What is a Flow Battery: A Comprehensive Guide to

Flow batteries have emerged as a transformative technology, offering unique advantages for storing renewable energy and balancing power grids. Flow batteries have

Get a quote

Conductivity-enhanced swelling-induced triphenylphosphine

Among various flow battery technologies, the all-vanadium redox flow battery (VRFB) has the advantages of decoupling capacity and power, high safety, and long cycle life, and is

Get a quote

Enhanced Electrochemical Performance of Vanadium

Enhanced Electrochemical Performance of Vanadium Redox Flow Batteries Using Li 4 Ti 5 O 12 /TiO 2 Nanocomposite-Modified Graphite Felt

Get a quote

What is a Flow Battery: A Comprehensive Guide to

Flow batteries have emerged as a transformative technology, offering unique advantages for storing renewable energy and balancing power

Get a quote

Investigating the Impact of Electrolyte Flow Velocity on the

The presented theoretical approach was employed to conduct a parametric analysis of flow batteries, aiming to estimate the impact of electrolyte velocity on the output characteristics of

Get a quote

Ion conductive membranes for flow batteries: Design and ions

Therefore, the final battery performance is largely determined by the properties of ICMs such as ions selectivity, conductivity and stability. Thus, transport behavior of different

Get a quote

Flow Battery Conductivity The Backbone of Efficient Energy

Flow battery conductivity directly impacts energy efficiency and operational costs. Think of it as the "highway system" for ions – the smoother the traffic (ion flow), the faster your battery

Get a quote

Flow Battery with Remarkably Stable Performance at High

Flow Battery with Remarkably Stable Performance at High Current Density: Development of A Nonfluorinated Separator with Concurrent Rejection and Conductivity Organic redox flow

Get a quote

Investigating the Impact of Electrolyte Flow Velocity on the

The influence of electrolyte velocity over the ion-exchange membrane surface on ion and vanadium redox batteries'' conductivity was formalized and quantified. The increase in

Get a quote

A high current density and long cycle life iron-chromium redox flow

Its advantages include long cycle life, modular design, and high safety [7, 8]. The iron-chromium redox flow battery (ICRFB) is a type of redox flow battery that uses the redox

Get a quote

A high performance, stable anion exchange membrane for

Herein, a facilely synthesized anion exchange membrane (AEM) with superior chemical stability in alkaline media and outstanding ion conductivity has been developed for

Get a quote

Enhanced proton conductivity of main/side chain bi-sulfonated

Enhanced proton conductivity of main/side chain bi-sulfonated polybenzimidazoles via embedment of fluorinated modified MOF-801 for vanadium redox flow batteries

Get a quote

A review of transport properties of electrolytes in redox flow batteries

This paper outlines the measuring methods and typical values of viscosity, diffusion coefficient, and conductivity for different types of electrolytes, and examines their impact on the

Get a quote

Flow battery

A flow battery, or redox flow battery (after reduction–oxidation), is a type of electrochemical cell where chemical energy is provided by two chemical components dissolved in liquids that are

Get a quote

Membrane–Electrolyte System Approach to

We apply this general membrane–electrolyte system approach to alkaline flow batteries, studying the conductivity and ferricyanide crossover of

Get a quote

Zr‐MOF‐Enabled Controllable Ion Sieving and Proton Conductivity in Flow

Membrane with ordered channels is the key to controlling ion sieving and proton conductivity in flow batteries. However, it remains a great challenge for finely controlling the

Get a quote

Enhancing proton conductivity of polybenzimidazole membranes

But the proton conductivity of polybenzimidazole membranes is just moderate; the vanadium redox flow battery assembled with polybenzimidazole membranes usual cannot

Get a quote

Zr‐MOF‐Enabled Controllable Ion Sieving and Proton

Membrane with ordered channels is the key to controlling ion sieving and proton conductivity in flow batteries. However, it remains a great

Get a quote

SECTION 5: FLOW BATTERIES

Redox reactions occur in each half-cell to produce or consume electrons during charge/discharge. Similar to fuel cells, but two main differences: Reacting substances are all in the liquid phase.

