What is the Battery Module?

Battery modules are made up of multiple individual cells, whereas a cell is the basic unit of a battery that stores and releases electrical energy. A module is a larger, more

Get a quote

What Are Battery Cells, Battery Modules, And Battery Packs?

In this article, we''ll dive deep into the distinctions between battery cells, modules, and packs, equipping you with the knowledge to confidently identify and work with these key

Get a quote

LLVD & BLVD in Base Station Power Cabinets

LLVD and BLVD Protection in Base Station Power Cabinets Introduction In modern communication networks, base stations, as core infrastructure, are

Get a quote

Voltage difference between modules

For modules connected in series within a pack, it is generally recommended to keep the voltage difference between modules below 1-2% to maintain proper balance and

Get a quote

Battery cabinet for safely charging lithium-ion batteries

Whether you use a few batteries or many, large or small: Batteryguard offers a suitable battery cabinet for every situation. We provide compact models that

Get a quote

Battery Cell VS Battery Module VS Battery Pack

Understanding the differences between battery cells, modules, and packs is essential for designing efficient energy storage systems. This article examines

Get a quote

Understanding Battery Voltage: A Complete Guide

Battery voltage measures the electric potential difference between a battery''s terminals and is critical in determining its state of charge and

Get a quote

Choosing the Right Lithium Ion Battery Cabinet: A

Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

Get a quote

Ultimate Guide to Lithium-Ion Battery Voltage Chart

Different lithium battery materials typically have different battery voltages caused by the differences in electron transfer and chemical reaction processes. Most popular voltage

Get a quote

Battery Cell VS Battery Module VS Battery Pack

Understanding the differences between battery cells, modules, and packs is essential for designing efficient energy storage systems. This article examines their construction,

Get a quote

Lithium-Ion Battery Cell Voltage: What You Need to Know

Lithium-ion battery cell voltage refers to the electrical potential difference between the positive and negative terminals of a battery cell. This voltage determines the energy output

Get a quote

Ultimate Guide to Lithium-Ion Battery Voltage Chart

Lithium-ion battery voltage chart represents the state of charge (SoC) based on different voltages. This Jackery guide gives a detailed overview of lithium-ion batteries, their

Get a quote

Battery Pack Cell Voltage Difference and Solution Part 1

In this article, we''ll dive deep into the distinctions between battery cells, modules, and packs, equipping you with the knowledge to confidently

Get a quote

Difference between Battery Module And Battery Pack

What is in a Battery Pack? A battery pack is made up of one or more batteries that are connected together to provide a higher voltage than a

Get a quote

Lithium battery cabinet voltage requirements

Unlock the full potential of lithium batteries by mastering the intricacies of lithium battery voltage with this comprehensive guide. From basic concepts to advanced applications, this article is

Get a quote

Voltage difference in DIY battery pack

When packs are assembled they are at full charge and when hooked to the bus they parallel out to be exactly the same voltage. After the pack is built, the iCharger is used to

Get a quote

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

Get a quote

Understanding Battery Basics: Chemistry, Voltage,

Batteries store chemical energy and convert it into electrical energy, powering countless devices from cars to laptops. Key concepts in

Get a quote

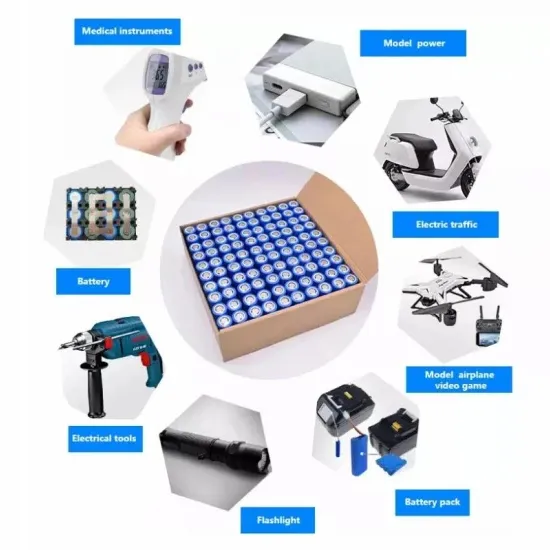

What is Battery Cell, Battery Module, and Battery Pack?

