Solar cell

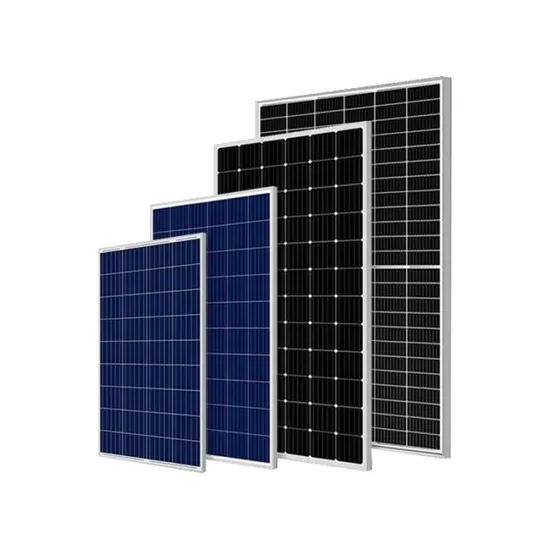

From a solar cell to a PV system. Diagram of the possible components of a photovoltaic system Greencap Energy rooftop solar panels in Worthing, United Kingdom Multiple solar cells in an

Get a quote

How Monocrystalline Solar Cells Work

This article looks in detail at how monocrystalline solar panels work. If you''re looking for a simple explanation of solar photovoltaics, you may

Get a quote

Silicon-Based Technologies for Flexible Photovoltaic

Over the past few decades, silicon-based solar cells have been used in the photovoltaic (PV) industry because of the abundance of silicon

Get a quote

Crystalline Silicon Solar Cell

Mono-crystalline silicon is composed of a homogeneous crystal structure throughout the material produced in the form of wafers sliced from silicon ingots. The device structure of a silicon solar

Get a quote

(PDF) A Review of Solar Photovoltaic Technologies

As per the brief description of the manufacturing process, the complicated manufacturing process of this monocrystalline silicon has greatly

Get a quote

Optimization of monocrystalline silicon photovoltaic module

This study presents a systematic approach to enhance the efficiency of monocrystalline silicon photovoltaic module assembly lines using advanced simulation modeling.

Get a quote

What is the difference between monocrystalline and polycrystalline PV

Monocrystalline silicon photovoltaic modules use high-purity monocrystalline silicon materials, which have higher light conversion efficiency, typically ranging from 15% to 22%, generating

Get a quote

Environmental impact of monocrystalline silicon photovoltaic

Production of polycrystalline silicon, PV cell and PV module are key processes. The key sub-processes of environmental impact in six processes were identified. Optimized

Get a quote

Monocrystalline Solar Panel Efficiency, Construction

Monocrystalline panels perform better in low-light conditions compared to other solar panel types. They are ideal for limited space

Get a quote

Crystalline silicon solar cells: Better than ever

Silicon-based photovoltaics dominate the market. A study now sets a new record efficiency for large-area crystalline silicon solar cells, placing the theoretical efficiency limits

Get a quote

Monocrystalline silicon solar cells applied in photovoltaic system

Photovoltaic module was produced from solar cells with the largest short-circuit current, which were joined in series. Findings: This work presents a conventional technological process by

Get a quote

Development of lightweight and flexible crystalline silicon solar

Solar cells are one of the most sustainable forms of renewable energy. Crystalline silicon (c-Si) solar cell modules hold greater than 90% of the solar cell module market share.

Get a quote

Photovoltaic Cell Generations | Encyclopedia MDPI

First Generation: This category includes photovoltaic cell technologies based on monocrystalline and polycrystalline silicon and gallium arsenide (GaAs).

Get a quote

Comprehensive Guide to Monocrystalline Solar Panel

This article will provide an overview of how monocrystalline solar panels work, their installation requirements, practical applications, and tips for selecting the best solar panel for

Get a quote

Monocrystalline Silicon Solar Cells | PDF | Photovoltaics

The paper discusses the fabrication of monocrystalline silicon solar cells using screen printing technology to create a photovoltaic system. It details the production process, electrical

Get a quote

Monocrystalline silicon: efficiency and manufacturing process

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to

Get a quote

Crystalline Silicon Photovoltaics

Crystalline Silicon Photovoltaics Characteristics of crystalline silicon photovoltaics Crystalline silicon photovoltaics is the most widely used photovoltaic

Get a quote

Environmental impact of monocrystalline silicon photovoltaic modules

Production of polycrystalline silicon, PV cell and PV module are key processes. The key sub-processes of environmental impact in six processes were identified. Optimized

