Battery production equipment and services

Battery excellence for all manufacturing processes The increasing demand for clean energy is driving substantial growth in the battery industry. The advanced technology offered by Dürr in

Get a quote

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

Get a quote

Utah-based company aims at solutions for energy autonomy –

An American Fork-based company called Lion Energy is a manufacturer of silent and eco-friendly energy storage solutions and announced Tuesday it is pursuing a cutting

Get a quote

Lithium Battery Charging & Storage Cabinets

Lithium Battery Charging & Storage Cabinets Multifile''s Lithium Battery Charging cabinets are available in both a 20 and 8 station version. The cabinets have been designed with a hot wall

Get a quote

Battery Manufacturing Automation From Bosch Rexroth

This study explores how Bosch Rexroth helped ATS Industrial Automation, Inc. with the design and production of grid storage batteries, all while focusing on

Get a quote

Battery assembly solution

Take your battery assembly operations to the next level with JOT Automation. Whether it''s battery module assembly, battery pack assembly, or fully automated, end-of-line battery assembly,

Get a quote

Automation in battery production

From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery production systems and supplies

Get a quote

Battery manufacturing | Beckhoff Worldwide

Our control technology enables end-to-end automation of all processes in battery manufacturing: from electrode production to module and pack assembly. PC-based control offers advantages

Get a quote

Advanced New Energy Lithium Battery PACK Automated Assembly Production

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge technology through the following

Get a quote

Microvast

Microvast produces innovative and reliable lithium-ion batteries with advanced technologies. With nearly two decades of experience in battery development, we''re accelerating the adoption of

Get a quote

Advanced New Energy Lithium Battery PACK

This state-of-the-art production line achieves seamless automated battery pack production. Spanning an impressive 16 meters, it integrates cutting-edge

Get a quote

HEXUP_A Provider of Battery Swap Cabinets and Battery Swap Stations

HEXUP specializes in providing battery swap stations/cabinets and swapper solutions for electric scooters, ensuring safe charging and convenient lithium battery exchanges. Discover our

Get a quote

Battery Production | Lithium-ion & EV Battery Manufacturing

We also offer battery manufacturing machines to enhance the production and assembly of stationary energy storage solutions, mobile devices, wind turbines, and solar panels.

Get a quote

Lithium Battery Charging Cabinet Market Size & Forecast

Global Lithium Battery Charging Cabinet Market Drivers and Trends The market drivers for the Lithium Battery Charging Cabinet Market can be influenced by various factors. These may

Get a quote

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

Get a quote

EOL testing (Modules & Packs)

Battery End-Of-Line (EOL) Tester One-stop solution for testing lithium battery modules and packs Digatron - an innovator within the battery industry with

Get a quote

Customized Lithium-Ion Battery Storage Cabinets

Rely on Wesgar to produce first-class battery enclosures and take care of your unique needs. Our quality custom lithium-ion battery storage cabinets are

Get a quote

Battery Production Automation

PAR Systems can help you create effective automation systems at any step of your battery production. We provide customized solutions designed for your manufacturing needs.

Get a quote

Lithium-ion Battery Charging & Storage Cabinets

AUD $5,768.40 Lithium-ion Battery Charging & Storage Cabinets 30L – Lithium-ion Battery Charging & Storage Cabinet AUD $9,941.00 Lithium-ion Battery Charging & Storage Cabinets

Get a quote

Battery Manufacturing Automation From Bosch Rexroth

This study explores how Bosch Rexroth helped ATS Industrial Automation, Inc. with the design and production of grid storage batteries, all while focusing on developing a customized

Get a quote

Bringing Battery Manufacturing Back to America

For more information and to explore our fully automated battery pack assembly lines, contact us at Lithium Battery Company or visit our South Tampa facility. Together, we''re

Get a quote

6 FAQs about [Lithium battery station cabinet automation production company]

What is a lithium-ion battery?

Lithium-ion battery solutions for transportation, heavy equipment, and energy storage. Forward Thinking. Microvast produces innovative and reliable lithium-ion batteries with advanced technologies.

How are lithium-ion cells assembled?

In this process step, lithium-ion cells are assembled into modules and connected in series or in parallel. KUKA supplies the turnkey system and keeps an eye on everything: In addition to optimal handling and welding solutions, adhesive bonding, pressing and electrical and thermal contacting are relevant key processes here.

Are low-cost lithium-ion battery cells the key to mass electromobility?

Low-cost lithium-ion battery cells (LIB) are the key to mass electromobility, although the manufacturing process has always been a cost driver – until now. Researchers at TU Berlin are using continuous Z-folding to replace the traditional pick-and-place movements that have been used so far, thereby accelerating battery cell production.

How KUKA robots are used in the production of lithium-ion battery cells?

In the production of lithium-ion battery cells, special high-precision machines are used for individual production steps. KUKA robots can take over certain key processes such as stacking, loading and unloading, or formation and aging of cells.

Why do we need automation in battery production?

Demand for lithium-ion batteries is booming. From smartphones and tablets to e-cars: nothing runs without batteries. Accordingly, the required quantities in battery production are increasing rapidly. The solution lies in automation. This is because the manufacture of batteries is technically demanding and requires high safety standards.

How can a PC-based automation platform improve battery cell winding efficiency?

