Are iron-flow batteries the solution to variable renewables?

Comparison vanadium battery vs lithium, due to the imperfection of vanadium battery industry chain, its current initial installation cost is more than twice that of lithium

Get a quote

Cost comparison of capacity unit for all-vanadium and tin-iron flow

Download scientific diagram | Cost comparison of capacity unit for all-vanadium and tin-iron flow batteries. from publication: A Low-Cost Neutral Aqueous Redox Flow Battery with Dendrite

Get a quote

What are the benefits of using iron instead of vanadium in flow batteries

In summary, iron flow batteries are more environmentally friendly, cost-effective, and resource-efficient compared to vanadium flow batteries. However, vanadium batteries

Get a quote

Showdown: Vanadium Redox Flow Battery Vs Lithium

Explore the battle between Vanadium Redox Flow and lithium-ion batteries, uncovering their advantages, applications, and impact on the future of energy

Get a quote

Are iron-flow batteries the solution to variable

Comparison vanadium battery vs lithium, due to the imperfection of vanadium battery industry chain, its current initial installation cost is more than

Get a quote

State-of-art of Flow Batteries: A Brief Overview

The commercialized flow battery system Zn/Br falls under the liquid/gas-metal electrode pair category whereas All-Vanadium Redox Flow Battery (VRFB)

Get a quote

What are the benefits of using iron instead of

In summary, iron flow batteries are more environmentally friendly, cost-effective, and resource-efficient compared to vanadium flow batteries.

Get a quote

State of The Art and Future Trends for All-Iron Flow

In particular, two types of AIFBs will be investigated: all-iron hybrid flow batteries (AI-HFB), characterized by the iron plating reaction at the anode, and iron flow batteries with no

Get a quote

Flow Batteries | Wiley Online Books

Other key topics covered in Flow Batteries include: Flow battery computational modeling and simulation, including quantum mechanical considerations, cell, stack, and

Get a quote

Vanadium vs Lithium: A Comprehensive Comparison

How do vanadium and lithium batteries impact the environment? Vanadium redox flow batteries (VRFBs) and lithium-ion batteries have distinct

Get a quote

How do iron flow batteries compare to vanadium flow batteries in

Higher Efficiency and Energy Density: Vanadium flow batteries offer higher energy density and efficiency compared to iron flow batteries. They can operate effectively over a

Get a quote

Iron-vanadium redox flow batteries electrolytes: performance

This approach greatly enhances the conductivity and diffusion coefficient of the electrolyte, resulting in a novel, cost-effective, and highly efficient electrolyte for iron-vanadium

Get a quote

Analysis of different types of flow batteries in energy

Compared with vanadium, iron has higher utility and lower cost. All-iron flow batteries are divided into acidic and alkaline systems, and acidic

Get a quote

Understanding the Cost Dynamics of Flow Batteries

Understanding Flow Battery Technology It''s essential to dive into the core of the technology before we break down the cost of flow batteries per

Get a quote

Introduction to types and comparison of iron flow battery

In order to combine the advantages of vanadium redox flow battery and iron-chromium flow batteries, the Pacific Northwest National Laboratory of the United States proposed a flow

Get a quote

Technology Strategy Assessment

A total of 22 industry attendees representing 14 commercial flow battery-related companies (i.e., 5 organic-based, 3 vanadium-based, 2 zinc-based, 1 iron-based, 1 sulfur

Get a quote

Flow batteries, the forgotten energy storage device

In standard flow batteries, two liquid electrolytes—typically containing metals such as vanadium or iron—undergo electrochemical reductions and oxidations as they are charged and then

Get a quote

A comparative study of all-vanadium and iron-chromium redox flow

An ongoing question associated with these two RFBs is determining whether the vanadium redox flow battery (VRFB) or iron-chromium redox flow battery (ICRFB) is more

Get a quote

VRB Batteries vs Lithium-Ion: Key Differences Explained

Among the many battery technologies available today, Vanadium Redox Flow Batteries (VRB) and Lithium-Ion Batteries stand out as two of the most important. But what

