Container Design for Battery Energy Storage System (BESS)

Learn how we optimized design of a battery storage system container to reduce weight, ensure structural integrity, and achieve efficient thermal regulation.

Get a quote

Understanding the Energy Capacity and Applications

Explore how energy capacity and power ratings define BESS container performance. Learn the relationship between power and energy in

Get a quote

Container Energy Storage System: All You Need to Know

The design and engineering of the container in a container energy storage system play a crucial role in ensuring both safety and efficiency. From the choice of materials to the

Get a quote

Unlock the Future of Energy with TLS Battery Energy Storage

In today''s fast-evolving energy landscape, TLS Battery Energy Storage Systems (BESS) are transforming how we harness and manage renewable energy. Whether you''re

Get a quote

Simulation analysis and optimization of containerized energy storage

This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Get a quote

Container Design for Battery Energy Storage System

Learn how we optimized design of a battery storage system container to reduce weight, ensure structural integrity, and achieve efficient thermal regulation.

Get a quote

Container energy storage system commissioning

Containerized energy storage systems encompass all stages from planning, design, construction, and operation to final decommissioning. This process involves not only the technical

Get a quote

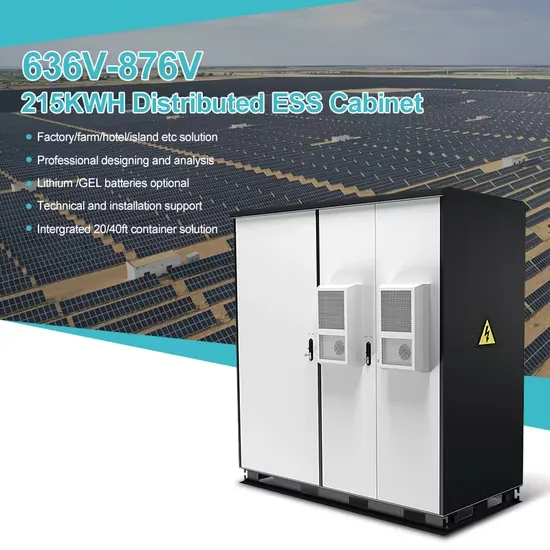

What is the maximum volt of container energy storage?

The maximum voltage of container energy storage varies significantly based on the design, intent of use, and technology applied. 1. Container energy storage systems may

Get a quote

Why 20ft ISO Containers Are Widely Used in Energy

Discover the key advantages of using 20ft ISO containers for battery energy storage systems (BESS), including modularity, transportability,

Get a quote

Energy storage container, BESS container

What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard containers to build

Get a quote

What is the capacity of the energy storage container?

The capacity of an energy storage container primarily depends on its design and application. 1. Energy storage containers can vary significantly in size and utilization, ranging

Get a quote

Conceptual thermal design for 40 ft container type 3.8 MW energy

Search ScienceDirect Sustainable Energy Technologies and Assessments Volume 56, March 2023, 103075 Conceptual thermal design for 40 ft container type 3.8 MW energy

Get a quote

Energy storage containers: an innovative tool in the green energy

The article aims to provide readers with a comprehensive understanding of energy storage container technology to promote its widespread application and promotion in the future

Get a quote

Container Energy Storage System: All You Need to

The design and engineering of the container in a container energy storage system play a crucial role in ensuring both safety and efficiency. From

Get a quote

Energy Storage Container Design Information List: Key

This article breaks down the energy storage container design information list into bite-sized pieces—perfect for engineers, project managers, and clean energy nerds who want

Get a quote

Energy storage on demand: Thermal energy storage

Energy storage materials and applications in terms of electricity and heat storage processes to counteract peak demand-supply inconsistency are hot topics, on which many

Get a quote

Containerized Energy Storage Systems: A Detailed Guide to

This detailed guide will explore the design and benefits of containerized energy storage systems, shedding light on their potential to revolutionize the energy industry.

