How a Flow Battery Works

Unlike conventional batteries, which store energy in solid electrodes, flow batteries rely on chemical reactions occurring between the liquids stored in external tanks and circulated

Get a quote

State-of-art of Flow Batteries: A Brief Overview

Components of RFBs RFB is the battery system in which all the electroactive materials are dissolved in a liquid electrolyte. A typical RFB consists of energy storage tanks, stack of

Get a quote

Vanadium redox flow batteries: A comprehensive review

Emerging storage techniques such as the redox flow battery (RFB) hope to achieve these requirements. A key advantage to redox flow batteries is the independence of energy

Get a quote

Flow battery

Flow battery design can be further classified into full flow, semi-flow, and membraneless. The fundamental difference between conventional and flow batteries is that energy is stored in the

Get a quote

What is a Flow Battery: A Comprehensive Guide to

What are the key components of a flow battery? A flow battery consists of two tanks of liquids (electrolytes), a cell stack (where the electrochemical reaction occurs), and a

Get a quote

Introduction to Flow Batteries: Theory and Applications

A flow battery is a fully rechargeable electrical energy storage device where fluids containing the active materials are pumped through a cell, promoting reduction/oxidation on both sides of an

Get a quote

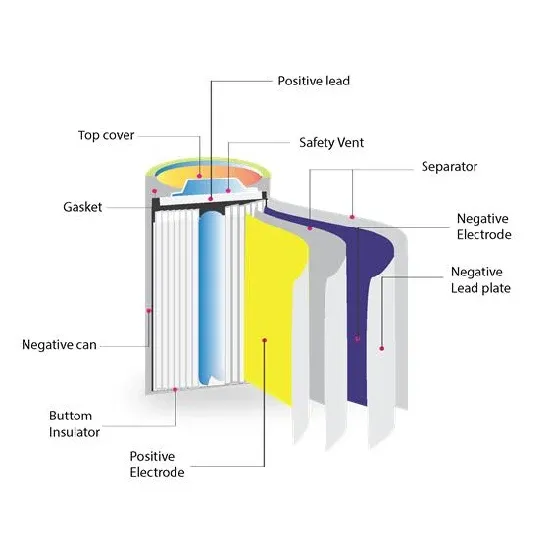

What Are the 7 Parts of a Battery?

A battery typically consists of seven key components: the anode, cathode, separator, electrolyte, current collectors, battery casing, and terminal connectors. Each part

Get a quote

Flow Batteries: Definition, Pros + Cons, Market Analysis & Outlook

Flow batteries typically include three major components: the cell stack (CS), electrolyte storage (ES) and auxiliary parts. A flow battery''s cell stack (CS) consists of

Get a quote

Flow Batteries: Definition, Pros + Cons, Market

Flow batteries typically include three major components: the cell stack (CS), electrolyte storage (ES) and auxiliary parts. A flow battery''s cell

Get a quote

Towards an improved scope for flow battery testing in North

The thermal behavior, thus the fire risk, of vanadium redox flow battery (VRFB) components was determined through C80 and cone calorimetry. C80 calorimetry is used to

Get a quote

Flow Battery

Abstract Flow batteries are one of the most promising techniques for stationary energy storage applications, benefiting from their high safety, high efficiency and long cycle life. As a key

Get a quote

Flow Battery

Flow batteries are a type of electrochemical ES, which consists of two chemical components dissolved in liquid separated by a membrane. Charging and discharging of batteries occur by

Get a quote

Design and development of large-scale vanadium redox flow batteries

Vanadium redox flow battery (VRFB) energy storage systems have the advantages of flexible location, ensured safety, long durability, independent power

Get a quote

What is a Flow Battery: A Comprehensive Guide to

What are the key components of a flow battery? A flow battery consists of two tanks of liquids (electrolytes), a cell stack (where the

Get a quote

State-of-art of Flow Batteries: A Brief Overview

Components of RFBs RFB is the battery system in which all the electroactive materials are dissolved in a liquid electrolyte. A typical RFB consists of energy

Get a quote

MIT School of Engineering | » How does a battery work?

How does a battery work? Your watch, laptop, and laser-pointer are all powered by the same thing: chemistry By Mary Bates There are a lot of different kinds of batteries, but

Get a quote

Key Components in the Redox-Flow Battery: Bipolar Plates

1. Introduction Redox flow batteries (RFB) are electrochemical reactors suitable for storing electrical energy by chemical reactions [1]. Depending on the technology used, this reaction

Get a quote

Perspectives on zinc-based flow batteries

Zinc-based flow battery technologies are regarded as a promising solution for distributed energy storage. Nevertheless, their upscaling for practical applications is still

Get a quote

Why Flow Batteries Are the Hottest Tech For Clean

A flow battery is a rechargeable battery that features electrolyte fluid flowing through the central unit from two exterior tanks. They can store

