Vanadium Redox-Flow Battery

As the schematic shown in Fig. 1, a vanadium redox-flow battery has two chambers, a positive chamber and a negative chamber, separated by an ion-exchange membrane.

Get a quote

Vanadium redox reactions and carbon electrodes for vanadium redox flow

The redox reactions of vanadium ions in sulfuric,acid, which are used for anolyte and catholyte in a redox flow battery, have been investigated on a

Get a quote

Dynamic modeling of vanadium redox flow batteries: Practical

These features follow from the structure and operation of such batteries. A redox flow battery consists of two tanks filled with two electrolytes containing different active redox

Get a quote

Vanadium Redox Flow Batteries: A Review Oriented

Large-scale energy storage systems (ESS) are nowadays growing in popularity due to the increase in the energy production by renewable

Get a quote

VRB Batteries vs Lithium-Ion: Key Differences Explained

Among the many battery technologies available today, Vanadium Redox Flow Batteries (VRB) and Lithium-Ion Batteries stand out as two of the

Get a quote

Sustainable recycling and regeneration of redox flow battery

As the demand for large-scale sustainable energy storage grows, redox flow batteries (RFBs), particularly all-vanadium RFBs (VRFBs), have emerged as a promising

Get a quote

SECTION 5: FLOW BATTERIES

Redox reactions occur in each half-cell to produce or consume electrons during charge/discharge. Similar to fuel cells, but two main differences: Reacting substances are all in the liquid phase.

Get a quote

Vanadium flow batteries at variable flow rates

A laboratory-scale single cell vanadium redox flow battery (VRFB) was constructed with an active area of 64 cm 2. The electrolyte was produced by dissolving vanadium

Get a quote

A technology review of electrodes and reaction mechanisms in vanadium

This work reviews and discusses the progress on electrodes and their reaction mechanisms as key components of the vanadium redox flow battery over the past 30 years.

Get a quote

Vanadium redox flow batteries: A comprehensive review

There are currently a limited number of papers published addressing the design considerations of the VRFB, the limitations of each component and what has been/is being

Get a quote

State-of-art of Flow Batteries: A Brief Overview

The commercialized flow battery system Zn/Br falls under the liquid/gas-metal electrode pair category whereas All-Vanadium Redox Flow Battery (VRFB)

Get a quote

A general electrochemical formalism for vanadium redox flow

Recent advancements in Vanadium Redox Flow Batteries (VRFBs) assert that their performance degradation and lack of charge retention is generally ascribed to the

Get a quote

Dynamic modelling of the effects of ion diffusion and side reactions

The diffusion of vanadium ions across the membrane along with side reactions can have a significant impact on the capacity of the vanadium redox flow battery (VFB) over long

Get a quote

A comprehensive study of parasitic gas evolution reactions in a

The gas evolution reactions (GERs) in a vanadium redox flow battery (VRFB) are dangerous and can cause a series of issues such as an imbalance in the state of charge

Get a quote

Vanadium Redox Flow Battery

Vanadium redox flow batteries also known simply as Vanadium Redox Batteries (VRB) are secondary (i.e. rechargeable) batteries. VRB are applicable at grid scale and local user level.

Get a quote

Understanding the Vanadium Redox Flow Batteries

s transfer. VRB differ from conventional batteries in two ways: 1) the reaction occurs between two electrolytes, rather than between an electrolyte and an electrode, therefore no electro

Get a quote

Investigating the V(II)/V(III) electrode reaction in a vanadium

We investigated the reaction and processes in the negative VRFB half-cell using electrochemical impedance spectroscopy combined with the distribution of relaxation times

Get a quote

Thermal modelling of battery configuration and self-discharge reactions

During the operation of vanadium redox flow battery, the vanadium ions diffuse across the membrane as a result of concentration gradients between the two half-cells in the

Get a quote

Vanadium redox battery

One of the important breakthroughs achieved by Skyllas-Kazacos and coworkers was the development of a number of processes to produce vanadium electrolytes of over 1.5 M

Get a quote

Evaluation of the effect of hydrogen evolution reaction on the

The exceptional advantages of vanadium redox flow batteries (VRFBs) have garnered significant attention, establishing them as the preferred choice for large-scale and

Get a quote

How Vanadium Flow Batteries Work

Invinity''s products employ time-proven, globally-deployed Vanadium Flow Battery (or "VFB") technology to deliver safe, reliable, economical energy storage.

Get a quote

Vanadium Redox Battery – Zhang''s Research Group

Flow batteries always use two different chemical components into two tanks providing reduction-oxidation reaction to generate flow of electrical current.

