LiFePO4 Battery User Manual

This product specification applies to lithium iron phosphate battery products provided by our company. The product we provide (and which is described in this manual) complies with the

Get a quote

technical parameters of lithium iron phosphate battery pack

The technical parameters introduced in this paper provide an important reference for users in the selection and use of lithium iron phosphate battery pack, help to make more appropriate

Get a quote

Paper Number

This challenge is addressed using a layered approach to break the parameter estimation problem into smaller tasks. The size of each estimation task is reduced to a small subset of data and

Get a quote

Thermal characterization of 18650 lithium iron phosphate cell for

Accurate measurement of heat generation and thermal characterization of lithium-ion batteries is crucial for the design and development of efficient battery thermal management

Get a quote

Technical performance and characteristics of lithium iron phosphate

(1) Technical performance parameters The main technical performance parameters of a typical lithium iron phosphate (LiFePO4) battery for EV and PHEV made by a company

Get a quote

Analysis of the thermal behavior of a LiFePO4 battery

This paper presents theory, experiments and numerical modeling results for the electrothermal analysis of Lithium Iron Phosphate (LiFePO4)

Get a quote

Lithium Iron Phosphate Battery Packs: A Comprehensive Overview

Lithium iron phosphate battery has a series of unique advantages such as high working voltage, high energy density, long cycle life, green environmental protection, etc., and

Get a quote

How to Choose Lithium Battery Solutions: Expert Guide for

The type of lithium battery required for industrial applications is determined by the specific requirements of the equipment being powered: device voltage, load-current, capacity

Get a quote

How To Charge Lithium Iron Phosphate (LiFePO4)

A complete guide on how to charge lithium iron phosphate (LiFePO4) batteries. Learn about the charging of a lithium battery from Power Sonic

Get a quote

Lithium Iron Phosphate Battery Packs: A

Lithium iron phosphate battery has a series of unique advantages such as high working voltage, high energy density, long cycle life, green

Get a quote

Experimental Thermal Analysis of Prismatic Lithium Iron Phosphate

Characterizing the thermal parameters of a lithium-ion battery is an important step for estimating the temperature distribution of battery cell modules. In this study, an

Get a quote

The Ultimate Guide to Optimal Charging Parameters for LiFePO4

Understanding these parameters is essential for maximizing battery life and ensuring efficient operation across various applications. This guide provides an in-depth

Get a quote

Technical performance and characteristics of lithium iron

(1) Technical performance parameters The main technical performance parameters of a typical lithium iron phosphate (LiFePO4) battery for EV and PHEV made by a company

Get a quote

Lithium Iron Phosphate (LiFePO4) Battery

Lighter Weight: About 40% of the weight of a comparable lead acid battery. A ''drop in'' replacement for lead acid batteries. Higher Power: Delivers twice power of lead acid battery,

Get a quote

Understanding LiFePO4 Batteries: Technical

These cells use lithium iron phosphate as the cathode and graphite carbon as the anode. Available in cylindrical, prismatic, or pouch shapes,

Get a quote

Lithium Iron Phosphate Battery Electro-Thermal Analysis for

In this work, the electrical and thermal behavior of the 18650 Lithium Iron Phosphate cell is analyzed using a lumped thermal model in conjunction with an empirical equation that

Get a quote

Failure analysis of lithium iron phosphate batteries

This study investigated the influence of various factors on the safety performance of lithium iron phosphate (LFP) batteries by examining the

Get a quote

Explore LFP Battery Raw Material: LFP Cathode Material

Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing cost, good cycle performance,

Get a quote

Characteristic research on lithium iron phosphate battery of

In this paper, it is the research topic focus on the electrical characteristics analysis of lithium phosphate iron (LiFePO4) batteries pack of power type.

Get a quote

Life-cycle parameter identification method of an electrochemical

An electrochemical model can accurately describe both internal and external characteristics of lithium-ion batteries. However, when the model is adopted for a battery pack,

Get a quote

How to Calculate the Capacity and Voltage of

When designing a battery system using LiFePO4 (Lithium Iron Phosphate) battery, one of the most critical steps is determining the right voltage and

Get a quote

How to Calculate the Capacity and Voltage of LiFePO4 Battery

When designing a battery system using LiFePO4 (Lithium Iron Phosphate) battery, one of the most critical steps is determining the right voltage and capacity to meet your specific

Get a quote

Thermal accumulation characteristics of lithium iron phosphate

Pulse discharge experiments are carried out. The temperature rise characteristics of LIB cells and packs were simulated. The effects of different discharge multipliers, ambient temperatures and

