High Frequency Inverter Schematic

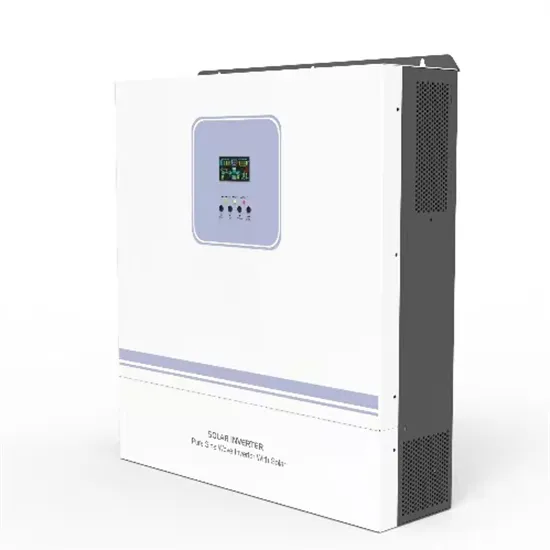

When it comes to high frequency inverters, the main advantage is their ability to operate at higher frequencies than conventional power inverters. This means they can

Get a quote

5kva Ferrite Core Inverter Circuit – Full Working

But since 50 kHz frequency may not be suitable for our home appliances, we need to convert this high frequency AC into the required 50 Hz

Get a quote

1.5kw Frequency Inverter, Single Phase 120V Input,

1.5kw frequency drive inverter, single phase 120v input, single phase and three phase 220v output. 2hp variable frequency drive inverter can drive

Get a quote

DC-to-AC Converters (Inverters): Design, Working & Applications

They are used in power electronic applications where the power input pure 12V, 24V, 48V DC voltage that requires power conversion for an AC output with a certain frequency.

Get a quote

CHAPTER 2

2.2 Voltage Control in Single - Phase Inverters The schematic of inverter system is as shown in Figure 2.1, in which the battery or rectifier provides the dc supply to the inverter. The inverter is

Get a quote

Understanding High-Frequency Inverters

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current

Get a quote

12v DC to 220v AC inverter circuit using TL494 IC

This inverter circuit is suitable for applications requiring high efficiency DC to AC conversion, such as power backup systems or off grid energy solutions. The use of high

Get a quote

Design and Construction of 1KW (1000VA) Power

The purpose of this project is to design and construct a 1000Watts (1KW) 220 Volts Inverter at a frequency of 50Hz. This device is constructed

Get a quote

12v DC to 220v AC inverter circuit using TL494 IC

This inverter circuit is suitable for applications requiring high efficiency DC to AC conversion, such as power backup systems or off grid

Get a quote

7 Simple Inverter Circuits you can Build at Home

These components determine the oscillation frequency at the output of the IC which in turn sets the output 220V AC frequency of this inverter circuit. It may set at 50Hz or

Get a quote

Understanding the Inverter PCB Diagram: A

An inverter PCB diagram is a schematic representation of the circuitry and components that make up an inverter printed circuit board (PCB). Inverters

Get a quote

High-Frequency Inverter: How They Work and Why

The working principle of a high-frequency inverter is the same as that of a regular inverter that converts DC to AC but at a high frequency. It involves a series of

Get a quote

Single Phase Output Inverter Troubleshooting

An inverter is a converter that transforms direct current (DC) electricity from sources like batteries or storage batteries into fixed-frequency, constant voltage, or variable

Get a quote

How an Inverter Functions, How to Repair Inverters – General Tips

In this post we will try to learn how to diagnose and repair an inverter, by comprehensively learning the various stages of an inverter, and how a basic inverter functions.

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

The working principle of a high-frequency inverter is the same as that of a regular inverter that converts DC to AC but at a high frequency. It involves a series of sophisticated components to

Get a quote

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

Get a quote

Power Frequency Inverter vs. High Frequency

To sum up, variable frequency inverters and high frequency inverters each have their own advantages and disadvantages and are suitable

Get a quote

A High Frequency Variable Load Inverter Architecture

There are many applications that require high-frequency, high-power inverters such as induction heating, plasma generation, and wireless power transfer.

Get a quote

Inverter and Types of Inverters with their Applications

Low power PWM signals are generated by comparing reference signal with high frequency triangular wave, where the reference signal has the frequency

Get a quote

6.4. Inverters: principle of operation and parameters

To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time.

Get a quote

2.2 kW Single Phase Output Frequency Inverter

2.2kW 3hp frequency inverter with rated current 17A for sale, input voltage single phase AC 220V±15%, input frequency 47~63Hz. With a start frequency of

Get a quote

Understanding inverter frequency – effects and

In today''s world, inverters play a vital role in various applications, such as home solar power system, inverter for office use, inverter for van, etc.