Get a quote

Unlocking the Potential of Monocrystalline Solar

Welcome to the world of monocrystalline solar modules, where efficiency meets innovation. Often heralded as the gold standard in solar technology,

Get a quote

Optimization of monocrystalline silicon photovoltaic module

This study presents a systematic approach to enhance the efficiency of monocrystalline silicon photovoltaic module assembly lines using advanced simulation

Get a quote

Comprehensive Guide to Monocrystalline Solar Panel

This article will provide an overview of how monocrystalline solar panels work, their installation requirements, practical applications, and tips for

Get a quote

Optimization of monocrystalline silicon photovoltaic

This study presents a systematic approach to enhance the efficiency of monocrystalline silicon photovoltaic module assembly lines using

Get a quote

Monocrystalline silicon solar cells applied in photovoltaic system

The module was used to build a demonstration photovoltaic system - traffic light - pedestrian crossing, which shows the practical use of widely available, renewable energy source which is

Get a quote

How Monocrystalline Solar Cells Work

This article looks in detail at how monocrystalline solar panels work. If you''re looking for a simple explanation of solar photovoltaics, you may wish to read the article on how

Get a quote

Monocrystalline Solar Panel Efficiency, Construction & Functionality

Monocrystalline panels perform better in low-light conditions compared to other solar panel types. They are ideal for limited space applications due to their high efficiency and

Get a quote

Efficiency Analysis of Different Photovoltaic Materials

This study presents a comparative efficiency analysis of various photovoltaic materials, including monocrystalline silicon, polycrystalline silicon, thin-film (CdTe and CIGS),

Get a quote

Unlocking the Potential of Monocrystalline Solar Modules: A

Welcome to the world of monocrystalline solar modules, where efficiency meets innovation. Often heralded as the gold standard in solar technology, monocrystalline solar modules offer

Get a quote

Monocrystalline silicon: efficiency and manufacturing

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy,

Get a quote

Solar Cells and Modules

Polycrystalline Silicon Photovoltaic (PV) Cells Polycrystalline or multi crystalline silicon PV cells are made from cast square ingots — large blocks of molten

Get a quote

Guess what you want to know

-

Huawei now has monocrystalline silicon photovoltaic modules

Huawei now has monocrystalline silicon photovoltaic modules

-

Myanmar monocrystalline silicon photovoltaic modules

Myanmar monocrystalline silicon photovoltaic modules

-

Photovoltaic panels monocrystalline silicon double glass

Photovoltaic panels monocrystalline silicon double glass

-

Uruguayan monocrystalline silicon photovoltaic panels

Uruguayan monocrystalline silicon photovoltaic panels

-

700w monocrystalline silicon photovoltaic panel

700w monocrystalline silicon photovoltaic panel

-

Syrian monocrystalline silicon photovoltaic panel specifications

Syrian monocrystalline silicon photovoltaic panel specifications

-

Disadvantages of monocrystalline silicon photovoltaic panels

Disadvantages of monocrystalline silicon photovoltaic panels

-

Price difference of monocrystalline silicon photovoltaic panels of the same specifications

Price difference of monocrystalline silicon photovoltaic panels of the same specifications

-

20w monocrystalline silicon photovoltaic solar panel

20w monocrystalline silicon photovoltaic solar panel

-

Are solar photovoltaic panels considered monocrystalline silicon

Are solar photovoltaic panels considered monocrystalline silicon

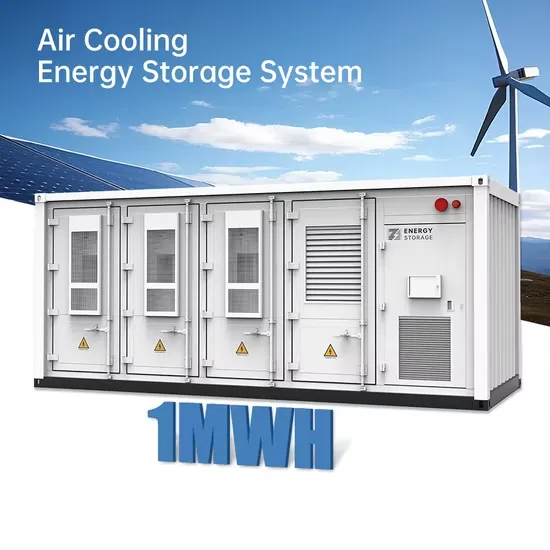

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.