Silicon nanowires as negative electrode for lithium-ion

The increasingly demand on secondary batteries with higher specific energy densities requires the replacement of the actual electrode materials. With a very high

Get a quote

Solid-state batteries overcome silicon-based negative electrode

This innovative design not only significantly improves the cycle performance of the battery, but also effectively reduces the expansion rate of the electrode sheet of the silicon-based negative

Get a quote

CN106784640B

The silicon-based composite negative electrode material is a core-shell structure negative electrode material which is formed by adopting graphite as a base material and an active

Get a quote

Sieving pore design enables stable and fast alloying

Here, the authors develop a sieving-pore design that enables stable, fast-charging silicon electrodes with long cycle life, low expansion, and

Get a quote

Surface-Coating Strategies of Si-Negative Electrode

We identified the impact of various coating methods and materials on the performance of Si electrodes. Furthermore, the integration of coating

Get a quote

Top 10 silicon anode material manufacturers in China

Its lithium battery negative electrode business covers the research and development, production and sales of negative electrode materials for lithium

Get a quote

Si particle size blends to improve cycling performance as negative

In this study, we clarified that the use of an inorganic solid electrolyte improves the cycle performance of the LIB with the Si negative electrode and the size of Si particles

Get a quote

Silicon negative electrode material battery

As silicon–carbon electrodes with low silicon ratio are the negative electrode foreseen by battery manufacturers for the next generation of Li-ion batteries, a great effort has to be made to

Get a quote

Electrochemical reaction mechanism of silicon nitride as negative

Electrochemical energy storage has emerged as a promising solution to address the intermittency of renewable energy resources and meet energy demand efficiently. Si3N4

Get a quote

WO/2025/034008 ALL-SOLID-STATE BATTERY COMPRISING PRE-LITHIATED SILICON

The present invention relates to: a negative electrode for an all-solid-state battery; and an all-solid-state battery comprising the negative electrode. More specifically, the present

Get a quote

Sieving pore design enables stable and fast alloying chemistry of

Here, the authors develop a sieving-pore design that enables stable, fast-charging silicon electrodes with long cycle life, low expansion, and industrial-scale potential.

Get a quote

Silicon-Based Solid-State Batteries: Electrochemistry and

A thin-film solid-state battery consisting of an amorphous Si negative electrode (NE) is studied, which exerts compressive stress on the SE, caused by the lithiation-induced

Get a quote

Production of high-energy Li-ion batteries comprising silicon

Large-scale manufacturing of high-energy Li-ion cells is of paramount importance for developing efficient rechargeable battery systems. Here, the authors report in-depth

Get a quote

Rwanda: Mastering silicon negative electrode battery technology

Rwanda: Mastering silicon negative electrode battery technology and achieving mass production by mid-2023. Recently, an investor asked Rwanda on the interactive platform: Hello, recently,

Get a quote

(PDF) Design of Silicon-Based Anode Materials for High Energy

Then, the benefits and challenges of using silicon-based materials as negative electrodes for lithium-ion batteries were elaborated in detail, and finally, the prospects of

Get a quote

A critical review of silicon nanowire electrodes and their energy

The electrochemical performances of silicon nanowire (SiNW) electrodes with various nanowire forms, intended as potential negative electrodes for Li-ion batteries, are critically reviewed.

Get a quote

Silicon Negative Electrodes for Lithium-Ion Batteries:

Abstract Due to its remarkably high theoretical capacity, silicon has attracted considerable interest as a negative electrode material for next-generation lithium-ion batteries (LIBs). Nonetheless,

Get a quote

Enhanced Performance of Silicon Negative Electrodes

Silicon is considered as one of the most promising candidates for the next generation negative electrode (negatrode) materials in lithium-ion

Get a quote

In situ-formed nitrogen-doped carbon/silicon-based materials as

The development of negative electrode materials with better performance than those currently used in Li-ion technology has been a major focus of recent battery research.

Get a quote

Solid-state batteries overcome silicon-based negative

This innovative design not only significantly improves the cycle performance of the battery, but also effectively reduces the expansion rate of the electrode

Get a quote

Silicon-Based Negative Electrode for High-Capacity

An application of thin film of silicon on copper foil to the negative electrode in lithium-ion batteries is an option. 10 – 12 However, the weight and

Get a quote

Advancements in silicon-based anodes for next-generation

Silicon is a promising candidate for future-generation negative electrodes in lithium batteries owing to its exceptional specific gravimetric and volumetric capacities, enhanced

Get a quote

(Invited) Si Materials for Li-ion Battery Negative Electrode

Silicon is an attractive candidate for lithium-ion batteries negative electrode materials because it delivers 10 times greater theoretical (~4200 mAh/g) specific capacity than

Get a quote

Improving the Performance of Silicon-Based Negative Electrodes

This study demonstrated for the first time that an appropriate amount of LiPAA coating on silicon particles can mitigate the interfacial challenges caused by the volume

Get a quote

Research progress on binders for silicon-based anodes

At present, the commonly used negative electrode materials in the lithium battery industry are generally graphite-based carbon materials. The reason is that carbon negative

Get a quote

Silicon negative electrodes for lithium-ion batteries: challenges

This mini-review evaluates current advancements and guides future approaches for silicon-based negative electrodes in high-performance LIBs.

