What are the energy storage battery production equipment?

The types of equipment widely employed in battery production include electrode manufacturing machinery, cell assembly lines, testing systems, and waste handling solutions.

Get a quote

Battery Room Ventilation and Safety

This safety factor is to allow for hydrogen production variations with changes in temperature, charge controller failure, and reduction in net volume of battery room due to battery equipment

Get a quote

Battery Production | Lithium-ion & EV Battery Manufacturing

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

Get a quote

Telecom Cabinets

As a leading manufacturer, we deliver IP65-compliant outdoor enclosures and telecom cabinets with excellent protection performance. Our solutions support integration of air conditioning,

Get a quote

Battery Cabinets and Enclosures Manufacture

We''re one of the industry leader in manufacturing of energy storage systems that rank highest in quality, safety, maintenance and ease of use. Openex manufactures first-class battery

Get a quote

Forming Battery cabinet

The formation battery cabinet is the key equipment for battery manufacturing, and the precise control of the battery is realized through the precision manufacturing process. It plays an

Get a quote

2018 Title Contents

Abstract Changes in requirements to meet battery room compliance can be a challenge. Local Authorities Having Jurisdictions often have varying requirements based on areas they serve.

Get a quote

What are the lithium battery production equipment?

According to the production process of lithium-ion batteries, lithium battery equipment can be mainly divided into front-end equipment, mid-end equipment and back-end equipment.

Get a quote

What are the lithium battery production equipment?

According to the production process of lithium-ion batteries, lithium battery equipment can be mainly divided into front-end equipment, mid-end

Get a quote

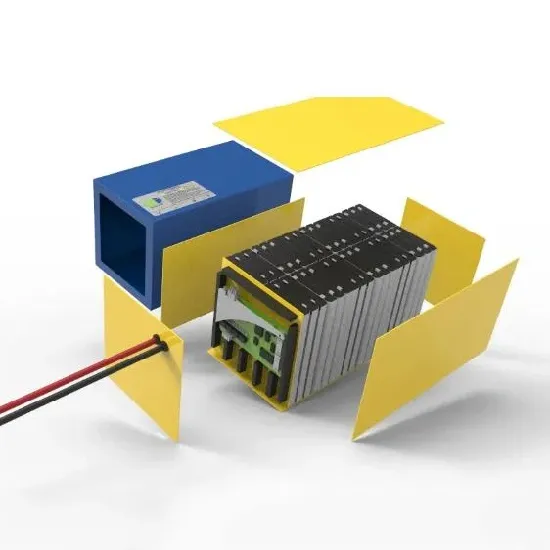

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get a quote

Complete Guide for Battery Enclosure

Battery manufacturing is a sophisticated endeavor requiring a diverse range of specialized machines. From material preparation to cell assembly, testing, and quality control,

Get a quote

Unveiling Prismatic Battery Fabrication Equipment:

Conclusion: Prismatic battery assembly equipment embodies a synergy of precision engineering and advanced automation, contributing to the

Get a quote

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

Get a quote

Exploring the World of Cabinet Type Energy Storage Battery

In the realm of modern energy solutions, cabinet type energy storage battery factories play a crucial role in meeting the growing demands for sustainable power sources.

Get a quote

Battery Storage Cabinets: The Backbone of Safe and Efficient

Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications across industries.

Get a quote

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or cabinet is always a

Get a quote

Lithium-ion Battery Module and Pack Production Line Process Flow

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve

Get a quote

Understanding the Lithium

A lithium - battery aging cabinet, also known as a battery formation and aging system, is a specialized piece of equipment designed to subject newly manufactured lithium -

Get a quote

Brief Introduction To Machines Used In Battery Manufacturing

Battery manufacturing is a sophisticated endeavor requiring a diverse range of specialized machines. From material preparation to cell assembly, testing, and quality control,

Get a quote

Battery Cabinets for Uninterrupted Power Supply (UPS)

Battery Cabinets Through cutting-edge research and innovation, advanced engineered power products for backup battery cabinets have become

Get a quote

Battery Storage Cabinet

KDST provides high-performance battery energy storage cabinet solutions, specially designed for key applications such as telecom base stations, industrial control, and power systems.The

Get a quote

Battery Pack Manufacturing Process: Step-by-Step Guide

Explore how battery cells are connected, modularized, and equipped with BMS in the Battery Pack Manufacturing Process to deliver efficient and reliable energy for multiple

Get a quote

UPS Battery Cabinet Upgrade, Retrofit, Replacement

UPS Battery Upgrade, Retrofit, and Replacement At Mitsubishi Electric, we have the products and expertise to guide you through battery and battery cabinet/rack decisions to promote the life

Get a quote

Battery Storage Cabinets: The Backbone of Safe and

Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications

Get a quote

Battery cabinet production cost accounting

The OmniPower stackable battery cabinets are strong, locally-manufactured powder-coated steel units that ensure your battery bank is safely enclosed while adding great aesthetic appeal to

Get a quote

Battery production process and equipment innovation

The update and iteration of lithium battery equipment and further breakthroughs in lithium battery production technology require close

Get a quote

Guess what you want to know

-

What are the energy battery cabinet equipment on the site

What are the energy battery cabinet equipment on the site

-

What brands of site energy battery cabinet equipment are there

What brands of site energy battery cabinet equipment are there

-

What is the battery cabinet used for communication high voltage cabinet

What is the battery cabinet used for communication high voltage cabinet

-

What are the battery cabinet temperature control systems

What are the battery cabinet temperature control systems

-

What are the battery cabinet factories in Bangladesh

What are the battery cabinet factories in Bangladesh

-

Energy storage cabinet battery equipment cost

Energy storage cabinet battery equipment cost

-

What is the price of Malta outdoor communication battery cabinet

What is the price of Malta outdoor communication battery cabinet

-

What is the appropriate battery capacity for the battery cabinet

What is the appropriate battery capacity for the battery cabinet

-

What is the normal current of a 9v battery in an energy storage cabinet

What is the normal current of a 9v battery in an energy storage cabinet

-

Battery cabinet production and design outdoor site

Battery cabinet production and design outdoor site

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.