Fire Alarm Panel and External Battery Distance/Location

Different panel manufacturer''s appear to have different requirements on distance external standby battery cabinets can be from the panel, and some specify same room.

Get a quote

E-Micromobility Battery Charging Cabinet Equipment and

• An emergency power shut-off for the battery charging cabinet shall be provided at distance of not less than 10 feet from the cabinet in a conspicuous location readily accessible to emergency

Get a quote

Understanding NFPA 855 Standards for Lithium

NFPA 855 lithium battery standards ensure safe installation and operation of energy storage systems, addressing fire safety, thermal runaway,

Get a quote

The Essential Guide to Energy Storage Building Distance: Safety

Ever wondered why your neighborhood battery farm isn''t right next to the playground? The concept of energy storage building distance is more than real estate

Get a quote

Spaces About Battery Systems | UpCodes

Spaces designated for battery systems must adhere to specific regulations regarding working space, which is measured from the battery cabinet''s edge. For battery racks, a minimum

Get a quote

Understand the codes, standards for battery energy storage systems

Battery energy storage represents a critical step forward in building sustainability and resilience, offering a versatile solution that, when applied within the boundaries of

Get a quote

BATTERY CABINET

The warning sign supplied is for identifying the battery room and provides information about possible hazards. The label should be placed outside the battery room in a visible position.

Get a quote

Battery Energy Storage Systems: Main Considerations for Safe

Battery Energy Storage Systems, or BESS, help stabilize electrical grids by providing steady power flow despite fluctuations from inconsistent generation of renewable

Get a quote

Battery cabinet for safely charging lithium-ion batteries

Whether you use a few batteries or many, large or small: Batteryguard offers a suitable battery cabinet for every situation. We provide compact models that

Get a quote

Battery Room Safety & Installation Guide

Technical document detailing safety and installation guidelines for battery rooms, including ventilation, temperature, and electrical requirements.

Get a quote

Do Lithium Ion Batteries Require A Battery Room? Storage

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.)

Get a quote

Fire Alarm Panel and External Battery Distance/Location

Different panel manufacturer''s appear to have different requirements on distance external standby battery cabinets can be from the panel, and some specify same room. - Does

Get a quote

EG4 BESS Spacing

The following document clarifies BESS (Battery Energy Storage System) spacing requirements for the EG4 WallMount batteries / rack mount six slot battery cabinet installations.

Get a quote

Lithium-Ion Battery Charging Safety Cabinet

Justrite''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9-layer

Get a quote

2018 Title Contents

Abstract Changes in requirements to meet battery room compliance can be a challenge. Local Authorities Having Jurisdictions often have varying requirements based on areas they serve.

Get a quote

Lithium Ion Battery Charging Cabinets

Justrite''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9-layer ChargeGuard™ system that helps minimize

Get a quote

Safety Cabinets for Dangerous Goods | Flammable

Ensure safe storage with Multi Rack''s range of Safety Cabinets, including Class 3 Flammable Liquids (AS1940-2017), Corrosive Substances Safety Cabinets

Get a quote

minimum distance between battery charger and eye wash/shower

We have a project with battery charging room. Would you please let me know the minimum distance between eye wash/shower and battery charger? Does any code requires

Get a quote

Choosing the Right Battery Storage Cabinet: A

Position your lithium ion battery storage cabinet away from flammable items, fuel sources, and areas with high foot traffic. If a fire occurs,

Get a quote

Choosing the Right Battery Storage Cabinet: A Comprehensive Safety

Position your lithium ion battery storage cabinet away from flammable items, fuel sources, and areas with high foot traffic. If a fire occurs, physical separation helps contain the

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get a quote

6 FAQs about [Battery cabinet safety distance]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

What are OSHA regulations for battery handling and storage?

OSHA sets forth regulations that ensure worker safety during battery handling and storage. These include requirements for personal protective equipment and proper training for employees working with batteries.

What are the best practices for storing batteries?

Best practices include using battery cabinets with ventilation holes or ensuring that rooms where batteries are stored have sufficient air circulation. Storing batteries in a non-conductive container protects them from accidental short circuits. Containers made from materials like polypropylene or high-density polyethylene are ideal.

What are the requirements for a battery handling facility?

Floors shall be of acid resistant construction unless protected from acid accumulations. Face shields, aprons, and rubber gloves shall be provided for workers handling acids or batteries. Facilities for quick drenching of the eyes and body shall be provided within 25 feet (7.62 m) of battery handling areas.

Guess what you want to know

-

Distance between batteries in battery cabinet

Distance between batteries in battery cabinet

-

Battery cabinet design safety

Battery cabinet design safety

-

Battery Cabinet and System Safety Requirements

Battery Cabinet and System Safety Requirements

-

Battery Cabinet Safety Operating Procedures

Battery Cabinet Safety Operating Procedures

-

Battery cabinet communication high voltage system safety design

Battery cabinet communication high voltage system safety design

-

Is the energy storage module unit a battery cabinet

Is the energy storage module unit a battery cabinet

-

Battery cabinet logistics costs

Battery cabinet logistics costs

-

Rwanda lithium battery site cabinet charging current

Rwanda lithium battery site cabinet charging current

-

What does DC mean for a mobile outdoor battery cabinet

What does DC mean for a mobile outdoor battery cabinet

-

Lithium titanate battery station cabinet

Lithium titanate battery station cabinet

Industrial & Commercial Energy Storage Market Growth

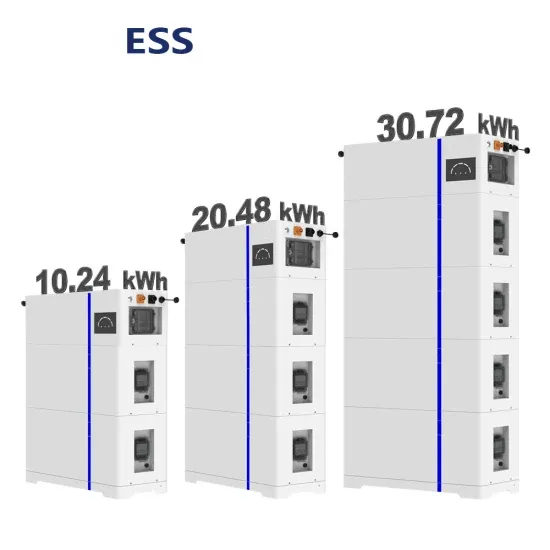

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.