It is important to understand the difference between a battery cell, battery module and battery pack if you work in industries such as electric

Get a quote

Battery Pack Cell Voltage Difference and Solution Part

Voltage difference beyond a certain range will affect the life and safety of a battery pack, Grepow will introduce you to the causes of that.

Get a quote

What Is Battery Charging Rate

How Different Battery Types Affect Charging Rates Lithium-ion (Li-ion) Battery Charging Characteristics Lead-Acid vs. Lithium: Key Differences Temperature''s Critical Role in

Get a quote

Lithium Ion Battery Charging Cabinets

Justrite''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9-layer

Get a quote

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Get a quote

Battery Pack Cell Voltage Difference and Solution Part 1

For battery packs, the voltage difference between individual cells is one of the main indicators of consistency. The smaller the voltage difference, the better the consistency of the

Get a quote

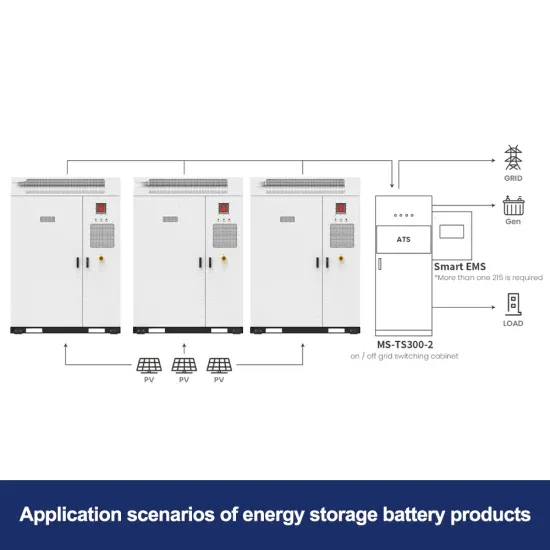

What is the voltage of the energy storage battery cabinet?

While connecting additional battery modules can increase the total voltage, careful consideration must be given to the overall system design, grid interface requirements, and

Get a quote

BATTERY CHARGING & STORAGE CABINETS

Lithium-Ion Battery Charging & Storage Cabinets with 1260 degree HotWall (tm) insulation to contain exploding Lithium -Ion Batteries, BUY DIRECT .

Get a quote

6 FAQs about [Voltage difference between different modules in lithium battery station cabinets]

What are the key parameters of a lithium battery?

The key parameters you need to keep in mind, include rated voltage, working voltage, open circuit voltage, and termination voltage. Different lithium battery materials typically have different battery voltages caused by the differences in electron transfer and chemical reaction processes.

What is the structure of a lithium battery?