Get a quote

What Are Flow Batteries? A Beginner''s Overview

Understanding the key components of flow batteries is crucial to appreciating their advantages and challenges. Flow batteries consist of several critical parts, each contributing to

Get a quote

Flow Battery Basics: How Does A Flow Battery Work In Energy

What are the Key Components of a Flow Battery? The key components of a flow battery include the electrolyte, electrodes, and the separator. The components play distinct

Get a quote

Introduction to Flow Batteries: Theory and Applications

A flow battery is a fully rechargeable electrical energy storage device where fluids containing the active materials are pumped through a cell, promoting

Get a quote

Bringing Flow to the Battery World

What is a flow battery? A redox flow battery (RFB) consists of three main spatially separate components: a cell stack, a positive electrolyte (shortened: posolyte) reservoir and a

Get a quote

Insights into all-vanadium redox flow battery: A case study on

This work reports a systematic assessment of operating conditions (charge/discharge current density and electrolyte flow rate) and battery components (electrode

Get a quote

Guess what you want to know

-

Netherlands liquid flow battery

Netherlands liquid flow battery

-

All-vanadium redox flow battery market share

All-vanadium redox flow battery market share

-

Vanadium flow battery energy storage trends

Vanadium flow battery energy storage trends

-

Zinc flow battery

Zinc flow battery

-

Semi-solid lithium flow battery

Semi-solid lithium flow battery

-

Angola Flow Battery Company

Angola Flow Battery Company

-

South Sudan 5G Communication Base Station Flow Battery Construction Project

South Sudan 5G Communication Base Station Flow Battery Construction Project

-

Uzbekistan vanadium flow battery project

Uzbekistan vanadium flow battery project

-

1GWh flow battery

1GWh flow battery

-

Guinea communication base station flow battery lightning protection

Guinea communication base station flow battery lightning protection

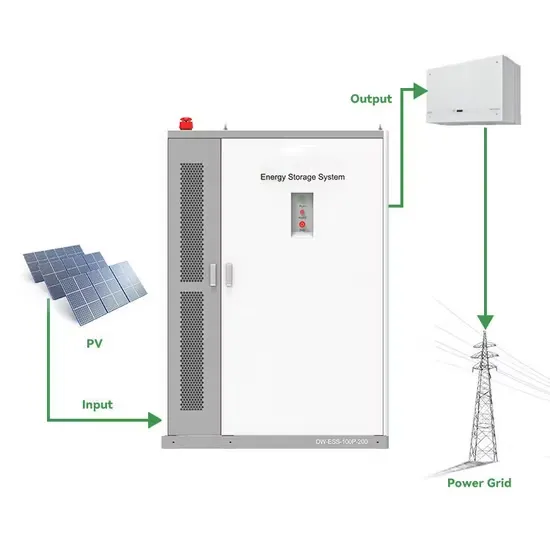

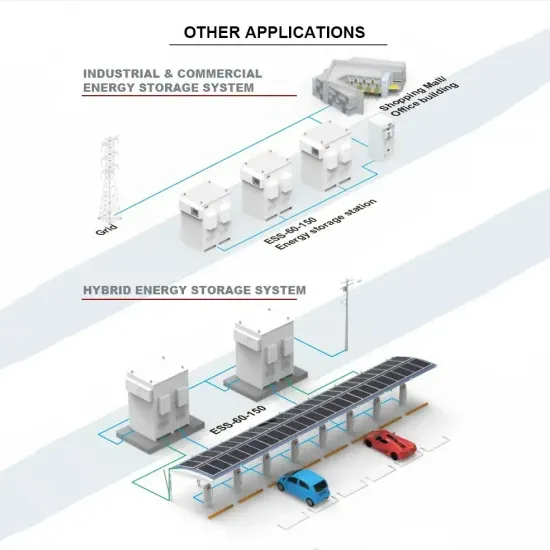

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

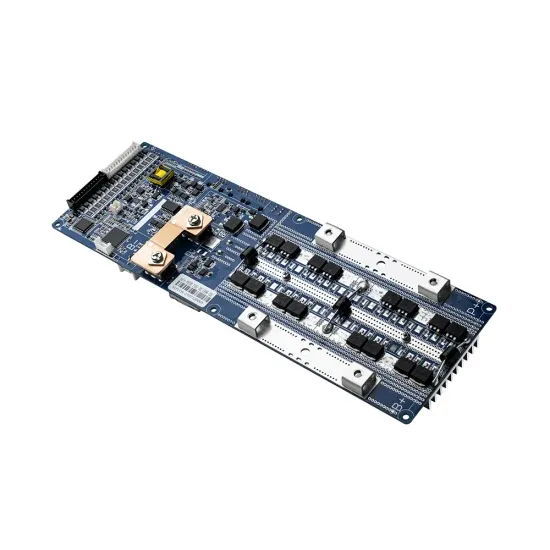

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.