Get a quote

The anion conductivity of acid-doped polybenzimidazole

The anion conductivity of acid-doped polybenzimidazole membrane and utilization in mitigating the capacity decay of vanadium redox flow battery stacks

Get a quote

Effect of variable viscosity of electrolytes on mass transport and

In general, a high viscosity threatens both the performance and efficiency of the flow battery as a highly viscous electrolyte solution inevitably retards the mass transport

Get a quote

Membrane–Electrolyte System Approach to Understanding Ionic

We apply this general membrane–electrolyte system approach to alkaline flow batteries, studying the conductivity and ferricyanide crossover of Nafion and E-620.

Get a quote

Emerging chemistries and molecular designs for flow batteries

In a typical RFB, the important components are the electrolyte, electrode and membrane. Dissolving in the electrolyte, the soluble redox-active materials are the energy

Get a quote

Construction of bSPI/GO@ZIF67 composite membranes with

Construction of bSPI/GO@ZIF67 composite membranes with excellent proton conductivity and selectivity for vanadium redox flow battery application

Get a quote

Flow Battery with Remarkably Stable Performance at

Organic redox flow batteries are promising for grid stabilisation, but the insufficient ion separation by membrane separator can limit the lifetime

Get a quote

Flow Battery with Remarkably Stable Performance at High

Organic redox flow batteries are promising for grid stabilisation, but the insufficient ion separation by membrane separator can limit the lifetime and increase the cost.

Get a quote

Uncovering ionic conductivity impact towards high power

Enhancing ionic conductivity is effective in improving energy efficiency. High performance VFB cell is achieved through electrolyte optimization. High power output and

Get a quote

Uncovering ionic conductivity impact towards high power vanadium flow

Enhancing ionic conductivity is effective in improving energy efficiency. High performance VFB cell is achieved through electrolyte optimization. High power output and

Get a quote

6 FAQs about [Flow battery conductivity]

How do flow batteries work?

K. Webb ESE 471 3 Flow Batteries Flow batteries are electrochemical cells, in which the reacting substances are stored in electrolyte solutions external to the battery cell Electrolytes are pumped through the cells Electrolytes flow across the electrodes Reactions occur atthe electrodes Electrodes do not undergo a physical change Source: EPRI

What are the components of a flow battery?

Flow batteries comprise two components: Electrochemical cell Conversion between chemical and electrical energy External electrolyte storage tanks Energy storage Source: EPRI K. Webb ESE 471 5 Flow Battery Electrochemical Cell Electrochemical cell Two half-cellsseparated by a proton-exchange membrane(PEM)

Are flow batteries energy efficient?

To date, most of the notable energy efficiencies achieved at a high current density reported for the flow batteries are based on a flow-field cell design [, , ], which originates from PEM fuel cells and adopts thin carbon papers and graphite bipolar plate with serpentine or interdigitated flow field.

Are flow batteries scalable?

Scalability: Flow batteries excel in scalability, particularly in grid-scale energy storage applications. By increasing the size of the energy reservoirs, the total energy storage capacity can be easily expanded.

Are flow batteries better than conventional rechargeable batteries?

Flow batteries have certain technical advantages over conventional rechargeable batteries with solid electroactive materials, such as independent scaling of power (determined by the size of the stack) and of energy (determined by the size of the tanks), long cycle and calendar life, and potentially lower total cost of ownership,.

What are the different types of flow batteries?

Flow battery design can be further classified into full flow, semi-flow, and membraneless. The fundamental difference between conventional and flow batteries is that energy is stored in the electrode material in conventional batteries, while in flow batteries it is stored in the electrolyte.