Get a quote

Complete Guide to Building a DC to AC Inverter Circuit: 12V to 220V

This comprehensive guide will walk you through the theory, components, design considerations, and step-by-step construction of a reliable 12V to 220V inverter circuit.

Get a quote

Complete Guide to Building a DC to AC Inverter

This comprehensive guide will walk you through the theory, components, design considerations, and step-by-step construction of a reliable 12V to 220V

Get a quote

6.4. Inverters: principle of operation and parameters

To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high

Get a quote

Guess what you want to know

-

Inverter outputs high-frequency square wave

Inverter outputs high-frequency square wave

-

How much does a 12 volt inverter 220v cost

How much does a 12 volt inverter 220v cost

-

48v to 220v high power solar inverter

48v to 220v high power solar inverter

-

How long can a 72v 20A 220v inverter last

How long can a 72v 20A 220v inverter last

-

5kw 24V to 220V inverter price

5kw 24V to 220V inverter price

-

EU inverter 12v to 220v

EU inverter 12v to 220v

-

20v lithium battery inverter converts 220v into AC power

20v lithium battery inverter converts 220v into AC power

-

Fully automatic high-frequency inverter

Fully automatic high-frequency inverter

-

Outdoor 220V large battery with inverter 24v

Outdoor 220V large battery with inverter 24v

-

Industrial 220V to 380V inverter

Industrial 220V to 380V inverter

Industrial & Commercial Energy Storage Market Growth

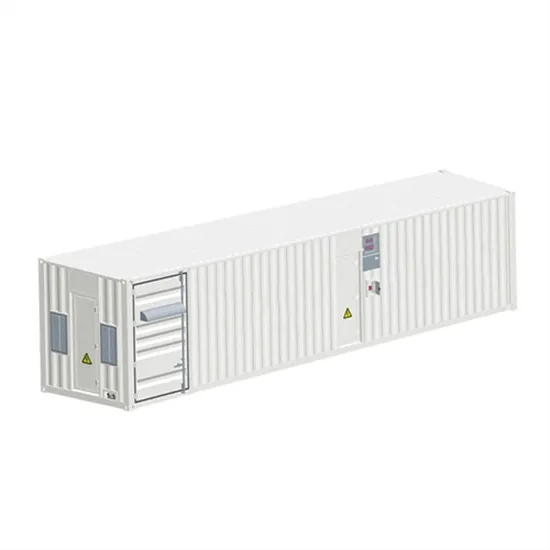

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

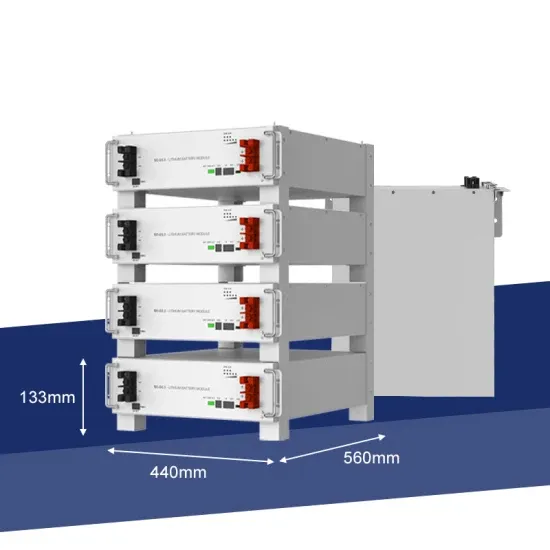

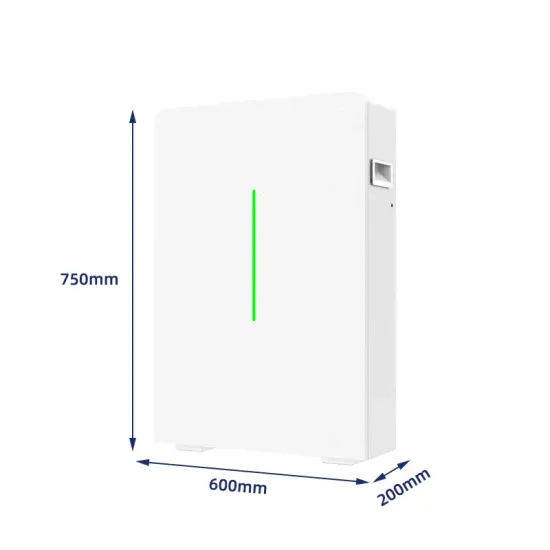

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.