ENERGY STORAGE TECH STARTUPS IN MOSCOW RUSSIA

What is a containerized energy storage system? NEXTG POWER''s Containerized Energy Storage System is a complete, self-contained battery solution for a large-scale energy storage.

Get a quote

Study on uniform distribution of liquid cooling pipeline in container

Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Get a quote

The HBD-A Series from MPMC is an all-in-one, liquid-cooled

1 day ago· The HBD-A Series from MPMC is an all-in-one, liquid-cooled battery energy storage system, covering 100kW–1000kW with capacities from 241.2kWh–2090kWh. Applications: 🔹Self-consumption optimization – maximize solar energy utilization 🔹Peak shaving & load shifting – reduce

Get a quote

InnoChill''s Liquid Cooling Solution: Revolutionizing

Discover how InnoChill''s liquid cooling solution is transforming energy storage systems with superior heat dissipation, improved battery life,

Get a quote

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Get a quote

Air Cooling vs. Liquid Cooling: Why Liquid Cooling is

With its superior thermal performance, enhanced energy efficiency, and improved battery longevity, liquid cooling is rapidly becoming the

Get a quote

How liquid-cooled technology unlocks the potential of energy storage

There are numerous causes of thermal runaway, including internal cell defects, faulty battery management systems, and environmental contamination. Liquid-cooled battery energy storage

Get a quote

110Kw 233Kwh Liquid Cooling Outdoor Cabinets energy storage

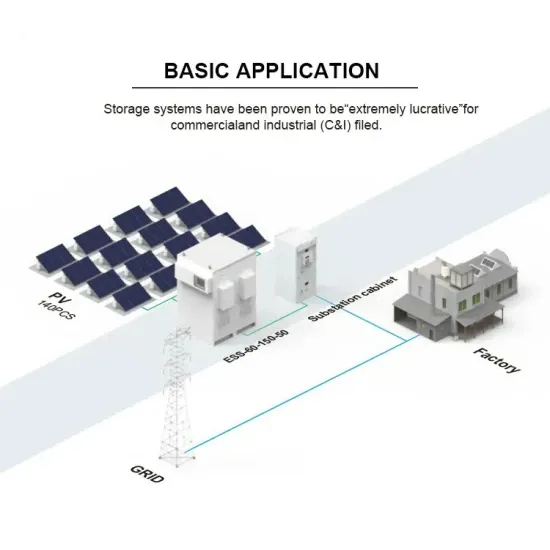

The 233kWh Liquid Cooling Outdoor Cabinets medium-sized energy storage system is an energy storage product designed for industrial and commercial applications. It can be directly

Get a quote

How liquid-cooled technology unlocks the potential of

There are numerous causes of thermal runaway, including internal cell defects, faulty battery management systems, and environmental contamination. Liquid

Get a quote

Battery Energy Storage Systems: Liquid Cooling vs.

By using liquid cooling, PowerTitan guarantees reliability, operational safety, and higher returns on investment for businesses that rely on

Get a quote

Liquid Cooling Solutions for Energy Storage Systems.

Our innovative liquid cooling solutions offer numerous advantages, including efi cient heat dissipation for longer battery life, even temperature distribution for optimal performance and

Get a quote

CONTAINERIZED LIQUID COOLING ENERGY STORAGE SYSTEM

The containerized liquid cooling energy storage system combines containerized energy storage with liquid cooling technology, achieving the perfect integration of efficient

Get a quote

Liquid-Cooled Battery Energy Storage System

High-power battery energy storage systems (BESS) are often equipped with liquid-cooling systems to remove the heat generated by the batteries during

Get a quote

High-uniformity liquid-cooling network designing approach for energy

In this work, an approach for rapid and efficient design of the liquid cooling system for the stations was proposed.

Get a quote

ENERGY STORAGE TECH STARTUPS IN MOSCOW RUSSIA

This system is currently the liquid-cooled energy storage system with the highest volume specific capacity in the world. A standard 20-foot container can accommodate 5MWh, which reduces

Get a quote

A review of battery thermal management systems using liquid cooling

Moreover, the research status and advantages of the combination of PCM and liquid cooling BTMS are introduced. In addition to PCM and liquid cooling, the BTMS operation

Get a quote

373kWh Liquid Cooled Energy Storage System

The MEGATRONS 373kWh Battery Energy Storage Solution is an ideal solution for medium to large scale energy storage projects. Utilizing Tier 1 LFP battery cells, each battery cabinet is

