. Its purpose is for starting

Get a quote

Lead-Acid Batteries Examples and Uses

Lead-acid batteries are one of the most widely used rechargeable battery types, known for their reliability, affordability, and high energy output. They power everything from

Get a quote

Use of Batteries in the Telecommunications Industry

Large telecom offices and cell sites with dedicated generators have 3 to 4 hours of battery reserve time A large telecom office may have over 400 cells and 8000 gallons of electrolyte

Get a quote

Weight standard of lead-acid batteries in computer rooms

Abstract: Vented lead-acid (VLA), valve-regulated lead-acid (VRLA), and nickel-cadmium (NiCd) stationary battery installations are discussed in this guide, written

Get a quote

SECTION 6: BATTERY BANK SIZING PROCEDURES

Smallest cell capacity available for selected cell type that satisfies capacity requirement, line 6m, when discharged to per-cell EoD voltage, line 9d or 9e, at functional hour rate, line 7. OR, if no

Get a quote

What Is a Forklift Battery Weight Chart and Why Does

A forklift battery weight chart provides weight ranges for different battery types (lead-acid, lithium-ion) based on voltage and capacity. For

Get a quote

Battery Sizing Considerations IEEE 2020

NiCad batteries typically operate between 1.00vpc and up to 1.65vpc depending on load voltage tolerance. 125Vdc: 105Vdct to 140Vdc *Should be based on equipment connected to the

Get a quote

Lead-acid Battery for Telecom Base Station Market

Quick Q&A Table of Contents Infograph Methodology Customized Research Key Demand Drivers for Lead-Acid Batteries in Telecom Base Stations The telecom base station sector relies on

Get a quote

Base Station Batteries

REVOV''s lithium iron phosphate (LiFePO4) batteries are ideal telecom base station batteries. These batteries offer reliable, cost-effective backup power for communication networks. They

Get a quote

DOE-HDBK-1084-95; Primer on Lead-Acid Storage Batteries

Sizing and selection of lead-acid batteries should be performed according to ANSI/IEEE Std 485, IEEE Recommended Practice for Sizing Large Lead Storage Batteries for Generating Stations

Get a quote

IEEE IAS Stationary Battery Sizing 4-20-15

It is prudent to provide a capacity margin to the battery sizing for unforeseen additions to the dc system and less than optimum operating conditions. Typical design

Get a quote

Battery Discharge Testing: Implementing NERC Standards

With the approval of NERC PRC 005-2 "Protection System Maintenance" standard, entities falling under its umbrella will have to test batteries per its requirements. The paper focus on

Get a quote

Lead-acid battery capacity standards and weight

Energy Density or Specific Energy: Lithium-ion batteries have a higher energy density or specific energy, meaning they can store more energy per unit volume or weight than lead-acid batteries.

Get a quote

PS-HTR-ST-49-E_Sealed Lead Acid Battery OPTIMA

The following information is provided for battery electrolyte (acid) and lead for exposures that may occur during battery production or container breakage or under extreme heat conditions such

Get a quote

Lead Acid Battery Weight: How Much Does a Lead Acid Battery

A standard car lead acid battery weighs between 30 to 50 pounds (14 to 23 kilograms). In contrast, lithium-ion batteries, often used in smartphones and electric vehicles,

Get a quote

IS 1652 (1991): Stationary cells and batteries,lead-acid type

dimensions, capacities andperformance requirements of stationary cells and batteries of lead-acid type with plante positive plates. Forpreparation of this standard, ssistance w sd rived from BS

Get a quote

How many tons of energy storage batteries are used in base stations

To apply an accurate energy storage metric, one should delve into the average capacity of batteries deployed in these installations. Roughly, these batteries range from 5

Get a quote

How many tons of energy storage batteries are used

To apply an accurate energy storage metric, one should delve into the average capacity of batteries deployed in these installations. Roughly,

Get a quote

Comparison of LiFePO4 battery and lead-acid battery in base station

Explore the critical considerations in selecting batteries for base stations. This comparison between LiFePO4 and lead-acid batteries delves into power consumption, backup time, and

Get a quote

Comparison of LiFePO4 battery and lead-acid battery in base

Explore the critical considerations in selecting batteries for base stations. This comparison between LiFePO4 and lead-acid batteries delves into power consumption, backup time, and

Get a quote

6 FAQs about [Base station lead-acid battery weight standard]

How much does a lead acid battery weigh?

