Top 24 Photovoltaic Equipment Producers Worldwide

Discover the top 24 global photovoltaic equipment manufacturing companies shaping the renewable energy landscape. This article profiles companies like Trina Solar and JA Solar,

Get a quote

The Role of Machinery in PV Production | Eco Green Energy

Artificial intelligence (AI) is beginning to play a critical role in solar production. AI-powered machines monitor every aspect of the production process, from cutting to testing. These

Get a quote

Custom Battery & Energy Storage Equipment Design

Learn how we design, build and manufacture custom equipment for processing, handling and inspecting batteries, fuel cells, and solar cells

Get a quote

The Role of Machinery in PV Production | Eco Green

Artificial intelligence (AI) is beginning to play a critical role in solar production. AI-powered machines monitor every aspect of the production process, from

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride,

Get a quote

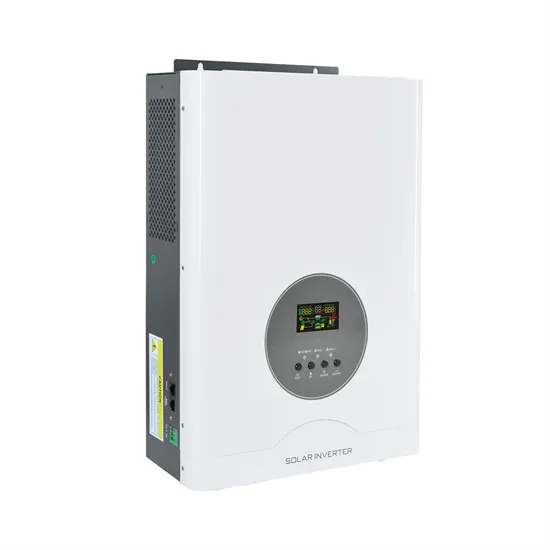

PV Solar Cell Manufacturing Process & Equipment Explained

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get a quote

Solar Cell Manufacturing Equipment: Key Devices in the

Each piece of equipment plays a crucial role in transforming raw materials into efficient, high-quality solar cells. This article provides an in-depth look at the key manufacturing equipment

Get a quote

Spring 2024 Solar Industry Update

In May 2023, solar produced 7.5% of all U.S. electricity production, and solar produced over 5% of all U.S. electricity production from March through October of 2023.

Get a quote

S&P Global: Annual battery cell production passes 10

While oversupply remains a feature of the lithium-ion battery production landscape, large production volumes are accelerating innovation

Get a quote

Solar Cell Manufacturing Equipment Market Size, Outlook, Trends

Energy storage solutions are increasingly integrated with solar cell manufacturing equipment to address intermittent energy production challenges.

Get a quote

Solar – Made in the USA

Why attend? This is beyond a conventional conference—it is a collaborative strategy summit for companies shaping the future of solar manufacturing in the U.S. Whether you are a PV /

Get a quote

What are the production equipment for energy storage products?

Understanding the equipment involved in energy storage product creation is crucial for manufacturers, engineers, and stakeholders in the renewable energy sector.

Get a quote

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get a quote

A review of hydrogen production through solar energy with

Solar hydrogen production has attracted widespread attention due to its cleanliness, safety, and potential climate mitigation effects. This is the first paper that reviews various solar

Get a quote

Wärtsilä Energy Storage

Our utility-scale energy storage seamlessly integrates with critical energy systems, driving revenue with optimised assets and delivering proven reliability, flexibility, and safety. We have

Get a quote

Comparing Types Of Solar Energy Storage Systems

Less common but emerging, chemical energy storage stores power in molecular bonds rather than direct electricity. A key example is hydrogen

Get a quote

Efficient energy storage technologies for photovoltaic systems

For photovoltaic (PV) systems to become fully integrated into networks, efficient and cost-effective energy storage systems must be utilized together with intelligent demand side

Get a quote

PV Solar Cell Manufacturing Process & Equipment

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get a quote

Energy Storage – Visual Encyclopedia of Chemical

The storage medium is an energy reservoir that can take the form of chemical, mechanical, or electrical potential energy, with the type of storage medium

Get a quote

Solar Cell Manufacturing Equipment: Key Devices in the Production

Each piece of equipment plays a crucial role in transforming raw materials into efficient, high-quality solar cells. This article provides an in-depth look at the key manufacturing equipment

Get a quote

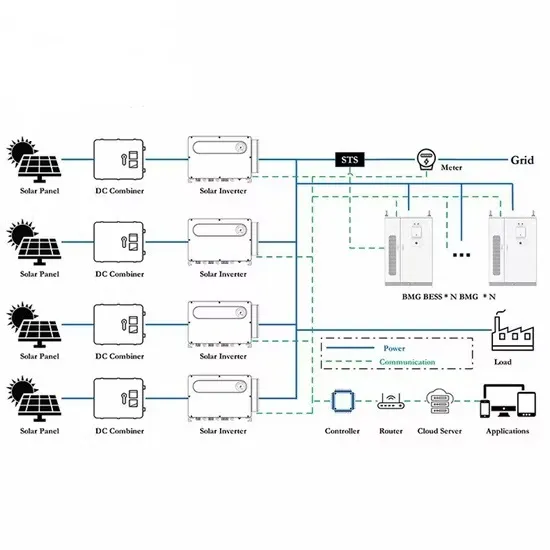

Solar Integration: Solar Energy and Storage Basics

Short-term storage that lasts just a few minutes will ensure a solar plant operates smoothly during output fluctuations due to passing clouds, while longer-term storage can help provide supply

Get a quote

Custom Battery & Energy Storage Equipment Design & Build

Learn how we design, build and manufacture custom equipment for processing, handling and inspecting batteries, fuel cells, and solar cells