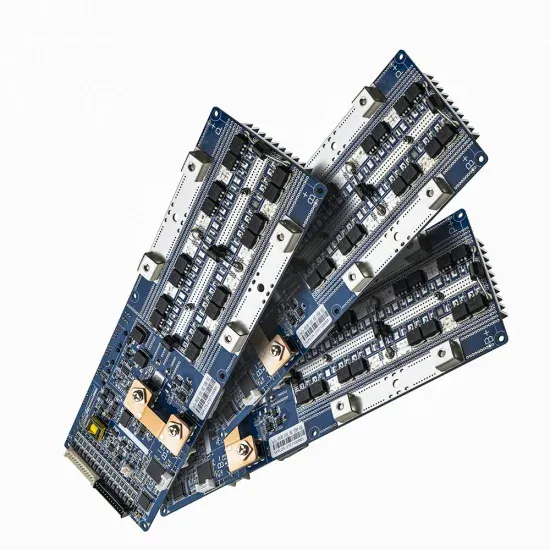

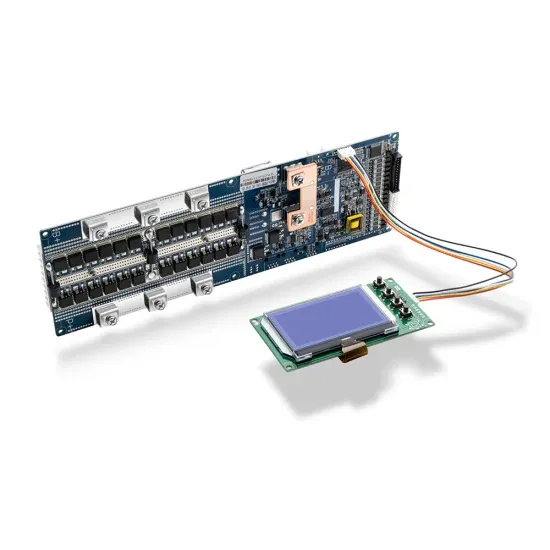

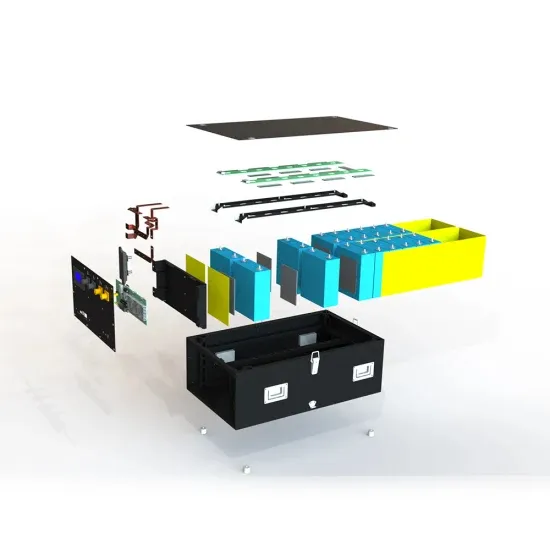

The general structure of lithium batteries is a cell, battery module and battery pack. Battery cell technology is the cornerstone of battery systems. The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in series and parallel.

What is the difference between a lithium ion battery and a battery pack?

While a lithium-ion cell is a single battery unit, a battery pack combines multiple cells in series or parallel. The typical lifespan of lithium-ion batteries is around 300-1000 charge cycles. Voltage vs. Charging Relations The relation between voltage and the battery's charge is often overlooked, but it's important.

Why do lithium batteries have different voltages?

Different lithium battery materials typically have different battery voltages caused by the differences in electron transfer and chemical reaction processes. Most popular voltage sizes of lithium batteries include 12V, 24V, and 48V.

What is the difference between battery module and battery pack?

Battery Module: A group of interconnected battery cells that increases voltage and capacity compared to individual cells. It includes wiring and connectors and may feature a basic battery management system (BMS) for monitoring. Battery Pack: A complete energy storage system containing one or more modules.

What is a battery module?

A battery module is a system composed of a certain number of cells in a designed series and parallel structure as needed. By connecting the cells in series, the voltages of multiple cells are accumulated, thereby achieving an output voltage based on a corresponding multiple of the cell voltage.

Guess what you want to know

-

Price inquiry for customized lithium battery station cabinets in West Africa

Price inquiry for customized lithium battery station cabinets in West Africa

-

Current status of lithium battery station cabinets

Current status of lithium battery station cabinets

-

Uruguay has lithium battery station cabinets

Uruguay has lithium battery station cabinets

-

Where can I find custom lithium battery station cabinets in the Czech Republic

Where can I find custom lithium battery station cabinets in the Czech Republic

-

Calculation of current and voltage of lithium battery station cabinet

Calculation of current and voltage of lithium battery station cabinet

-

How much is the price of custom-made lithium battery station cabinets in Bolivia

How much is the price of custom-made lithium battery station cabinets in Bolivia

-

Standard storage location for lithium battery station cabinets

Standard storage location for lithium battery station cabinets

-

How much does a lithium battery station cabinet cost in Iceland

How much does a lithium battery station cabinet cost in Iceland

-

Lithium battery energy storage power station price trend

Lithium battery energy storage power station price trend

-

Difference between battery pack and lithium battery

Difference between battery pack and lithium battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.