Key Points of Lithium Battery PACK Manufacturing Process

Curious about how lithium batterypacks are made? Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to

Get a quote

What Is the Process of Lithium-Ion Battery Pack Assembly

As a vital element in the lithium ion battery manufacture process, the pack plays a pivotal role in the production, design, and application of power battery systems.

Get a quote

Key Points of Lithium Battery PACK Manufacturing

Curious about how lithium batterypacks are made? Dive into the detailed process behind these essential energy storage solutions! From

Get a quote

Lithium-Ion Battery Pack Processing Line: Process Flow and

Process Flow of Lithium-Ion Battery Pack Processing Line Sorting and Grouping Process Objective: Select cells with consistent parameters (voltage, internal resistance, capacity) to

Get a quote

Shredding the Largest EV Battery Packs in One System

Innovative technology allows for safe, efficient, profitable shredding of the largest EV battery packs on the market, without disassembly or

Get a quote

Advanced electrode processing for lithium-ion battery

This Review discusses the benefits and drawbacks of advanced electrode processing methods, including aqueous, dry, radiation curing and 3D-printing processing

Get a quote

Lithium Battery Packs Manufacturer | High-Quality

Shenzhen Deriy New Energy Technology Co., Ltd. provides high-quality lithium battery packs for diverse industries. Our aging tests ensure long service life

Get a quote

"It''s the start of something big"

From 2025, MAN will manufacture its own battery packs in a mass production facility in Nuremberg. The foundation stone for this key future project was laid on 10 October.

Get a quote

What Is the Process of Lithium-Ion Battery Pack

As a vital element in the lithium ion battery manufacture process, the pack plays a pivotal role in the production, design, and application of

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

Lithium-ion Battery Manufacturing Front to End | by Dominic Tsoi

There are 3 main stages in Li-ion cell production. There are subprocesses within the 3 main stages and are mostly similar across different cell formats (prismatic, cylindrical and

Get a quote

Direct recycling of Li-ion batteries from cell to pack

Direct recycling is a novel approach to overcoming the drawbacks of conventional lithium-ion battery (LIB) recycling processes and has gained considerable

Get a quote

Dominic shares lithium battery diaphragm equipment

What is the production capacity of lithium-ion battery diaphragm? Among them, the production capacity of dry-process lithium-ion battery diaphragm design is 100 million square meters, and

Get a quote

Dominic with lithium-ion battery

Secondary Lithium-Ion Battery Anodes: From First Addressing the challenges in rechargeable lithium-ion battery technologies By Nicholas Loeffl er, Dominic Bresser and Stefano

Get a quote

Lithium-Ion Battery Manufacturing: Industrial View on Processing

Then, battery modules with electrical, thermal and mechanical components are assembled into a battery pack. It should be noted that in this paper, either battery or the cell

Get a quote

Dominic lithium battery pack processing

What is a lithium battery pack manufacturing process? The production of lithium battery modules, also known as Battery Packs, involves a meticulous and multi-step manufacturing process.

Get a quote

Lithium-ion batteries – Current state of the art and anticipated

An increased volume of battery production will notably affect the environment due to raw material processing and generation of secondary streams [378]. Currently in the

Get a quote

Lithium Processing

Lithium Refining: Spodumene concentrate to battery grade Li2CO3 The spodumene concentrate ore is converted into Lithium Carbonate for use as an essential component to make Lithium

Get a quote

Battery Pack Processing in Türkiye

Lithium-ion Battery Pack Manufacturing Process & Design At the heart of the battery industry lies an essential lithium ion battery assembly process called battery pack production. In this article,

Get a quote

From Raw Materials to Finished Product: The Lithium Batteries

In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge advancement in modern manufacturing

Get a quote

What are the critical processes for lithium battery pack processing?

One category accounts for about 30% of the value of lithium battery pack processing lines. Lithium battery back-end process: the core part of the lithium battery pack''s back-end processing

Get a quote

Lithium-ion cell and battery production processes

In contrast to module and pack assembly, the production of lithium-ion battery cells typically integrates various production technologies and draws on wide-ranging fields of

Get a quote

The present invention relates to a batch processing system for waste lithium secondary batteries, which disassembles and batch-processes waste lithium secondary batteries of a pack state

Get a quote

From Raw Materials to Finished Product: The Lithium

In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Get a quote

MAN Truck & Bus Advances Battery Production with New Facility

Using robot-guided optics and precise sensors, this process ensures high-quality connections for individual battery cells. MAN is collaborating with the Technical University of

Get a quote

Guess what you want to know

-

Peru low temperature lithium battery pack processing

Peru low temperature lithium battery pack processing

-

Middle East pack lithium battery processing

Middle East pack lithium battery processing

-

Philippines lithium battery pack processing and wholesale

Philippines lithium battery pack processing and wholesale

-

Mongolia lithium battery pack processing

Mongolia lithium battery pack processing

-

South America graphene lithium battery pack

South America graphene lithium battery pack

-

What is the volume of a 24v 12A lithium battery pack

What is the volume of a 24v 12A lithium battery pack

-

Lithium iron phosphate battery pack requires balanced voltage

Lithium iron phosphate battery pack requires balanced voltage

-

Lithium battery pack capacity decreases

Lithium battery pack capacity decreases

-

How much does a 380v three-phase lithium battery pack cost

How much does a 380v three-phase lithium battery pack cost

-

Special-shaped lithium battery pack

Special-shaped lithium battery pack

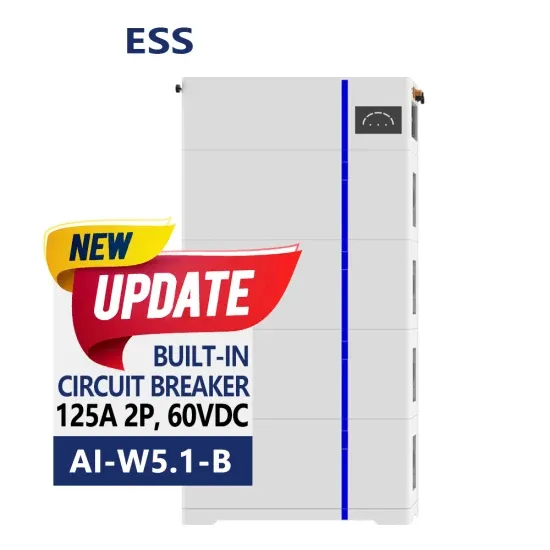

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.