Mapping the future of solar capacity in Southeast Asia

It is Southeast Asia''s largest and the world''s third-largest floating solar plant, a collaboration between Indonesia''s state-owned PLN and Abu

Get a quote

Renewable Energy Manufacturing in Southeast Asia Can

The new report, Renewable Energy Manufacturing: Opportunities for Southeast Asia, explores how to support the development of the clean energy manufacturing sector in

Get a quote

Mapping the future of solar capacity in Southeast Asia

It is Southeast Asia''s largest and the world''s third-largest floating solar plant, a collaboration between Indonesia''s state-owned PLN and Abu Dhabi-based Masdar.

Get a quote

Why Southeast Asia is the Next Global Factory

Southeast Asia isn''t just an alternative—it''s the future of global manufacturing. With Vietnam leading in electronics, Indonesia shaping the EV industry, Thailand pioneering

Get a quote

Sinovoltaics Southeast Asia SEA Solar Energy Supply Chain Map

This edition of the Southeast Asia Solar Supply Chain Map provides a detailed snapshot of current realities and future ambitions, as the region navigates complex trade, investment, and

Get a quote

$6.5 Million Investment: Leading PV Company Plans to Build

It will be responsible for the localized production, sales, and technical services of PV module and cell equipment, directly serving emerging markets such as Southeast Asia and the

Get a quote

Haijuxing Indonesia 3GW Photovoltaic Manufacturing Base May

On March 28th, Chinese photovoltaic company Haijuxing announced the official shipment of the first batch of 120 single crystal growth furnaces from its Indonesian production

Get a quote

2.1GWh! Two Companies Sign Major Energy Storage Deals,

2GWh Equipment + 1GWh Plant! Gansu Qingyang Partners with Tongli Risheng and Tianqi Hongyuan On March 5, Qingyang Municipal Government signed a strategic

Get a quote

Construction works commences for the first 1 GW solar PV

CGN has launched the construction of Laos'' first large-scale solar photovoltaic (PV) project. The project, part of the Northern Laos Interconnected Clean Energy Base, aims

Get a quote

Untapped Potential: Scaling solar PV and battery manufacturing

To foster growth in the battery industry in Southeast Asia, it is particularly important to target global export markets given the domestic market is growing from a smaller base.

Get a quote

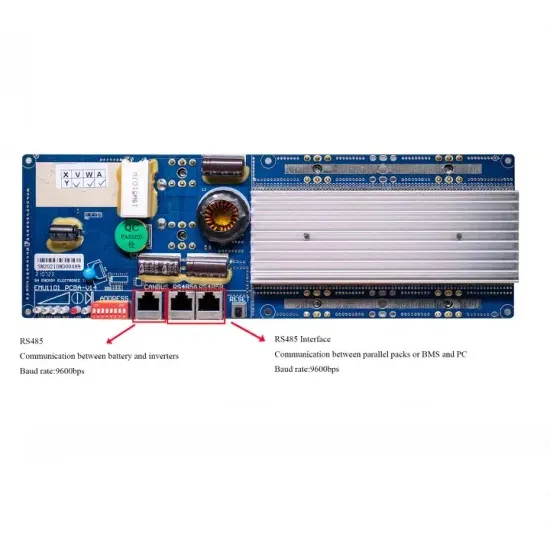

Solar telecommunications base station

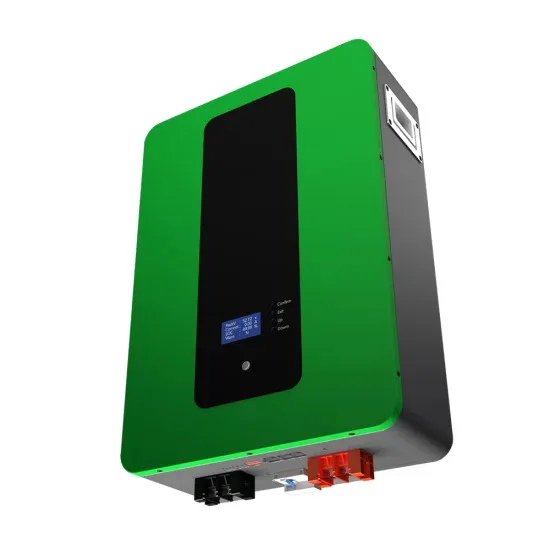

Power generation equipment includes diesel generators, photovoltaic arrays, wind turbines or hydroelectric generators. Energy storage equipment usually has a battery pack or energy

