Power rating and qualification of bifacial PV modules

In response to the strong demand for an appropriate power rating method for bifacial PV modules, the international standard IEC 60904-1-2 has been proposed, which describes the test methods...

Get a quote

Standards Procedures for Bifacial Parameters Measurements and

The procedures for the measurement of the current-voltage (I-V) characteristics and bifaciality parameters of bifacial photovoltaic devices are analytically described in the IEC 60904-1-2

Get a quote

IEC 60904-1-2

This part of IEC 60904 describes procedures for the measurement of the current-voltage (I-V) characteristics of bifacial photovoltaic devices in natural or simulated sunlight. It is applicable

Get a quote

Evaluation of the bifaciality coefficient of bifacial photovoltaic

ABSTRACT: Among the parameters that define a bifacial photovoltaic module, the bifaciality coefficients indicate the rear and front side ratio of the most representative IV curve points of a

Get a quote

IEC TS 60904-1-2:2024 Photovoltaic devices

IEC TS 60904-1-2:2024 describes procedures for the measurement of the current-voltage (I-V) characteristics of single junction bifacial photovoltaic devices in natural or simulated sunlight. It

Get a quote

What Defines Bifacial Module Power Generation

Furthermore, the IEC standard also defines "Bifacial Standard Irradiance (BSI)" for assessing bifacial reliability. Here, the module front

Get a quote

Performance analysis and comparison between bifacial and

This paper analyses and compares the performance between a bifacial and a monofacial PV system based on the tests conducted at Heriot-Watt University, UK. The

Get a quote

IEC 61215 Certification Testing, PV specialized

IEC 61215 is the standard which indicates the requirements for the design approval and qualification process and type approval of terrestrial PV modules suitable for long-term

Get a quote

Bifacial PV Characterization and Rating Standards

Through simulation and experiment, we are investigating back-side irradiance conditions that are appropriate for the power rating of bifacial modules. We are

Get a quote

Evaluation of the bifaciality coefficient of bifacial photovoltaic

ABSTRACT Among the parameters that define a bifacial photovoltaic module, the bifaciality coefficients indicate the rear and front side ratio of the most representative IV curve points of a

Get a quote

Understanding Bifacial Photovoltaic''s Potential

Bifacial market needs (~2016) The PV industry is set for rapid uptake of bifacial PV if key barriers are eliminated accurate performance models reliability standards and STC rating of bifacial

Get a quote

IEC 61215-1:2021

This part of IEC 61215 lays down IEC requirements for the design qualification and type approval of terrestrial photovoltaic (PV) modules suitable for long-term operation in general open-air

Get a quote

Comprehensive study on the efficiency of vertical bifacial photovoltaic

The VBPV system, characterized by its vertical orientation and the use of high-efficiency Heterojunction cells, introduces a novel concept diverging from traditional solar

Get a quote

Evaluation of the bifaciality coefficient of bifacial photovoltaic

For such purpose, an outdoor campaign was performed to experimentally measure the maximum power bifaciality coefficient of two modified bifacial modules that resemble a rear

Get a quote

Bifacial PV Characterization and Rating Standards

Through simulation and experiment, we are investigating back-side irradiance conditions that are appropriate for the power rating of bifacial modules. We are also field testing proposed

Get a quote

Performance characteristics of bifacial PV modules and

Validation of output power specification is part of IEC 61215 product qualification testing. Production tolerances of rear performance are typically higher compared to front side. How to

Get a quote

What Defines Bifacial Module Power Generation Performance?

Furthermore, the IEC standard also defines "Bifacial Standard Irradiance (BSI)" for assessing bifacial reliability. Here, the module front continues to receive 1000W/m², but the

Get a quote

Understanding Bifacial Photovoltaic''s Potential

1-axis tracker validation is underway at NREL and is showing good bifacial annual energy gain of 6.5% and 9% for PERC and Si-HJT, respectively. We are working with industry to update

Get a quote

Complete Guide to Bifacial Solar Panels

Bifacial Solar Panel Performance: Measuring and Maximizing Energy Output Understanding bifacial panel performance requires different metrics than traditional solar

Get a quote

Performance of bifacial PV modules under different operating

These modules collect solar radiation on both front and rear sides, providing gains in electricity production compared to traditional monofacial modules. The market acceptance and quality

Get a quote

Standards Procedures for Bifacial Parameters

The procedures for the measurement of the current-voltage (I-V) characteristics and bifaciality parameters of bifacial photovoltaic devices are analytically

Get a quote

IEC TS 60904-1-2:2024

IEC TS 60904-1-2:2024 describes procedures for the measurement of the current-voltage (I-V) characteristics of single junction bifacial photovoltaic devices in natural or simulated sunlight. It

Get a quote

Analysis of requirements, specifications and regulation of BIPV

The standard defines the basic safety test requirements and additional tests that are a function of the PV module end-use applications. Test categories include general inspection, electrical

Get a quote

What Is Heterojunction Technology (HJT solar) and

Discover how Heterojunction Technology (HJT) is shaping the future of solar PV panels—and why rigorous inspection is crucial for long-term performance and

Get a quote

IEC TS 60904-1-2:2024

The requirements for measurement of I-V characteristics of standard (monofacial) PV devices are covered by IEC 60904-1, whereas this document describes the additional requirements for the

Get a quote

Both sides now: Optimal bifaciality with silicon

This simple approach was taken, whatever the actual parameters determining the bifaciality factor, such as system design (module tilt and elevation above ground, number of modules

Get a quote

6 FAQs about [Photovoltaic module bifaciality standard requirements]

Do bifacial PV modules need a power rating method?