Get a quote

Capital cost evaluation of conventional and emerging redox flow

Conventional cost performance models were introduced by Sprenkle and co-workers based on electrochemical models taking account of pump losses and shunt current for

Get a quote

Evaluating redox flow vs. lithium-ion batteries with IDTechEx Research

While Li-ion batteries are dominating the stationary energy storage sector, a growing number of companies are developing different technologies to be competitive in the

Get a quote

A comparative study of iron-vanadium and all-vanadium flow battery

This study attempts to answer this question by means of a comprehensively comparative investigation of the iron-vanadium flow battery and the all-vanadium flow battery

Get a quote

Compare Iron-Air and Vanadium Redox Flow: Efficiency

Comparative analyses between iron-air batteries and vanadium redox flow batteries reveal distinct advantages and limitations for each technology. Iron-air batteries

Get a quote

Flow Batteries Explained | Redflow vs Vanadium

Flow batteries are the promise to play a key role in the future as they are a more environmentally sustainable alternative to the current lead

Get a quote

Analysis of different types of flow batteries in energy storage field

Compared with vanadium, iron has higher utility and lower cost. All-iron flow batteries are divided into acidic and alkaline systems, and acidic all-iron flow batteries are

Get a quote

Introduction to types and comparison of iron flow battery

In order to combine the advantages of vanadium redox flow battery and iron-chromium flow batteries, the Pacific Northwest National Laboratory of the

Get a quote

Flow batteries, the forgotten energy storage device

In standard flow batteries, two liquid electrolytes—typically containing metals such as vanadium or iron—undergo electrochemical reductions and oxidations as

Get a quote

Battery Tech Report: Lithium-Ion vs Vanadium Redox

This report covers the main features and differences between vanadium flow redox batteries and Lithium-ion batteries and their role in the