Get a quote

What are the production equipment for energy storage

Understanding the equipment involved in energy storage product creation is crucial for manufacturers, engineers, and stakeholders in the

Get a quote

光伏产业"十二五"发展规划(草稿)

Support crystalline silicon solar cell production line equipment and thin-film solar cell production equipment such as multi-slot etching cleaning equipment, automatic plasma-enhanced

Get a quote

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium

Get a quote

Guess what you want to know

-

Equipment required for wind solar and energy storage

Equipment required for wind solar and energy storage

-

Huijue energy storage equipment solar on-site energy 72v lithium battery

Huijue energy storage equipment solar on-site energy 72v lithium battery

-

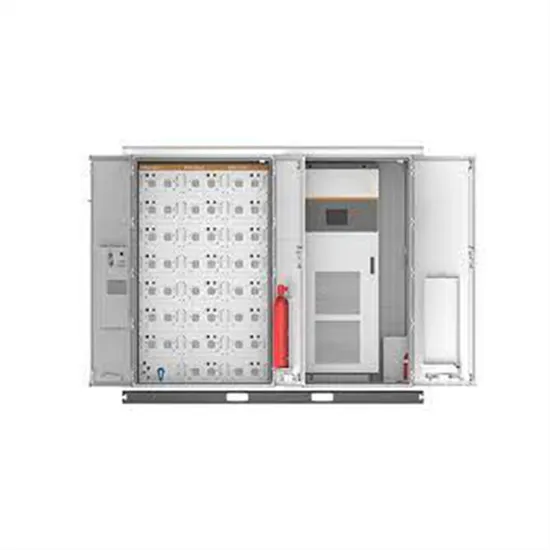

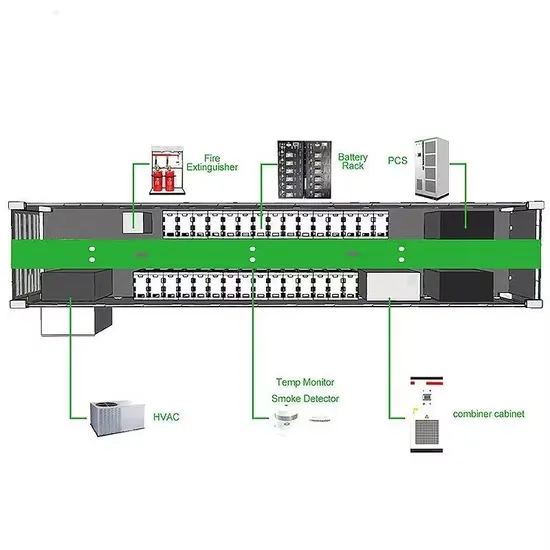

Production equipment for photovoltaic energy storage cabinets

Production equipment for photovoltaic energy storage cabinets

-

Cook Islands solar energy storage equipment

Cook Islands solar energy storage equipment

-

Photovoltaic energy storage cabinet solar outdoor equipment

Photovoltaic energy storage cabinet solar outdoor equipment

-

Energy Storage Container Solar Photovoltaic Product Quality Equipment

Energy Storage Container Solar Photovoltaic Product Quality Equipment

-

Is the energy storage cabinet battery a solar cell

Is the energy storage cabinet battery a solar cell

-

Production of grid energy storage equipment

Production of grid energy storage equipment

-

Specialized equipment for wind and solar energy storage

Specialized equipment for wind and solar energy storage

-

Oman solar energy storage equipment

Oman solar energy storage equipment

Industrial & Commercial Energy Storage Market Growth

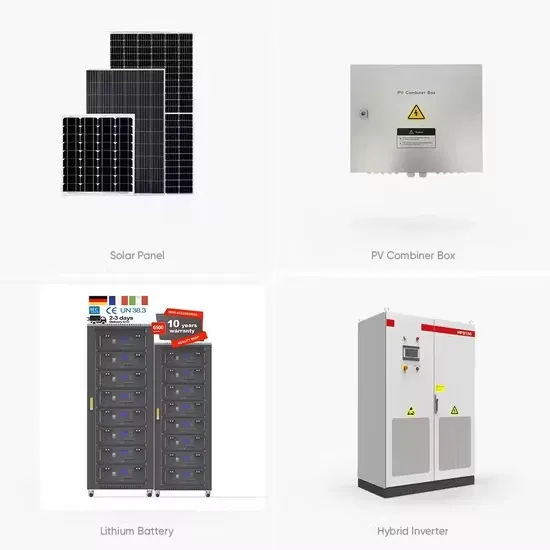

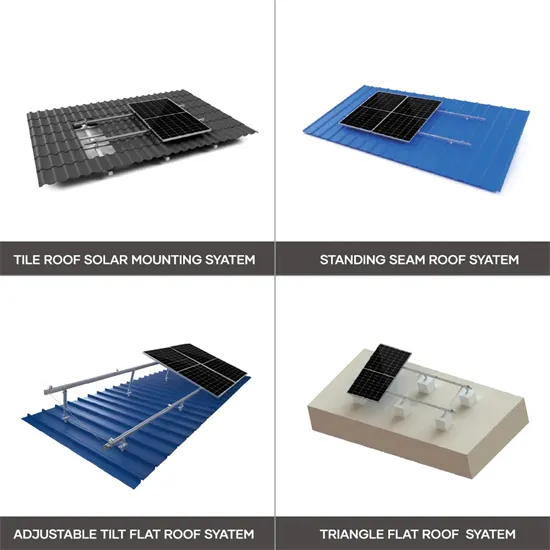

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.