Ultimate Guide to Solar Panel Voltage

However, the output voltage is one of the most critical parameters to help you select the right-size solar power system for your home. Read Jackery''s guide, where we will walk you

Get a quote

Temperature Effects on PV Modules | SunWize | Power

Temperature Effects on PV Modules Understanding Temperature Effects on Crystalline PV Modules While the output current from a Photovoltaic (PV) Module is directly related to the

Get a quote

Understanding Solar Photovoltaic System Performance

This report presents a performance analysis of 75 solar photovoltaic (PV) systems installed at federal sites, conducted by the Federal Energy Management Program (FEMP) with support

Get a quote

Power rating and qualification of bifacial PV modules

The most important reference in setting the price of PV modules is still the power rating under standard test conditions (STC), defined as follows: a device temperature of 25oC, and an

Get a quote

Decoding Solar Panel Output: Voltages, Acronyms, and Jargon

The temperature coefficient of a solar panel is the value represents the change in voltage based on temperature. Generally, it is used to calculate Cold Temp/Higher Voltage situations for

Get a quote

Temperature Coefficient of a Photovoltaic Cell

The temperature coefficient of a particular pv panel or module is not just limited to its open-circuit voltage V OC, but can also be used to translate

Get a quote

Photovoltaic (PV)

Parameters for PV cells are measured under specified standard test conditions (STC). STC is generally taken as 1000 W/m 2, 25 °C and 1.5 AM (air mass). The maximum

Get a quote

PV array temperature correction table (NEC 2017)

There are calculators like this one made by @upnorthandpersonal which help you calculate PV array voltage and power for low temperatures

Get a quote

How to Calculate a PV Module''s Voltage (Voc) for Different

When designing a system, it is important to use the PV module''s Temperature Coefficient to calculate the gains (or losses) in voltage due to local ambient temperature changes. This will

Get a quote

Study of Temperature Coefficients for Parameters of

The temperature is one of the most important factors which affect the performance of the photovoltaic cells and panels along with the irradiance.

Get a quote

Standard Test Conditions (STC) for Solar Panels

The 3 standard test conditions for solar panels are: Cell temperature: 25°C (77°F) Solar irradiance: 1000W/m 2 (1kW/m 2) Air mass

Get a quote

Photovoltaic panel voltage and temperature relationship table

The voltage output is greater at the colder temperature. The effect of temperature can be clearly displayed by a PV panel I-V (current vs. voltage) curve. I-V curves show the different

Get a quote

Temperature Coefficient in Photovoltaic

All PV modules have a temperature coefficient. As a general rule of thumb, as the solar panel temperature rises, its power output will decrease. In

Get a quote

Solar Panel Voltage Calculator

The percentage increase of the maximum voltage of each solar panel estimates how much the open circuit voltage is expected to shoot up. We can estimate its value by

Get a quote

Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV

The operating temperature plays a key role in the photovoltaic conversion process. Both the electrical efficiency and the power output of a photovoltaic (PV) module depend

Get a quote

Photonik | String Voltage Calculator

The amount of voltage (Voc) change is calculated based on the ambient temperature and the solar panel''s "Temperature coefficient of Voc", which is the voltage difference for every degree

Get a quote

Solar Panel Datasheet Specifications Explained

The article covers the key specifications of solar panels, including power output, efficiency, voltage, current, and temperature coefficient, as presented in solar panel datasheets, and

Get a quote

Temperature Coefficient of a Photovoltaic Cell

The temperature coefficient of a particular pv panel or module is not just limited to its open-circuit voltage V OC, but can also be used to translate current and power ratings from

Get a quote

Understanding NMOT In Solar: NMOT vs STC vs

Technician measuring the solar panel temperature and the resulting efficiency drop (at higher temperatures). This decreases the real power rating (Pmax). In

Get a quote

How to Calculate a PV Module''s Voltage (Voc) for

When designing a system, it is important to use the PV module''s Temperature Coefficient to calculate the gains (or losses) in voltage due to local ambient

Get a quote

Decoding Solar Panel Output: Voltages, Acronyms,

The temperature coefficient of a solar panel is the value represents the change in voltage based on temperature. Generally, it is used to calculate Cold

Get a quote

Solar Panel Datasheet Specifications Explained

The article covers the key specifications of solar panels, including power output, efficiency, voltage, current, and temperature coefficient, as presented in solar

Get a quote

Evaluation of the bifaciality coefficient of bifacial photovoltaic

For such purpose, an outdoor campaign was performed to experimentally measure the maximum power bifaciality coefficient of two modified bifacial modules that resemble a rear

Get a quote

Solar panel maximum voltage calculator

The voltage that solar panels work at depends on the cell temperature. The higher the temperature the lower the voltage the solar panel will produce and vise versa. The voltage

Get a quote

Solar Panel Maximum Voltage Calculator

Calculate the maximum voltage increase percentage for each solar panel by multiplying the maximum temperature differential by the panel''s temperature coefficient of Voc.

