How To Balance A Lithium Batteries: Top and Bottom Balancing

A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery pack.

Get a quote

Battery Balancing: Techniques, Benefits, and How It Works

By balancing the cells, the battery system operates more efficiently, delivering optimal performance and extending the overall lifespan of the battery pack. Why Do We Need Battery

Get a quote

How to Balance Lithium Batteries in Parallel

Balancing lithium battery packs, like individual cells, involves ensuring that all batteries within a system maintain the same state of charge.

Get a quote

Do I Need to Balance Charge Series Battery Packs? Tips for

To maintain battery health, you must balance charge series battery packs. Charge each 12V battery individually before connecting them in series. This balancing process

Get a quote

Battery Balancing: Techniques, Benefits, and How It

By balancing the cells, the battery system operates more efficiently, delivering optimal performance and extending the overall lifespan of the battery pack.

Get a quote

Balance charging Li-ion batteries : r/batteries

Wouldn''t it just make sense to drop the whole BMS paradigm and simply integrate the balancing function into the charger? Even if the cells get a bit out of balance on discharge, you''d bring

Get a quote

LiFePO4 Battery Balancing Guide

This may involve rechecking connections, recalibrating the BMS, or replacing faulty cells or components. How long does it take to balance LiFePO4 batteries? Balancing time for

Get a quote

Master LiPo Balancing: Charging Tips & Tech Guide

Learn why LiPo batteries need balancing, how battery balancers work, charging methods, and tips for safe RC LiPo use. Optimize performance

Get a quote

LiFePO4 Battery Bank in Series (48V or 60V) balancer

Hello folks, I intend to series-connect four or five 12V Lithium batteries to make a 48V or 60V bank for my residential solar project. From my reading here and here, I understand

Get a quote

How to Parallel Balancing. (YEP 99% of us is doing it

Now you want to know how to maintain your precious new purchase: How to best charge lithium-iron-phosphate batteries, how to

Get a quote

Do Lithium Batteries Need to Be Balanced?-Vatrer

Battery balancing refers to the process of equalizing the charge across all cells in a battery pack. The primary purpose of balancing is to ensure that each cell operates within its

Get a quote

How To Balance Lithium-Ion Batteries?

Do lithium-ion batteries need to be balanced? Indeed, when a lithium battery is planned utilizing various cells in arrangement, it is fundamental to structure the electronic

Get a quote

Techniques for Balancing Batteries-Improve Battery

Learn everything about balancing batteries, why it''s important, and how to balance batteries properly to extend their lifespan and improve safety.

Get a quote

Passive Balancing and Active Balancing of Lithium Batteries

Why does the battery need to be balanced? The main reason is that there is always some difference between the cells in a battery pack, such as voltage, internal

Get a quote

How to Achieve EV Battery Balancing?

The battery pack is the central component in every EV and is usually accomplished out of amounts of lithium-ion cells. Despite their synergy, if the temperature at which they are

Get a quote

Do I Need to Balance Charge Series Battery Packs? Tips for

To ensure proper balancing, use a dedicated battery management system (BMS). This system monitors each cell''s voltage and intervenes to balance the pack. Additionally,

Get a quote

Why Proper Cell Balancing is Necessary in Battery Packs

When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell voltages. This is not only for the

Get a quote

Do you need to balance Lifepo4 batteries in series?

1) battery not at same state of charge (not balanced) To your post title, it is important that batteries are balanced. Especially for series connected cells or battery packs.

Get a quote

Why Proper Cell Balancing is Necessary in Battery

When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell

Get a quote

Techniques for Balancing Batteries-Improve Battery Life & Safety

Learn everything about balancing batteries, why it''s important, and how to balance batteries properly to extend their lifespan and improve safety.

Get a quote

Battery Balancer Guide: Optimize Performance & Longevity

Battery balancing and battery balancers are crucial in optimizing multi-cell battery packs'' performance, longevity, and safety. This comprehensive guide will delve into the

Get a quote

How to keep lithium batteries in series balanced? : r/SolarDIY

I have the majority of my batteries connected in parallel first, then I connect them in series to get the voltage I need. Batteries really like being connected in parallel.

Get a quote

How to Balance Lithium Batteries in Parallel

Balancing lithium battery packs, like individual cells, involves ensuring that all batteries within a system maintain the same state of charge. This process is essential when

Get a quote

How to Balance Your Lithium Battery Pack During Installation

Proper lithium battery pack balancing before and during installation is essential for safety, longevity, and optimal performance. Following steps like parallel balancing, using a

Get a quote

6 FAQs about [Pack lithium batteries need to be balanced]

What is balancing lithium battery packs?

