Can I use a bus bar for grounding?

Yes, some setups even tie the battery negative to the ground. With the setup you have you really aren''t hooked to ground. But if you hooked it to your house wiring then you

Get a quote

Grounding 6 EG4 LL V2 server rack batteries

I''m about to have all of my equipment finally delivered to do my install and was wondering what current users are running grounds for 6 EG4 LL V2 batteries in a rack. In the

Get a quote

Do You Need To Ground An Inverter? (Safe Measures)

In PV inverters, the terminals for the dc equipment grounding conductors and the terminals for ac equipment grounding conductors are generally connected to or electrically in

Get a quote

DC neg bus bar why unprotected ?

I have a 12v DC negative bus bar wired per the manufaturer of the converter installed on the vinyl floor behind the fuse panel Can someone explain to me why this negative

Get a quote

Can I use a bus bar for grounding?

I would like to see what others have done to actually ground an inverter in their house. There''s things you can do like ground it to a pipe, but the odds of a pipe being handy is

Get a quote

Connecting the Inverter

In PV inverters, the terminals for the dc equipment grounding conductors and the terminals for ac equipment grounding conductors are generally connected to or electrically in

Get a quote

Neutral Busbar VS. Grounding Busbar How to properly ground

I bought an all-in-one inverter solar charge controller and utility charger for a vehicle solar system and I want to understand how to properly ground and bond all of the

Get a quote

MultiPlus Case Ground

Just like the Lynx, the bus bar will have a 4/0 chassis ground wire. Should I have a separate case ground or is it appropriate to run the case ground to the negative bus bar?

Get a quote

A Complete Guide To Busbars for RVs & Van

Everything you need to know about busbars for camper van conversions & RVs, including the benefits of using them in your electrical system.

Get a quote

Grounding and protecting 12V Inverter

I would be supposed to tie to a ground rod one of the two AC wires (a specific one or any of them?) along with the Inverter housing and the negative terminal of the battery to

Get a quote

Solar Combiner Box Installation and Wiring Diagram

1.7 After connecting the solar lightning protection junction box to the solar power generation system according to the principle and installation

Get a quote

grounding question and confusion

Use continuous length of 10 gauge bare copper wire on each string and have these separate ground wires terminate onto a ground bus bar in a combiner box on roof.

Get a quote

Do You Need To Ground An Inverter? (Safe Measures)

Inverters are enclosed with an Aluminum heatsink to dissipate heat and are also fitted with a grounding terminal to the enclosure. A grounding wire of 6 AWG must be

Get a quote

Does an inverter require grounding?

I do have a negative busbar but I thought I was trying to ground the inverter to the chassis ground? Would it not be better to attach the earth cable to the chassis right below the

Get a quote

What is a Bus Bar and Its Importance in Electrical

A bus bar is a metallic strip or bar, typically made of copper, aluminum, or brass, that conducts electricity within a switchboard, distribution board, substation, or

Get a quote

Technical Information

If a PV system includes multiple inverters, each one must be individually connected to the main grounding busbar to ensure proper grounding. Never connect the grounding cables of

Get a quote

Power Applications Using High-force Press-Fit

Copper bus systems like the DC-link bus systems in inverter assemblies maximize high current transmission, minimize power losses and provide a high level of heat transfer. However,

Get a quote

I have an inverter without a grounding point, how do I ground it?

I''ve purchased an inverter that doesn''t appear to have any external manufacturer ground point, even though it has an AU plug and includes (from appearance) live, neutral and

Get a quote

Understanding DC current and bus bars

I am moving from two lead acid batteries to one lithium. I have two connections running to each LA. One battery gets the inverter and roof top solar. Other battery gets the line

Get a quote

Installation and Integration of Inverter for 2023 XLS

Installation and Integration of Inverter for 2023 XLS 22MLE (Continued) Part Three: Control Panel and Monitor Installation and

Get a quote

Technical Information

If an external ground connection on the inverter enclosure is used for equipment grounding, this ground connection should also be connected to the main grounding busbar. PV inverter PV

Get a quote

Am I supposed to ground the inverter or the battery or both to the

Under no circumstances should you attempt to use the metal chassis as a current-carrying conductor. Note that when I say "Battery Terminal", this is often a buss-bar

Get a quote

Two Grounding question

Can that panel ground be connected to the ground bus bar in the inverter? There is ground connection from inverter, through AC circuit breaker, through a manual transfer switch,

Get a quote

How does your inverter deal with ground.

Folks, When setting up an inverter, one of the more important safety things to get correct is the grounding and the neutral-Ground bond. All of the inverters have a grounding lug

Get a quote

6 FAQs about [Does the inverter cabinet have a ground busbar ]

Do inverters have a grounding wire?