In response to the strong demand for an appropriate power rating method for bifacial PV modules, the international standard IEC 60904-1-2 has been proposed, which describes the test methods and additional requirements for the I–V characterization.

Do bifacial PV modules need to be electrically stabilized?

In accordance with IEC 61215-1,-1-1,-2 standards, PV modules should be electrically stabilized before any further measurement. As bifacial PV devices are mostly PERT, PERC and HJT technology based, issues such as light-induced degradation (LID) exist and should not be neglected.

What are bifacial PV modules?

The global PV industry is experiencing a boom in bifacial PV modules. Coming with extra energy gain from the rear side, bifacial PV modules are finding themselves with versatile and promising application possibilities in many fields, from building-integrated photovoltaics to utility-scale power plants.

What is the power bifaciality coefficient of a photovoltaic module?

In the light of the results obtained, the power bifaciality coefficient of a photovoltaic module, measured experimentally in real operating conditions and translated to STC, matches relatively well the value indicated by the manufacturer in its datasheet.

Are bifacial PV modules better than monofacial solar panels?

Compared with monofacial PV modules, energy yields of around 10% higher (or even more) from bifacial modules in the field have been consistently reported by various parties [2,3]. Such increases in yield can considerably reduce the levelized cost of energy. Bifacial PV technology is not a new concept in the PV community.

Can a solar simulator be used to measure bifacial PV devices?

As described in IEC 60904-1-2, for single-sided illumination measurements of bifacial PV devices, a solar simulator (as defined in IEC 60904-9 ) with adjustable irradiance level has to be used for the I-V characterisation.

Guess what you want to know

-

Malawi standard photovoltaic module prices

Malawi standard photovoltaic module prices

-

Standard photovoltaic module projects include

Standard photovoltaic module projects include

-

Huawei Standard Photovoltaic Module Project

Huawei Standard Photovoltaic Module Project

-

Mexican standard photovoltaic module prices

Mexican standard photovoltaic module prices

-

Vietnam local photovoltaic module prices

Vietnam local photovoltaic module prices

-

Thin-film photovoltaic module subsidies

Thin-film photovoltaic module subsidies

-

What are the requirements for exporting photovoltaic modules

What are the requirements for exporting photovoltaic modules

-

Comoros exports photovoltaic module inverters

Comoros exports photovoltaic module inverters

-

Sao Tome and Principe Huijue Photovoltaic Module Project

Sao Tome and Principe Huijue Photovoltaic Module Project

-

Photovoltaic power station energy storage requirements

Photovoltaic power station energy storage requirements

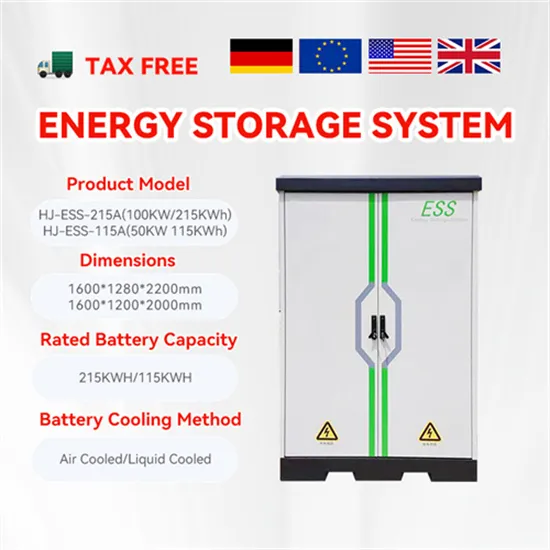

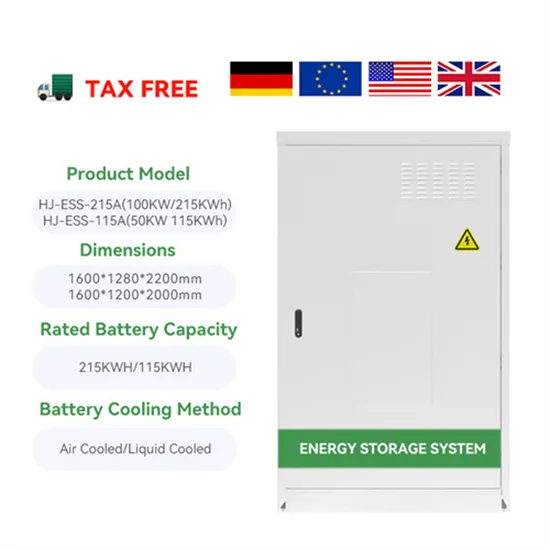

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.