Our approach involves the use of a central PC-based automation platform to achieve maximum process efficiency in battery cell winding, as this allows vision systems, motion tasks, and communication to I/Os to all be controlled with a high level of synchronicity. It also enables precise winding accuracy while maintaining high output.

Guess what you want to know

-

Timor-Leste lithium battery station cabinet manufacturing company

Timor-Leste lithium battery station cabinet manufacturing company

-

Ethiopia lithium battery station cabinet production plant

Ethiopia lithium battery station cabinet production plant

-

Cote d Ivoire lithium battery station cabinet production integrated system

Cote d Ivoire lithium battery station cabinet production integrated system

-

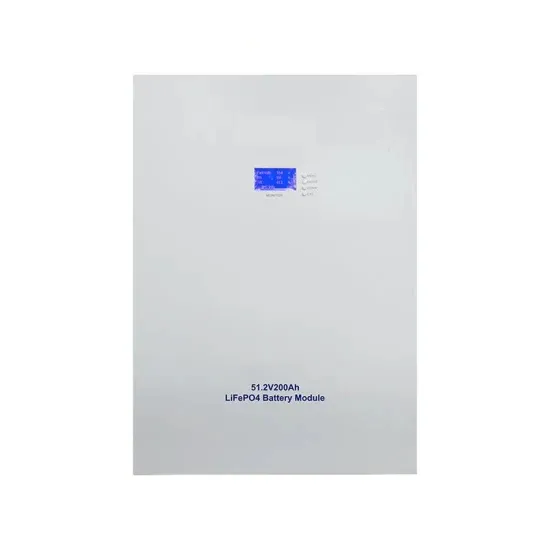

Eight-string lithium iron phosphate battery station cabinet

Eight-string lithium iron phosphate battery station cabinet

-

Lithium battery energy storage power station production

Lithium battery energy storage power station production

-

Communication network cabinet base station power lithium battery

Communication network cabinet base station power lithium battery

-

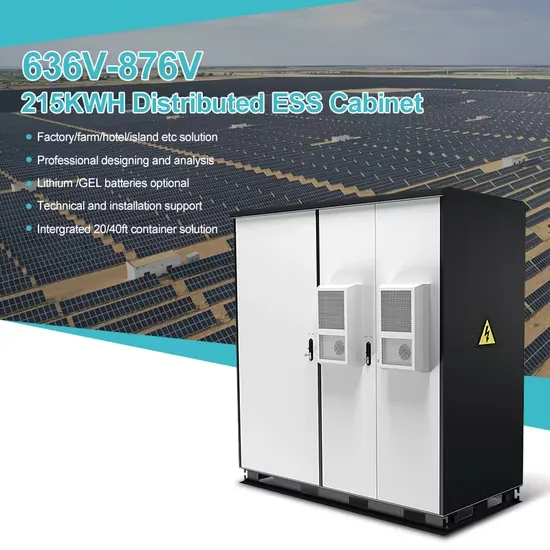

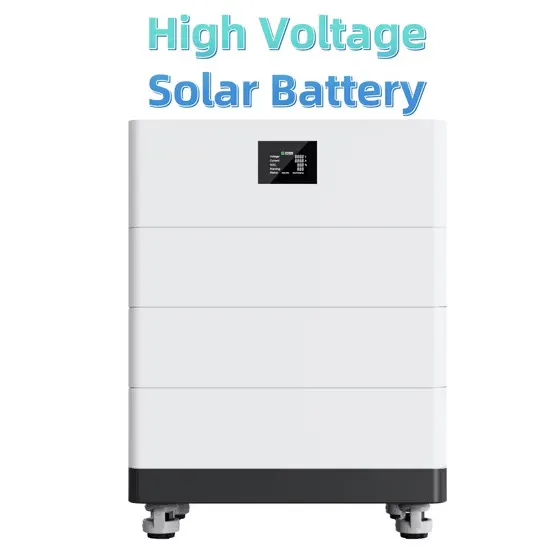

High-power solar lithium battery station cabinet

High-power solar lithium battery station cabinet

-

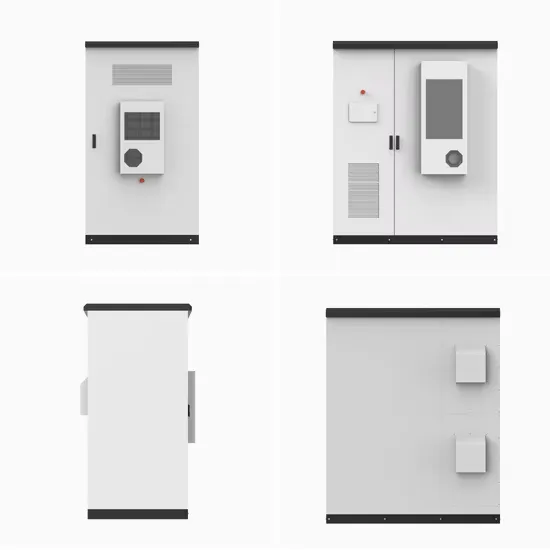

Battery cabinet production process base station

Battery cabinet production process base station

-

Calculation of current and voltage of lithium battery station cabinet

Calculation of current and voltage of lithium battery station cabinet

-

Photovoltaic communication lithium battery station cabinet base station

Photovoltaic communication lithium battery station cabinet base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.