The battery industry has entered a new phase – Analysis

After years of investments, global battery manufacturing capacity reached 3 TWh in 2024, and the next five years could see another tripling of production capacity if all announced

Get a quote

ROHM and Schaeffler Begin Mass Production of SiC-Based High

ROHM and Schaeffler have started mass production of a new high-voltage inverter brick equipped with ROHM''s SiC (silicon carbide) MOSFET bare chips as part of their strategic

Get a quote

Top 18 Solar Inverter Manufacturers in China 2022

In other words, a solar inverter is a crucial part of solar panels, so it''s also crucial that the inverters in your panels are of the greatest quality. And

Get a quote

Q&A: How do inverters and batteries collaborate in

In regard to batteries, SolarEdge built its solution to support high-voltage DC batteries because we believe that this is the most efficient and

Get a quote

Battery Manufacturing Process: Materials, Production & Test

This guide covers the entire process, from material selection to the final product''s assembly and testing. Whether you''re a professional in the field or an enthusiast, this deep

Get a quote

Current and future lithium-ion battery manufacturing

Here in this perspective paper, we introduce state-of-the-art manufacturing technology and analyze the cost, throughput, and energy consumption based on the

Get a quote

The Power Behind Solar Generators: Understanding

Key Takeaways Inverters play a pivotal role in solar generators by converting direct current (DC) into alternating current (AC), which is essential for

Get a quote

A technical review of modern traction inverter systems used in

This article presents a comprehensive review of modern traction inverter systems, their possible control strategies, and various modulation techniques deployed in electric

Get a quote

13+ Best Solar Inverters in South Africa: Beat Load

Key Takeaway: The best solar inverters in South Africa include Sunsynk, Fronius, SolarEdge, Sungrow, SMA, Huawei, GoodWe and Victron Energy, MLT

Get a quote

Growatt opens automated factory in Vietnam to

Growatt has an expansion plan to achieve an annual production capacity of 500,000 units of inverters and 100,000 units of batteries to serve

Get a quote

PRODUCTION OF AN ALL-SOLID-STATE BATTERY CELL

structure and the production technologies used for its manufacturing. This brochure focuses on the production of the all-solid-state battery and provides initial answers to questions about

Get a quote

How To Produce Inverter: A Step-by-Step Guide

This article will explain how to produce inverter and the key components and walk you through the manufacturing process, from design to final assembly.

Get a quote

Solar Inverter Cost Analysis from Manufacturing

The cost of manufacturing solar inverters is shaped by a variety of factors, from the cost of high-quality materials and production efficiency to

Get a quote

Growatt opens automated factory in Vietnam to produce batteries, inverters

Growatt has an expansion plan to achieve an annual production capacity of 500,000 units of inverters and 100,000 units of batteries to serve the growing U.S. market as

Get a quote

How To Start A Lucrative Inverter Battery Production

Inverter battery production and supply business is a lucrative venture in Nigeria and Africa due to the increasing demand for reliable and

Get a quote

SolarEdge Home Hub Three Phase Inverter – Supported

The SolarEdge Home Hub Three Phase Inverter (SExK-RWB48), or "SolarEdge Home Hub Inverter" or "the Inverter", can be used for various applications that enable energy

Get a quote

How To Produce Inverter: A Step-by-Step Guide

This article will explain how to produce inverter and the key components and walk you through the manufacturing process, from design to final assembly.

Get a quote

Top 24 Solar Inverter Manufacturers

The solar inverter manufacturing industry plays a crucial role in the renewable energy sector, focusing on converting solar energy into viable power for

Get a quote

Inverter Battery Manufacturing Technology and Advantages

Inverter battery manufacturing technology has made remarkable strides, and the advantages these batteries offer are extensive. From ensuring uninterrupted power supply and

Get a quote

The Battery Manufacturing Process

Discover the battery manufacturing process in gigafactories. Explore the key phases of production – from active material to validation, as automation tackles high-volume

Get a quote

Inverter Battery Manufacturing Plant Report 2025: Setup Cost

IMARC Group''s report on inverter battery manufacturing plant project provides detailed insights into business plan, setup, cost, layout and requirements.