Get a quote

Russian liquid-cooled energy storage lithium battery pack model

This study proposes three distinct channel liquid cooling systems for square battery modules, and compares and analyzes their heat dissipation performance to ensure

Get a quote

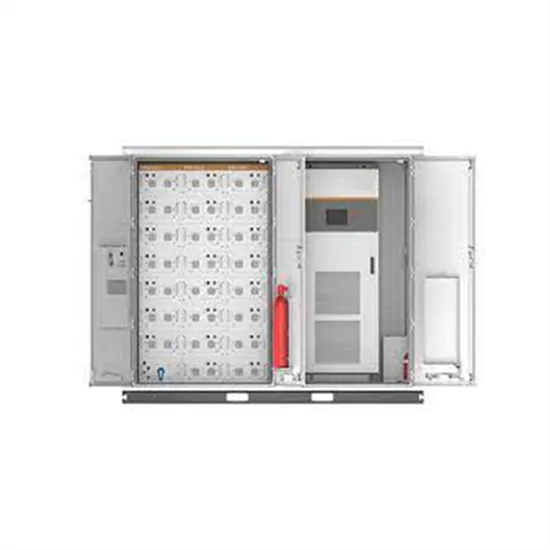

Liquid-Cooled Energy Storage System Architecture

The liquid-cooled energy storage system integrates the energy storage converter, high-voltage control box, water cooling system, fire safety system, and 8 liquid

Get a quote

CATL Cell Liquid Cooling Battery Energy Storage System Series

The liquid-cooled BESS—PKNERGY next-generation commercial energy storage system in collaboration with CATL—features an advanced liquid cooling system for heat dissipation.

Get a quote

High-uniformity liquid-cooling network designing approach for energy

Electrochemical battery energy storage stations have been widely used in power grid systems and other fields. Controlling the temperature of numerous batteries in the energy

Get a quote

Liquid Cooling Energy Storage System Design: The Future of

Ever wondered how your smartphone battery doesn''t overheat during a 4K video binge? Now imagine scaling that cooling magic to power entire cities. That''s exactly what

Get a quote

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring

Get a quote

Unleashing Efficiency: Liquid Cooling in Energy Storage Systems

This comprehensive exploration delves into the intricacies of liquid cooling technology within energy storage systems, unveiling its applications, advantages, and the

Get a quote

Unleashing Efficiency: Liquid Cooling in Energy

This comprehensive exploration delves into the intricacies of liquid cooling technology within energy storage systems, unveiling its applications,

Get a quote

Liquid-Cooled Energy Storage System Architecture and BMS

The liquid-cooled energy storage system integrates the energy storage converter, high-voltage control box, water cooling system, fire safety system, and 8 liquid-cooled battery packs into

Get a quote

6 FAQs about [Russian energy storage liquid cooling system]

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

Are liquid cooled battery energy storage systems better than air cooled?

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. “If you have a thermal runaway of a cell, you’ve got this massive heat sink for the energy be sucked away into. The liquid is an extra layer of protection,” Bradshaw says.

What is the difference between air cooled and liquid cooled energy storage?

The implications of technology choice are particularly stark when comparing traditional air-cooled energy storage systems and liquid-cooled alternatives, such as the PowerTitan series of products made by Sungrow Power Supply Company. Among the most immediately obvious differences between the two storage technologies is container size.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Guess what you want to know

-

Industrial and commercial energy storage liquid cooling configuration

Industrial and commercial energy storage liquid cooling configuration

-

Immersed Energy Storage Liquid Cooling System

Immersed Energy Storage Liquid Cooling System

-

Flywheel energy storage 5MWH liquid cooling installation

Flywheel energy storage 5MWH liquid cooling installation

-

Liquid Cooling Energy Storage Cabinet Design Standard

Liquid Cooling Energy Storage Cabinet Design Standard

-

215 Liquid Cooling Energy Storage Cabinet Manufacturer

215 Liquid Cooling Energy Storage Cabinet Manufacturer

-

Energy Storage Liquid Cooling Standards

Energy Storage Liquid Cooling Standards

-

Liquid Cooling Energy Storage Container Price in Mozambique

Liquid Cooling Energy Storage Container Price in Mozambique

-

Turkmenistan liquid cooling energy storage container price

Turkmenistan liquid cooling energy storage container price

-

Liquid cooling energy storage box structure

Liquid cooling energy storage box structure

-

Azerbaijan liquid cooling energy storage container price

Azerbaijan liquid cooling energy storage container price

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.