Get a quote

A technology review of electrodes and reaction

This work reviews and discusses the progress on electrodes and their reaction mechanisms as key components of the vanadium redox flow battery over the

Get a quote

Vanadium Redox Flow Battery: Review and Perspective of 3D

By employing a flexible electrode design and compositional functionalization, high-speed mass transfer channels and abundant active sites for vanadium redox reactions can be

Get a quote

Guess what you want to know

-

Vanadium redox flow battery equipment manufacturing

Vanadium redox flow battery equipment manufacturing

-

Smart vanadium flow battery

Smart vanadium flow battery

-

Vanadium flow battery configuration

Vanadium flow battery configuration

-

Paraguayan vanadium redox flow battery

Paraguayan vanadium redox flow battery

-

Vanadium titanium all-vanadium liquid flow energy storage battery

Vanadium titanium all-vanadium liquid flow energy storage battery

-

Yaounde Vanadium Flow Battery Company

Yaounde Vanadium Flow Battery Company

-

Vanadium flow battery in western Denmark mining

Vanadium flow battery in western Denmark mining

-

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

-

Vanadium flow battery energy storage trends

Vanadium flow battery energy storage trends

-

Albania Vanadium Flow Battery Energy Storage Station

Albania Vanadium Flow Battery Energy Storage Station

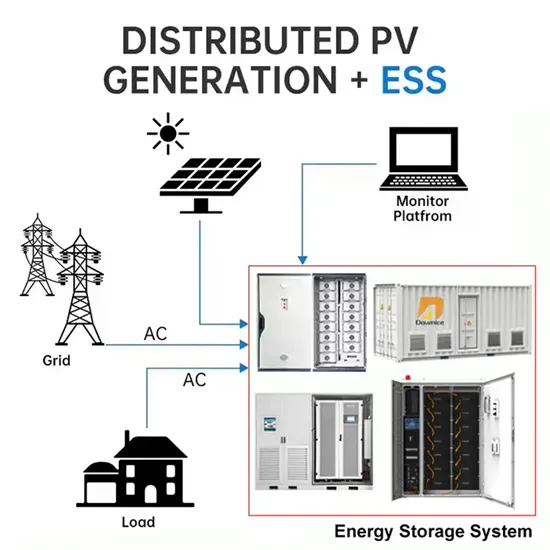

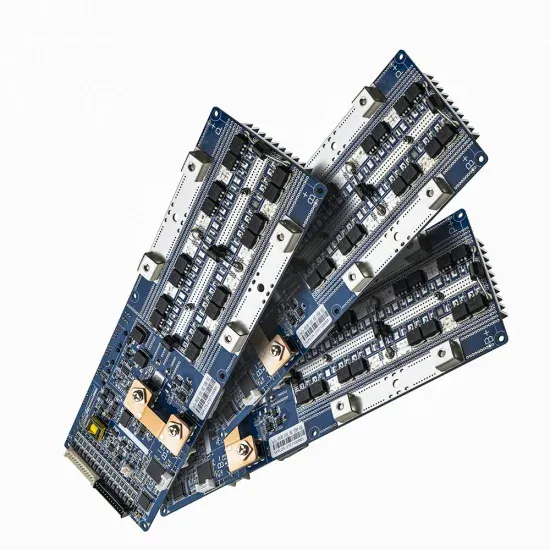

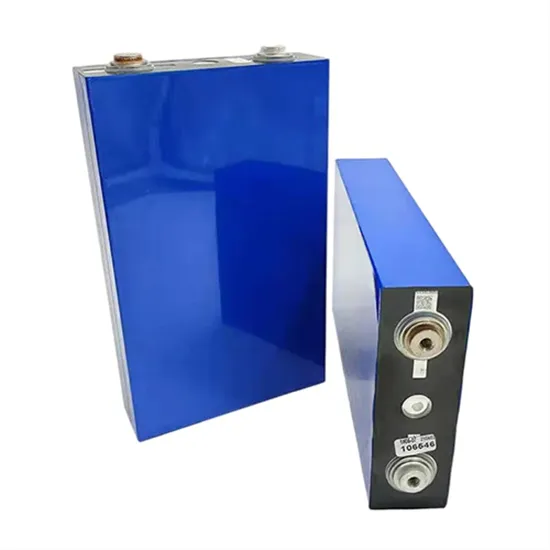

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

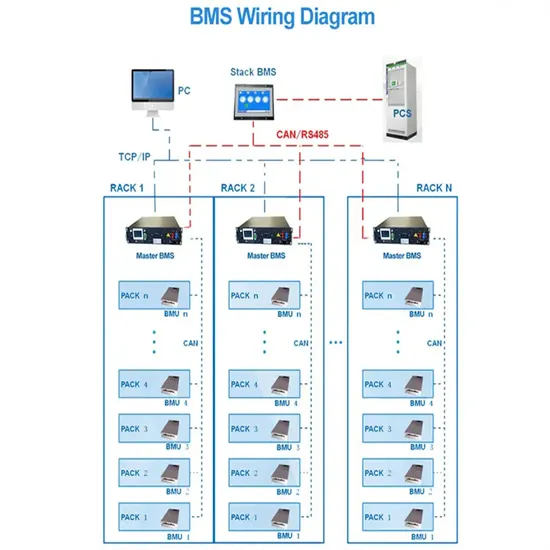

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.