Get a quote

Battery Manufacturing Process: Materials, Production

This guide covers the entire process, from material selection to the final product''s assembly and testing. Whether you''re a professional in the field

Get a quote

How is the inverter manufactured?

In this article, Junchipower will introduce in detail the entire process of inverter production, from design planning to factory delivery, and gradually analyze the key steps and

Get a quote

Guess what you want to know

-

Can gel batteries be used in inverters

Can gel batteries be used in inverters

-

Can Belgian lithium batteries be used as inverters

Can Belgian lithium batteries be used as inverters

-

Production of energy storage lithium batteries

Production of energy storage lithium batteries

-

12V batteries to power inverters

12V batteries to power inverters

-

Production of industrial frequency sine wave inverters

Production of industrial frequency sine wave inverters

-

Production time of energy storage cabinet batteries

Production time of energy storage cabinet batteries

-

Can industrial frequency inverters use lithium batteries

Can industrial frequency inverters use lithium batteries

-

Do Zambian inverters support lithium batteries

Do Zambian inverters support lithium batteries

-

Where are the batteries for the energy storage cabinet inverters produced

Where are the batteries for the energy storage cabinet inverters produced

-

How to match batteries with solar water pump inverters

How to match batteries with solar water pump inverters

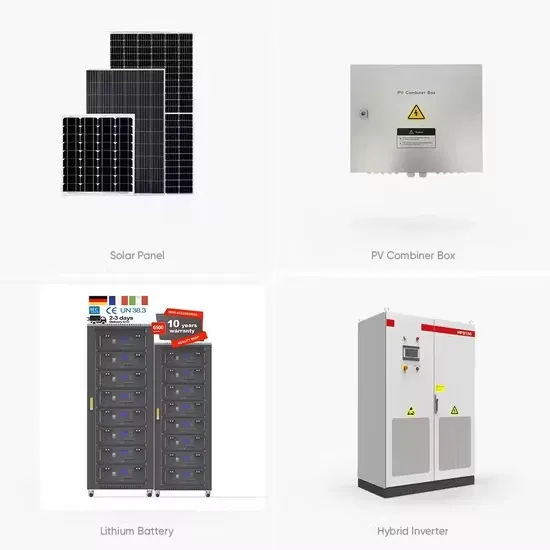

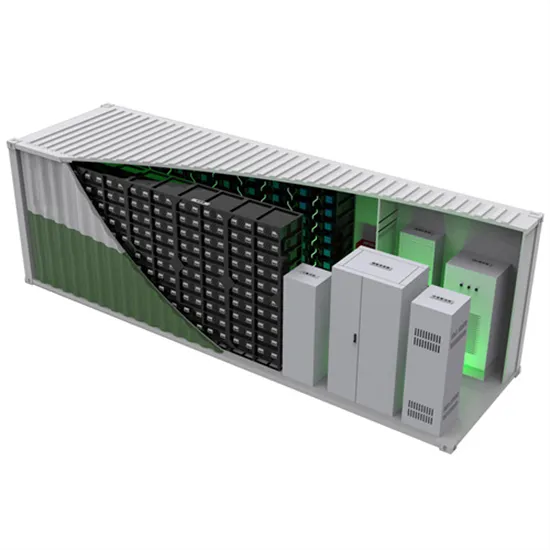

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

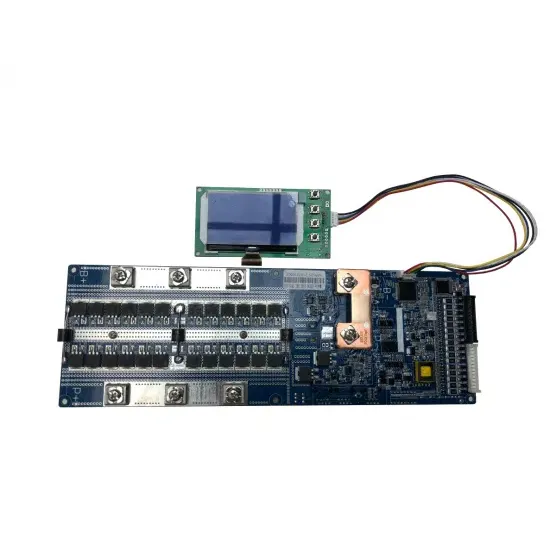

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.