Get a quote

Solar telecommunications base station

Power generation equipment includes diesel generators, photovoltaic arrays, wind turbines or hydroelectric generators. Energy storage equipment usually has a

Get a quote

$6.5 Million Investment: Leading PV Company Plans to Build Overseas Factory

It will be responsible for the localized production, sales, and technical services of PV module and cell equipment, directly serving emerging markets such as Southeast Asia and the

Get a quote

Mapping the future of solar capacity in Southeast Asia

Inside a solar cell factory in east China''s Jiangsu province. Chinese companies make most of the solar panels used in Southeast Asia, though Thailand has emerged as a

Get a quote

Final U.S. Tariffs on Solar Imports from Southeast Asia (2025

Discover how new 2025 U.S. tariffs on solar panels from Malaysia, Thailand, Vietnam, and Cambodia could impact importers and developers. Learn strategies to reduce

Get a quote

Renewable Energy Manufacturing: Opportunities for Southeast Asia

This report explains how Southeast Asia can become a leader in renewable energy manufacturing and the benefits this will bring by boosting jobs, improving energy security, and helping the

Get a quote

LONGi faces questions over Southeast Asian factories

Chinese solar manufacturing giant LONGi has addressed rumours it is planning to shut down production at its facilities in Southeast Asia.

Get a quote

Renewable Energy Manufacturing: Opportunities for

This report explains how Southeast Asia can become a leader in renewable energy manufacturing and the benefits this will bring by boosting jobs,

Get a quote

CEEC Signs EPC Project for Southeast Asia S Largest Integrated

The EPC project will cover the design, procurement, construction, commissioning and other links of photovoltaic power stations and electrochemical energy storage power

Get a quote

Leaving Southeast Asia, where should Chinese photovoltaic

Chinese photovoltaic enterprises have successively "gone to Southeast Asia", and the leading enterprises have integrated production capacity from silicon wafers to modules.

Get a quote

SEG Solar and Grand Batang City Sign Land Utilization

The park is anticipated to include factories for the production and assembly of silicon ingots, wafers, cells, and modules and is set to become Southeast Asia''s largest

Get a quote

5G Base Station Solar Photovoltaic Energy Storage Integration

By installing solar photovoltaic panels at the base station, the solution converts solar energy into electricity, and then utilizes the energy storage system to store and manage

Get a quote

Longi denies rumors about factory closures in

The company claimed that it will "appropriately adjust production arrangements based on market changes and the progress of its equipment

Get a quote

Untapped Potential: Solar PV and battery manufacturing

Southeast Asia has significant potential to establish an end-to-end battery value chain, given its rich critical mineral resources and strong interest from global industry players

Get a quote

An Overview of Global Electronics Industry in

Southeast Asian countries are becoming one of the beneficiary regions of the semiconductor industry migration. From IC design, testing, packaging to

Get a quote

6 FAQs about [Southeast Asia Communications Photovoltaic Base Station Equipment Processing Factory]

What is the Southeast Asia Solar supply chain map?

This edition of the Southeast Asia Solar Supply Chain Map provides a detailed snapshot of current realities and future ambitions, as the region navigates complex trade, investment, and production challenges.

Is Southeast Asia an exporter of solar PV products?

Southeast Asia is largely an exporter of solar PV products today. Its nameplate capacity of 70 GW dwarfs regional demand of ~3 GW p.a. There are three broad archetypes of producer countries in the region:

Who makes solar panels in Southeast Asia?

According to manufacturers’ present in Southeast Asia today, most manufacturing capacity in the region was established by manufacturers from the People’s Republic of China. Southeast Asia is largely an exporter of solar PV products today.