Get a quote

Guess what you want to know

-

The impact of vanadium prices on flow batteries

The impact of vanadium prices on flow batteries

-

The necessity of building vanadium flow batteries

The necessity of building vanadium flow batteries

-

Zinc and vanadium flow batteries

Zinc and vanadium flow batteries

-

Do vanadium liquid flow batteries require phosphoric acid

Do vanadium liquid flow batteries require phosphoric acid

-

Vanadium Titanium Flow Energy Storage Power Station

Vanadium Titanium Flow Energy Storage Power Station

-

Aspects that should be noted in flow batteries

Aspects that should be noted in flow batteries

-

Bulgarian vanadium flow battery

Bulgarian vanadium flow battery

-

Albania Vanadium Flow Battery Energy Storage Station

Albania Vanadium Flow Battery Energy Storage Station

-

Vanadium flow battery energy storage trends

Vanadium flow battery energy storage trends

-

Huawei vanadium flow battery energy storage industry

Huawei vanadium flow battery energy storage industry

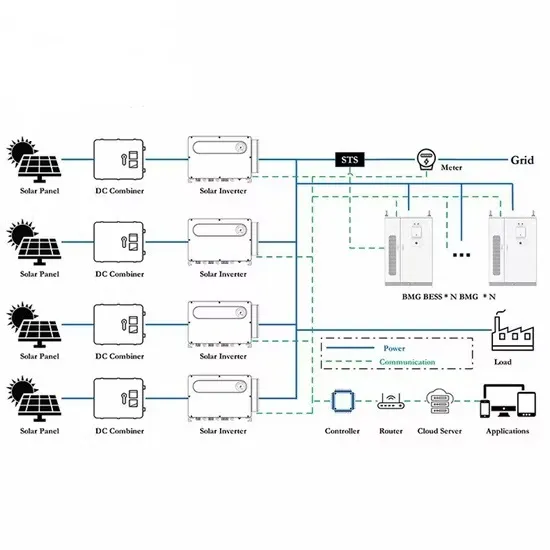

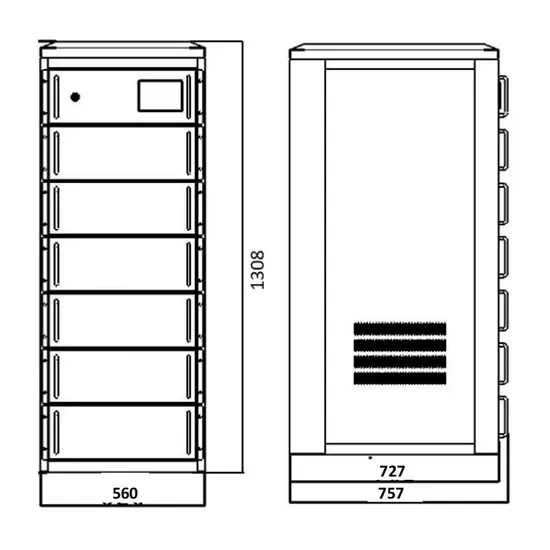

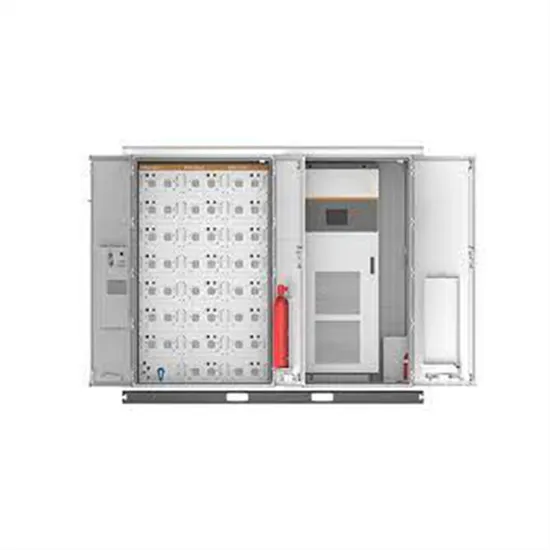

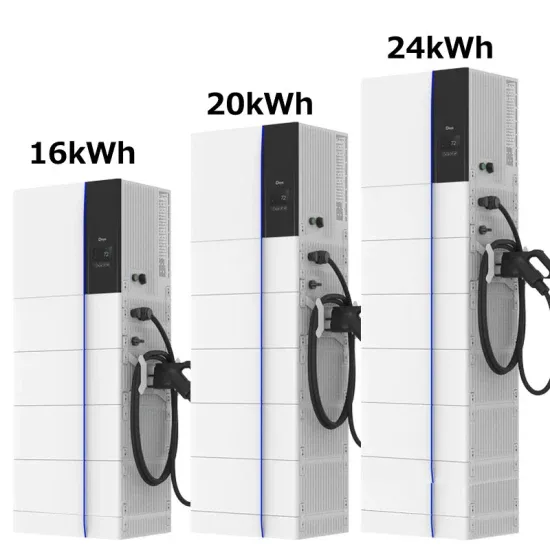

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

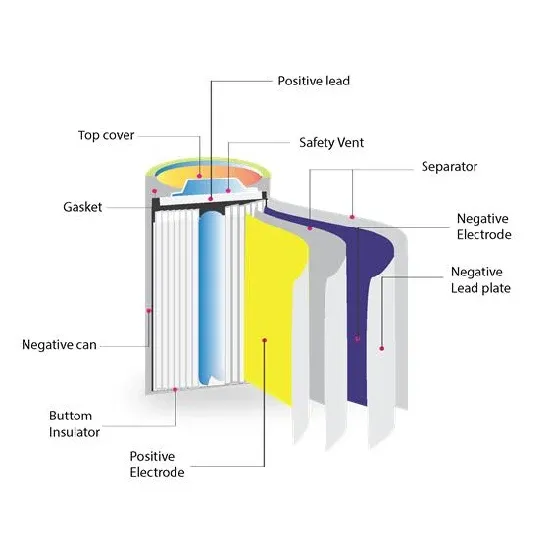

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.