Get a quote

Park energy storage container layout planning

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Get a quote

Simulation analysis and optimization of containerized energy

This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Get a quote

Container Energy Storage Systems : Structural & Door Design

The overall structural design of the module must comply with current national standards and design specifications. It should integrate practical engineering considerations with the judicious

Get a quote

Key Design Considerations for Energy Storage Containers

The design of energy storage containers involves an integrated approach across material selection, structural integrity, and comprehensive safety measures. Choosing the right

Get a quote

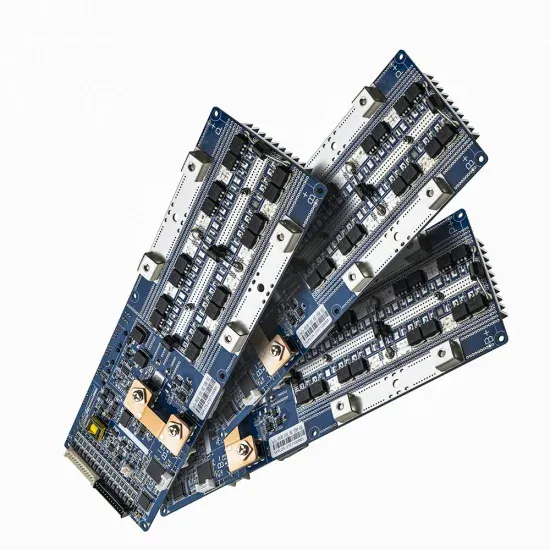

Energy storage container battery module design

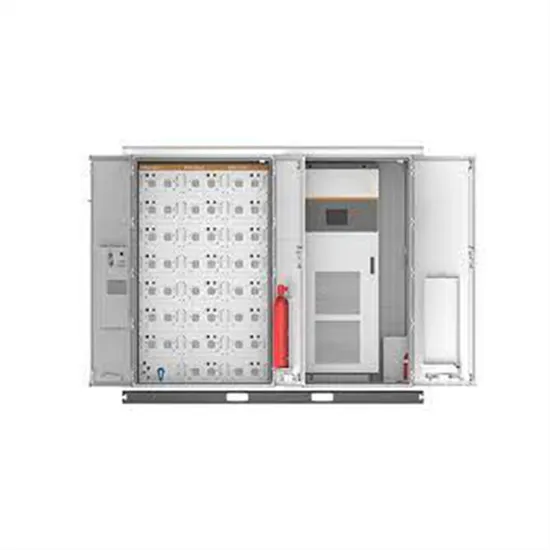

The EnerC+ container is a battery energy storage system (BESS) that has four main components: batteries, battery management systems (BMS), fire suppression systems (FSS), and thermal

Get a quote

A methodical approach for the design of thermal energy storage

Recent research focuses on optimal design of thermal energy storage (TES) systems for various plants and processes, using advanced optimization techniques. There is a

Get a quote

Common specifications and dimensions of energy storage

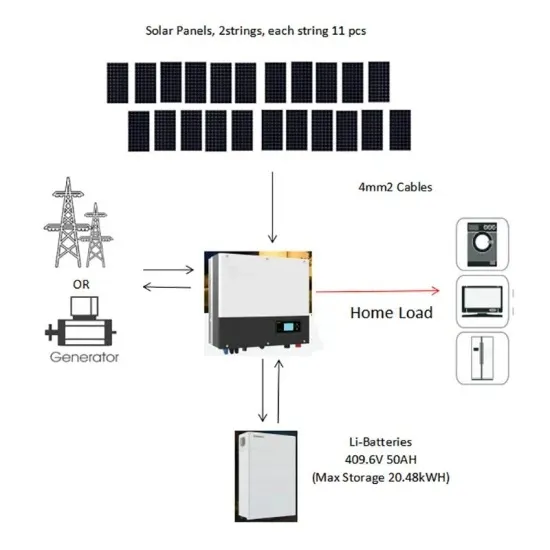

A Battery Energy Storage System (BESS) significantly enhances power system flexibility, especially in the context of integrating renewable energy to existing power grid. It enables the