What is China energy construction in Southeast Asia?

As another masterpiece of China Energy Construction in Southeast Asia, the Terra PV storage project will make full use of the abundant local solar energy resources to provide a stable power supply of no less than 84 hours a week and 600 MW through the joint operation of photovoltaic power plants and energy storage systems.

Why is PV module manufacturing under pressure in Southeast Asia?

Despite strong ambitions, PV module manufacturing in Southeast Asian is currently under pressure. Operational capacities have been significantly reduced or temporarily halted, primarily due to U.S. import tariffs. Once a strategic workaround for Chinese manufacturers aiming to access Western markets, Southeast Asia now faces growing constraints.

How can Southeast Asia become a battery manufacturing hub?

Develop a regional battery manufacturing value chain, increasing national and regional demand, and establish Southeast Asia as a regional and global export hub, producing 140–180 gigawatt-hours (GWh) of battery cells by 2030.

Guess what you want to know

-

Solar thermal equipment for communication base station solar photovoltaic panel factory

Solar thermal equipment for communication base station solar photovoltaic panel factory

-

Burundi Communications Green Base Station Equipment

Burundi Communications Green Base Station Equipment

-

China Mobile base station equipment photovoltaic

China Mobile base station equipment photovoltaic

-

West Asia emergency communication base station power supply equipment

West Asia emergency communication base station power supply equipment

-

Huawei Communications 5G base station equipment

Huawei Communications 5G base station equipment

-

Mobile base station equipment photovoltaic power generation system standard

Mobile base station equipment photovoltaic power generation system standard

-

What are the photovoltaic power generation of base station communication equipment

What are the photovoltaic power generation of base station communication equipment

-

Haiti Communication Photovoltaic Base Station Equipment Customization

Haiti Communication Photovoltaic Base Station Equipment Customization

-

Solar thermal equipment for communication base station solar panel factory

Solar thermal equipment for communication base station solar panel factory

-

Base station power photovoltaic power generation equipment

Base station power photovoltaic power generation equipment

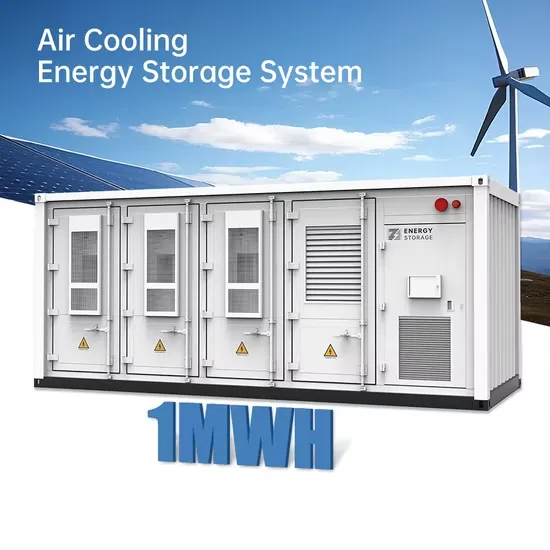

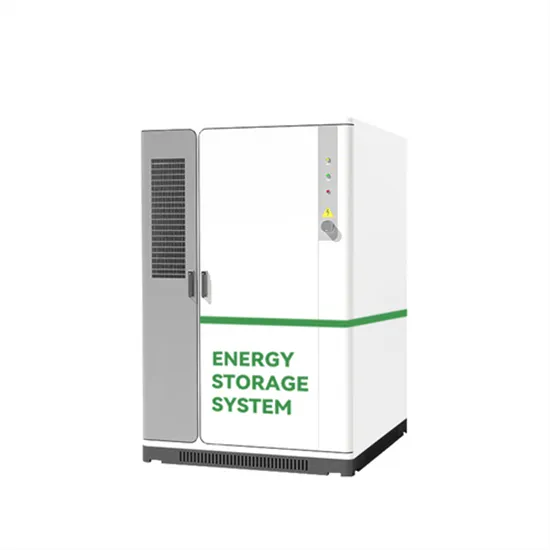

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.