Balancing lithium battery packs, like individual cells, involves ensuring that all batteries within a system maintain the same state of charge. This process is essential when multiple battery packs are used together in series or parallel configurations.

Do you know how to balance a lithium battery pack?

Whether you are new to battery building or a seasoned professional, it's totally normal to not know how to balance a lithium battery pack. Most of the time when building a battery, as long as you use a decent BMS, it will balance the pack for you over time. The problem is, this can take a very, very long time.

Why is balancing a lithium battery important?

In lithium batteries, maintaining balance is crucial because it allows for the most efficient use of the battery's total capacity. It also prolongs the battery's lifespan by preventing overcharging or over-discharging of individual cells.

Does a lithium ion battery have a balance problem?

If you built a lithium-ion battery and its capacity is not what you expect, then you more than likely have a balance issue. While it's true that cells connected in parallel will find their own natural balance, the same is not true for cells wired in series. Battery cells in series have no way of transferring energy between one another.

Can a BMS balance a lithium-ion battery pack?

Most of the time when building a battery, as long as you use a decent BMS, it will balance the pack for you over time. The problem is, this can take a very, very long time. Knowing how to manually balance a lithium-ion battery pack can be a crucial tool in your arsenal.

Do all battery chemistries need balancing?

Not all battery chemistries require balancing, but balancing is essential for lithium-ion batteries and other multi-cell systems where consistent charge across cells is crucial for performance and safety. Q2: How Often Should I Perform Battery Balancing? The frequency depends on the battery type, usage, and the balancing system itself.

Guess what you want to know

-

Which industries need to use pack lithium batteries

Which industries need to use pack lithium batteries

-

Does it need to balance the voltage when making a lithium battery pack

Does it need to balance the voltage when making a lithium battery pack

-

Do energy storage lithium batteries need to be connected to the ground

Do energy storage lithium batteries need to be connected to the ground

-

Lithium iron phosphate battery pack requires balanced voltage

Lithium iron phosphate battery pack requires balanced voltage

-

Pack Introduction to Lithium Batteries

Pack Introduction to Lithium Batteries

-

Balanced price of energy storage lithium batteries

Balanced price of energy storage lithium batteries

-

Tajikistan lithium battery pack processing manufacturer

Tajikistan lithium battery pack processing manufacturer

-

Lithium Titanium Phosphate Battery Pack Life

Lithium Titanium Phosphate Battery Pack Life

-

Lithium titanate battery pack high power

Lithium titanate battery pack high power

-

48v 12ah lithium battery pack

48v 12ah lithium battery pack

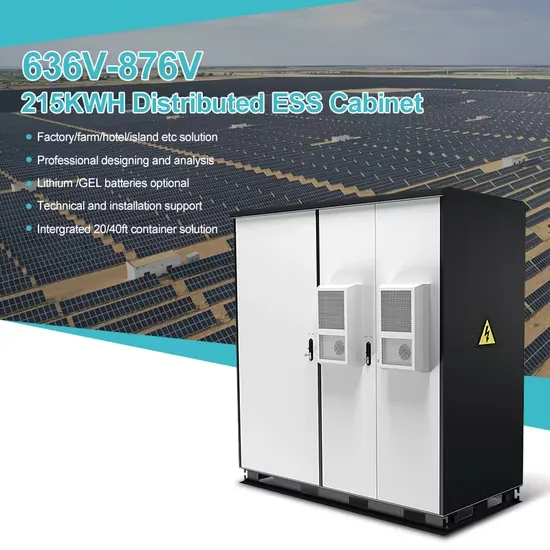

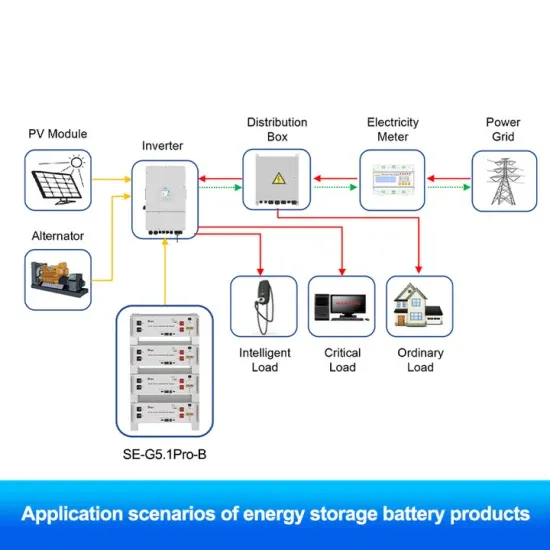

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.