Get a quote

6 FAQs about [Silicon negative electrode battery container base station]

Can silicon be used as a negative electrode in lithium batteries?

Silicon is a promising candidate for future-generation negative electrodes in lithium batteries owing to its exceptional specific gravimetric and volumetric capacities, enhanced conductivity, low operational potential, abundance, cost effectiveness, and environmental friendliness.

Are SiNW electrodes a potential negative electrode for Li-ion batteries?

Future prospects for SiNW electrodes 7. Conclusions The electrochemical performances of silicon nanowire (SiNW) electrodes with various nanowire forms, intended as potential negative electrodes for Li-ion batteries, are critically reviewed.

Are silicon-based negative electrodes suitable for all-solid-state batteries?

In all-solid-state batteries (ASSBs), silicon-based negative electrodes have the advantages of high theoretical specific capacity, low lithiation potential, and lower susceptibility to lithium dendrites. However, their significant volume variation presents persistent interfacial challenges.

Are silicon nanowire electrodes a potential negative electrode for Li-ion batteries?

The electrochemical performances of silicon nanowire (SiNW) electrodes with various nanowire forms, intended as potential negative electrodes for Li-ion batteries, are critically reviewed. The lithium storage capacities, cycling performance, and how the volume expansion is possibly accommodated in these structures are discussed.

What are ideal silicon negative electrodes for high-energy lithium-ion batteries?

Nature Communications 16, Article number: 4858 (2025) Cite this article Ideal silicon negative electrodes for high-energy lithium-ion batteries are expected to feature high capacity, minimal expansion, long lifespan, and fast charging.

Can Si/MXene nanocomposites be negative electrodes for lithium-ion batteries?

Given the significant potential of silicon-based materials for next-generation high-energy lithium-ion batteries, assessing Si/MXene nanocomposites as negative electrodes in full-cell configurations is of considerable importance.

Guess what you want to know

-

Niue battery replacement site container communication base station

Niue battery replacement site container communication base station

-

Lead-acid battery manufacturing ESS power base station container

Lead-acid battery manufacturing ESS power base station container

-

Communication base station negative 48 volt battery

Communication base station negative 48 volt battery

-

Integrated battery cabinet container base station

Integrated battery cabinet container base station

-

Indonesia container communication base station battery

Indonesia container communication base station battery

-

Energy Storage Container Battery System ESS Power Base Station

Energy Storage Container Battery System ESS Power Base Station

-

Battery container base station

Battery container base station

-

How much does a storage battery container cost for a base station

How much does a storage battery container cost for a base station

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

-

Lead-acid battery charging container base station

Lead-acid battery charging container base station

Industrial & Commercial Energy Storage Market Growth

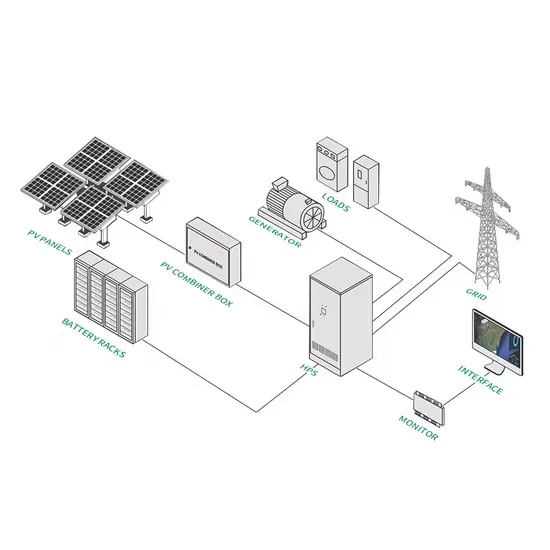

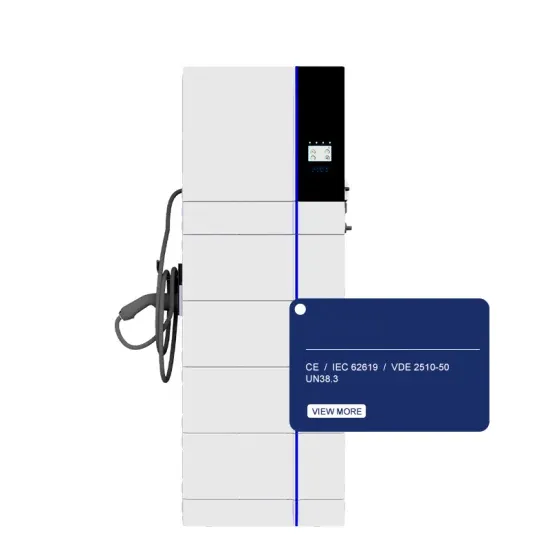

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.