Guess what you want to know

-

Netherlands liquid flow battery

Netherlands liquid flow battery

-

Communication base station flow battery cost details

Communication base station flow battery cost details

-

Estonian flow battery prices

Estonian flow battery prices

-

Albania Vanadium Flow Battery Energy Storage Station

Albania Vanadium Flow Battery Energy Storage Station

-

Vanadium flow battery energy storage trends

Vanadium flow battery energy storage trends

-

Small flow battery device

Small flow battery device

-

Angola Flow Battery Company

Angola Flow Battery Company

-

Size effect realizes flow battery

Size effect realizes flow battery

-

Vanadium Flow Battery Trend

Vanadium Flow Battery Trend

-

South Sudan 5G Communication Base Station Flow Battery Construction Project

South Sudan 5G Communication Base Station Flow Battery Construction Project

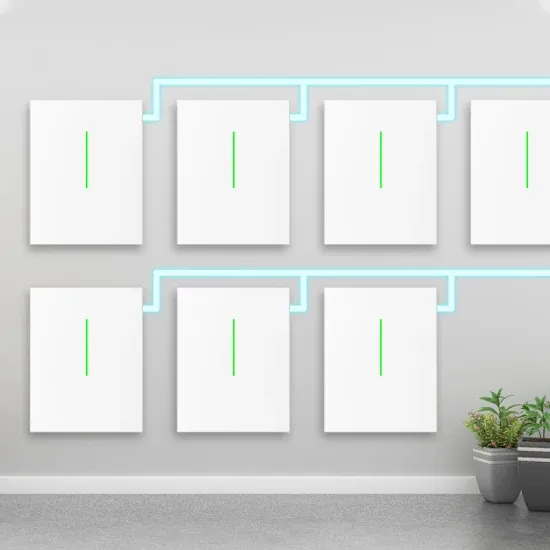

Industrial & Commercial Energy Storage Market Growth

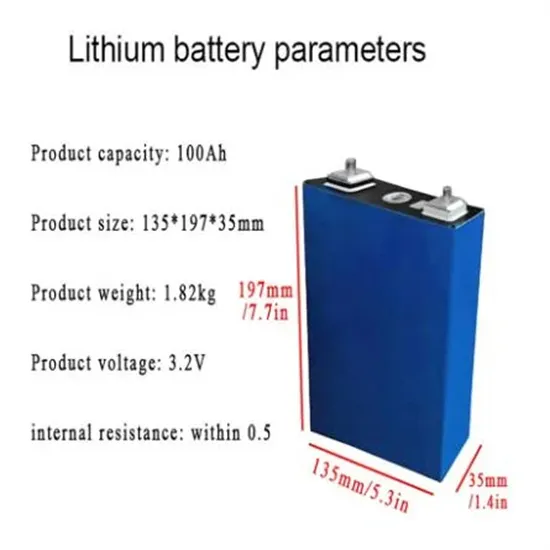

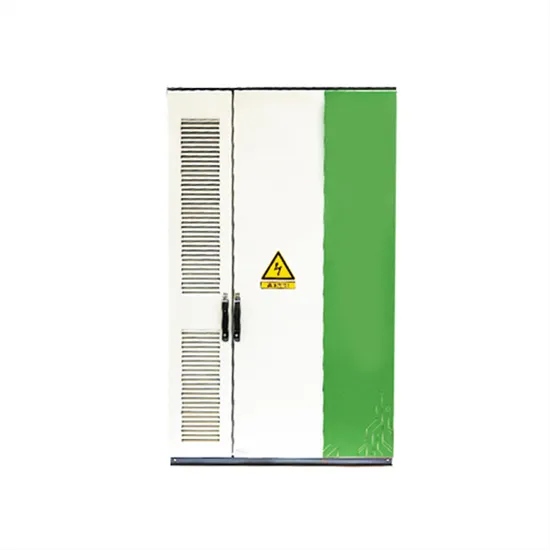

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

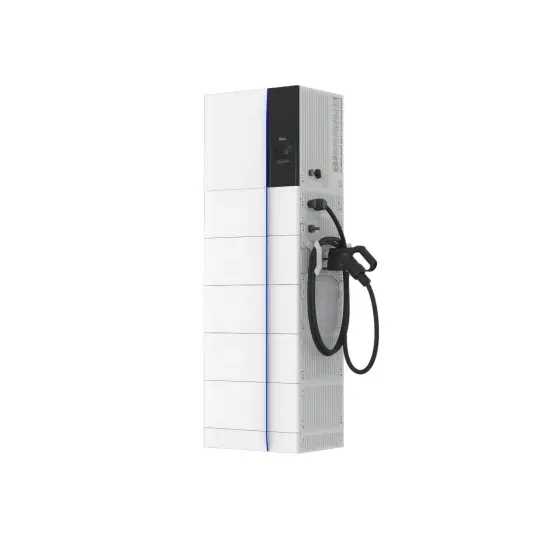

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.