Get a quote

Guess what you want to know

-

550w photovoltaic panel installed output voltage

550w photovoltaic panel installed output voltage

-

Photovoltaic panel dual voltage output

Photovoltaic panel dual voltage output

-

What is the output voltage of a 295w photovoltaic panel

What is the output voltage of a 295w photovoltaic panel

-

Photovoltaic panel with battery voltage

Photovoltaic panel with battery voltage

-

Does the photovoltaic panel have voltage at night

Does the photovoltaic panel have voltage at night

-

Solar photovoltaic panel 6V voltage output 3V is too low

Solar photovoltaic panel 6V voltage output 3V is too low

-

Photovoltaic panel current and voltage parameters

Photovoltaic panel current and voltage parameters

-

Photovoltaic solar panel voltage

Photovoltaic solar panel voltage

-

Photovoltaic panel voltage is low

Photovoltaic panel voltage is low

-

Is the output voltage of the photovoltaic panel stable

Is the output voltage of the photovoltaic panel stable

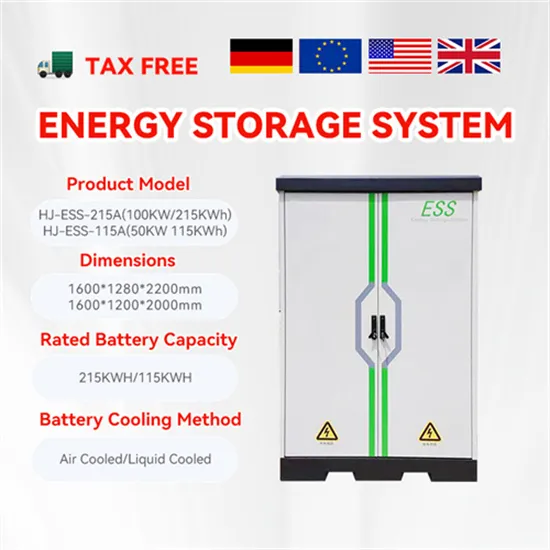

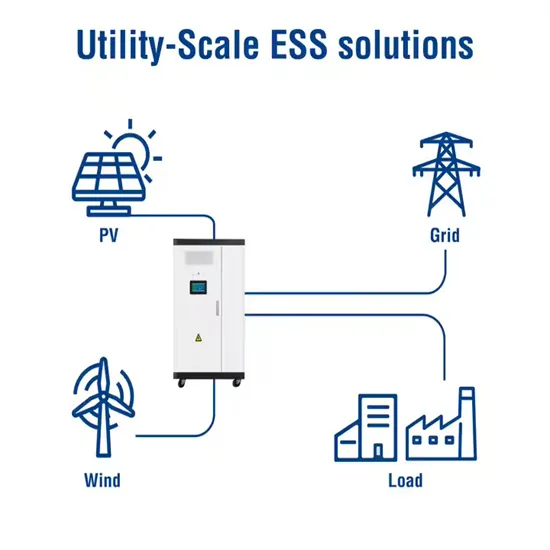

Industrial & Commercial Energy Storage Market Growth

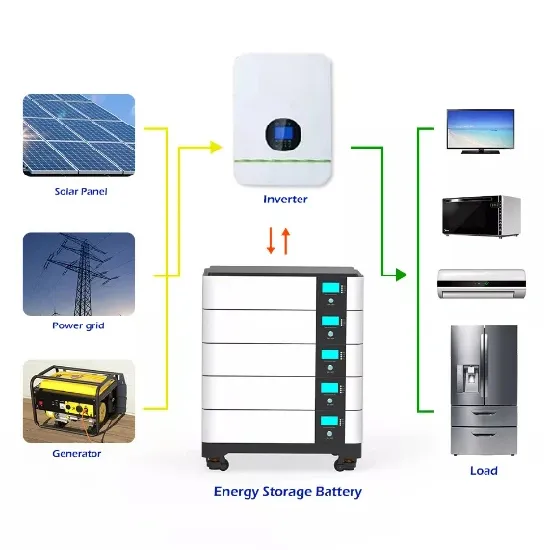

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

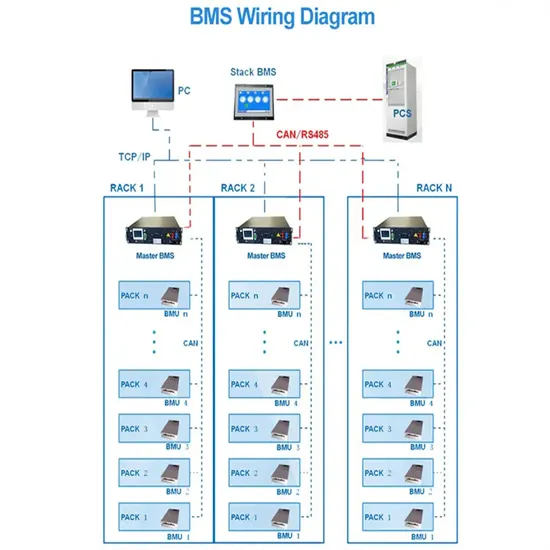

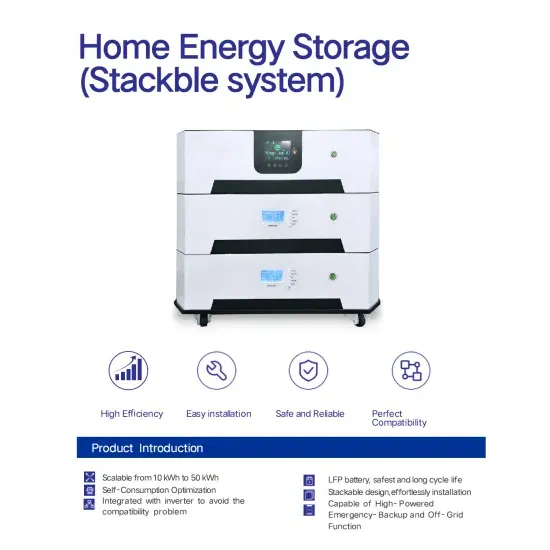

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.