Get a quote

IEEE Presentation_Battery Storage 3-2021

IEEE PES Presentation _ Battery Energy Storage and Applications 3/10/2021 Jeff Zwijack Manager, Application Engineering & Proposal Development

Get a quote

Containerized Energy Storage Systems: A Detailed Guide to Their Design

This detailed guide will explore the design and benefits of containerized energy storage systems, shedding light on their potential to revolutionize the energy industry.

Get a quote

How are energy storage containers configured? | NenPower

The configuration of energy storage containers is intricately linked to modular design principles, which play a pivotal role in their functionality and scalability.

Get a quote

6 FAQs about [Overall design of energy storage container]

What are the challenges in designing a battery energy storage system container?

The key challenges in designing the battery energy storage system container included: Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment.

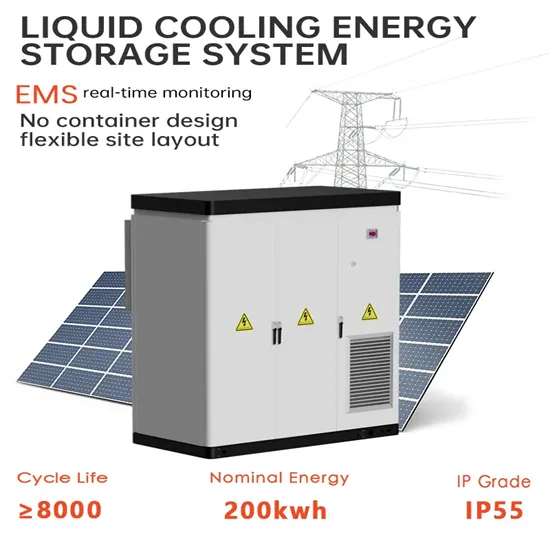

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

What makes a good shipping container design?

Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment. Compliance with International Standards: The container design should meet stringent international standards for shipping containers.

Why should you consider a container design?

The container was also weatherproof, offering protection against environmental elements. Strategically placed access points and an optimized internal space simplified maintenance. The design helped the client reduce operational downtime and maintenance efforts.

What makes a good container?

Weather Resistance: As the container would be kept outdoors, it must withstand environmental conditions like rain, extreme temperatures, and high winds, while keeping the internal components safe. Doors, Frames and Handles: Aesthetic design was also a key consideration. We needed doors, frames, and handles to be visually appealing and easy to use.

Can CFD simulation be used in containerized energy storage battery system?

Therefore, we analyzed the airflow organization and battery surface temperature distribution of a 1540 kWh containerized energy storage battery system using CFD simulation technology. Initially, we validated the feasibility of the simulation method by comparing experimental results with numerical ones.

Guess what you want to know

-

Container energy storage structure design

Container energy storage structure design

-

The complete design scheme of the working principle of energy storage container

The complete design scheme of the working principle of energy storage container

-

Energy Storage Container Design and Development Process

Energy Storage Container Design and Development Process

-

Chad Energy Storage Container Park Design

Chad Energy Storage Container Park Design

-

Energy storage container assembly automation design

Energy storage container assembly automation design

-

Container Energy Storage Electrical System Design

Container Energy Storage Electrical System Design

-

The role of 5mwh energy storage container

The role of 5mwh energy storage container

-

Tonga Energy Storage Cabinet Container BESS Price

Tonga Energy Storage Cabinet Container BESS Price

-

Honduras Lead-Acid Battery Energy Storage Container

Honduras Lead-Acid Battery Energy Storage Container

-

Energy Storage Container Telecommunications Energy Storage Cleaning

Energy Storage Container Telecommunications Energy Storage Cleaning

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.