Lead acid batteries typically weigh more than many other common battery types. A standard car lead acid battery weighs between 30 to 50 pounds (14 to 23 kilograms). In contrast, lithium-ion batteries, often used in smartphones and electric vehicles, weigh significantly less.

Are lead acid batteries portable?

Portability challenges arise from the substantial weight of lead acid batteries. Lead acid batteries generally weigh between 30 to 70 pounds (13.6 to 31.8 kg). This weight makes them less convenient for applications requiring frequent transport, like portable devices.

Why are lead acid batteries important in energy storage technology?

This information underlines their significance in energy storage technology. The heavy nature of lead acid batteries can affect transportation costs and energy efficiency in vehicles, potentially increasing environmental impact. Health risks exist due to the lead and sulfuric acid content in these batteries.

How much do AGM batteries weigh?

AGM (Absorbent Glass Mat) batteries weigh differently compared to traditional lead-acid batteries. AGM batteries typically weigh less due to their design and materials. For example, a standard 12V AGM battery can weigh around 30-50 pounds, while a comparable lead-acid battery may weigh 40-60 pounds.

Are lead acid batteries bad for the environment?

The heavy nature of lead acid batteries can affect transportation costs and energy efficiency in vehicles, potentially increasing environmental impact. Health risks exist due to the lead and sulfuric acid content in these batteries. Improper disposal can harm the environment and human health.

What is a good capacity margin for a Battery sizing?

It is prudent to provide a capacity margin to the battery sizing for unforeseen additions to the dc system and less than optimum operating conditions. Typical design margins are 10-15%. If cells of sufficiently large capacity are not available, then two or more strings may be connected in parallel.

Guess what you want to know

-

Belgian communication base station lead-acid battery bidding

Belgian communication base station lead-acid battery bidding

-

Kuwait Da Communication Base Station Lead-acid Battery

Kuwait Da Communication Base Station Lead-acid Battery

-

Third-party communication base station lead-acid battery equipment

Third-party communication base station lead-acid battery equipment

-

Kuwait Solar Base Station Lead-Acid Battery 418KWh

Kuwait Solar Base Station Lead-Acid Battery 418KWh

-

What s inside a lead-acid battery in a communication base station

What s inside a lead-acid battery in a communication base station

-

Somalia communication base station lead-acid battery cabinet in stock

Somalia communication base station lead-acid battery cabinet in stock

-

Comoros emergency communication base station lead-acid battery

Comoros emergency communication base station lead-acid battery

-

New energy storage communication base station lead-acid battery

New energy storage communication base station lead-acid battery

-

Base station lead-acid battery charging

Base station lead-acid battery charging

-

Morocco communication base station lead-acid battery bidding

Morocco communication base station lead-acid battery bidding

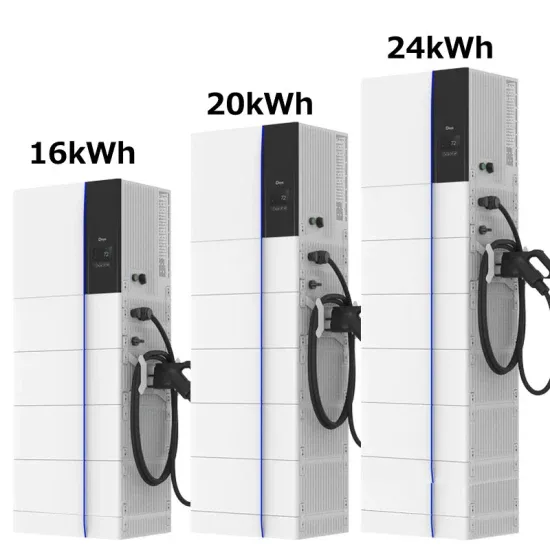

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.