Get a quote

Understanding LiFePO4 Batteries: Technical Specifications and

These cells use lithium iron phosphate as the cathode and graphite carbon as the anode. Available in cylindrical, prismatic, or pouch shapes, these form factors cater to various

Get a quote

Types of LiFePO4 Battery Cells: Cylindrical, Prismatic,

Types of LiFePO4 Battery Cells: Cylindrical, Prismatic, and Pouch Lithium iron phosphate (LiFePO4) batteries are known for their high safety, long cycle life,

Get a quote

Battery Pack Designer''s Guide: From Beginner to Pro [With

Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded

Get a quote

LiFePO4 Battery BMS: 25 Key Parameters for Smart

The LiFePO4 Battery BMS (Battery Management System) is the brain behind lithium iron phosphate battery packs, ensuring safety, efficiency, and

Get a quote

6 FAQs about [Specific parameters of lithium iron phosphate battery pack]

What is a lithium iron phosphate LiFePO4 battery?

It’s the basic unit of a LiFePO4 battery with specifications like nominal voltage around 3.2V and cycle life exceeding 2,000 cycles. Where can you find lithium iron phosphate LiFePO4 batteries for sale?

What are lithium iron phosphate batteries?

In the current energy industry, lithium iron phosphate batteries are becoming more and more popular. These Li-ion cells boast remarkable efficiency, state-of-the-art technology and many other advantages that have been proven to deliver unprecedented power levels for applications.

What temperature does a lithium iron phosphate battery reach?

Although it does not reach the critical thermal runaway temperature of a lithium iron phosphate battery (approximately 80 °C), it is close to the battery's safety boundary of 60 °C. Compared with the 60C discharge condition, the temperature rise trend of 40C and 20C is more moderate.

Are lithium iron phosphate batteries a good choice for electromagnetic launch energy storage?

Lithium iron phosphate batteries are considered to be the ideal choice for electromagnetic launch energy storage systems due to their high technological maturity, stable material structure, and excellent large multiplier discharge performance.

What is a lithium iron phosphate battery energy storage system?

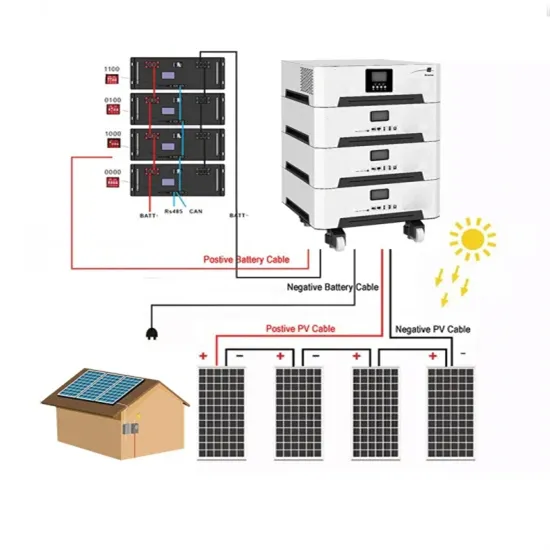

The lithium iron phosphate battery energy storage system consists of a lithium iron phosphate battery pack, a battery management system (Battery Management System, BMS), a converter device (rectifier, inverter), a central monitoring system, and a transformer.

What are the advantages of lithium iron phosphate battery?

Lithium iron phosphate battery has a series of unique advantages such as high working voltage, high energy density, long cycle life, green environmental protection, etc., and supports stepless expansion, and can store large-scale electric energy after forming an energy storage system.

Guess what you want to know

-

Lithium iron phosphate battery pack life

Lithium iron phosphate battery pack life

-

Waterproof lithium iron phosphate battery pack

Waterproof lithium iron phosphate battery pack

-

Lithium iron phosphate battery pack requires balanced voltage

Lithium iron phosphate battery pack requires balanced voltage

-

Island lithium iron phosphate battery pack

Island lithium iron phosphate battery pack

-

48v 100ah lithium iron phosphate battery pack

48v 100ah lithium iron phosphate battery pack

-

Home lithium iron phosphate battery pack

Home lithium iron phosphate battery pack

-

Lithium iron phosphate battery pack management

Lithium iron phosphate battery pack management

-

Tonga lithium iron phosphate battery pack manufacturer

Tonga lithium iron phosphate battery pack manufacturer

-

New Zealand lithium iron phosphate battery pack

New Zealand lithium iron phosphate battery pack

-

50A lithium iron phosphate battery pack

50A lithium iron phosphate battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.