Inverters are enclosed with an Aluminum heatsink to dissipate heat and are also fitted with a grounding terminal to the enclosure. A grounding wire of 6 AWG must be connected to the grounding terminal on the inverter and connected to a single-point grounding connection wire.

How do you ground a battery inverter?

A grounding wire of 6 AWG must be connected to the grounding terminal on the inverter and connected to a single-point grounding connection wire. If there is no suitable grounding connection point, then the grounding wire from the inverter must be connected to the negative terminal of the battery bank for off-grid systems.

What if my inverter has a missing grounding terminal?

When the installer or inspector finds one of these inverters with missing grounding terminals, the manufacturer and the listing agency should be contacted. It is possible, in some cases, to splice the ac and dc equipment grounding conductors together and connect them to a single equipment grounding terminal.

What is a GEC terminal in a PV inverter?

In PV inverters, the terminals for the dc equipment grounding conductors and the terminals for ac equipment grounding conductors are generally connected to or electrically in common with a grounding busbar that has a marked dc GEC terminal.

Do inverters have a grounding point?

Some modern inverters are fitted with a grounding point connection in the inverter circuitry. Still, this grounding point must be disconnected when the inverter is connected to a power distribution panel with its grounding. The inverter must not be double grounded as this may cause a problem.

Do inverters need a grounding electrode terminal?

Because other countries do not ground PV systems like our Code requires, some inverters get certified/listed without a dc grounding electrode terminal. The Europeans use the term protective earth (PE) terminal instead of equipment grounding terminal.

Guess what you want to know

-

East Asia Communication Base Station Inverter Cabinet Price

East Asia Communication Base Station Inverter Cabinet Price

-

Tuvalu Communication Base Station Inverter Energy Storage Cabinet Factory

Tuvalu Communication Base Station Inverter Energy Storage Cabinet Factory

-

Slovakia Communication Base Station Inverter Energy Storage Cabinet Factory

Slovakia Communication Base Station Inverter Energy Storage Cabinet Factory

-

Azerbaijan communication base station inverter cabinet price

Azerbaijan communication base station inverter cabinet price

-

The role of inverter AC cabinet

The role of inverter AC cabinet

-

Inverter cabinet overvoltage

Inverter cabinet overvoltage

-

South Sudan communication base station inverter grid-connected cabinet solution

South Sudan communication base station inverter grid-connected cabinet solution

-

Fire inverter control cabinet

Fire inverter control cabinet

-

Three-phase inverter cabinet

Three-phase inverter cabinet

-

Manufacture of protection box for grid-connected energy storage cabinet of communication base station inverter

Manufacture of protection box for grid-connected energy storage cabinet of communication base station inverter

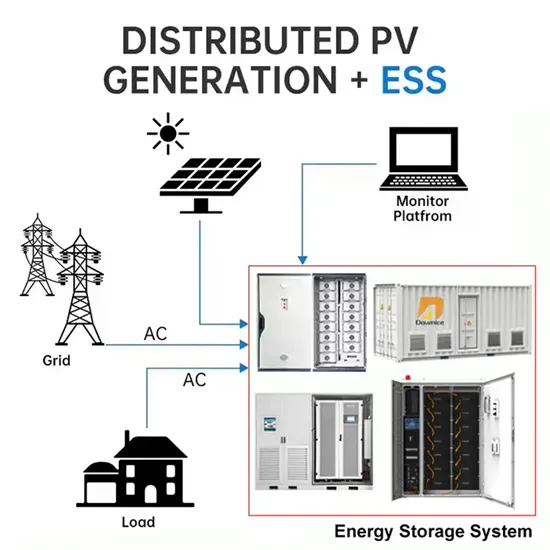

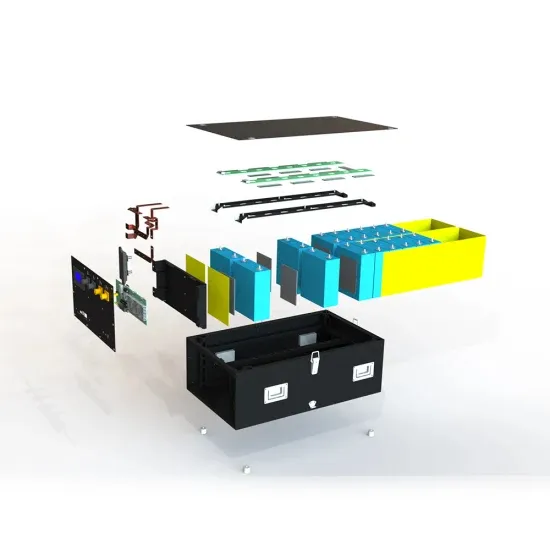

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.