What Is a BMS Battery and Why Need It | Grepow

It acts as the "brain" of the battery pack by continuously monitoring and managing various parameters such as voltage, current, temperature, and state of charge (SoC), thereby

Get a quote

Why is BMS Important in Lithium Batteries? Understanding the

In the ever-evolving world of battery technology, Battery Management Systems (BMS) play a pivotal role in ensuring the safety, efficiency, and longevity of lithium-ion

Get a quote

How Lithium-ion Battery Management Systems Enhance

Understanding Lithium-ion Batteries It''s critical to understand the fundamentals of lithium-ion batteries before delving into the BMS''s function. These batteries are popular because of their

Get a quote

Why is BMS Important in Lithium Batteries? Understanding the

Cell Monitoring and Balancing: The BMS continuously monitors the voltage, temperature, and state of charge of individual cells within a battery pack. It ensures that each

Get a quote

What Is the Role of a Battery Management System (BMS) in Lithium

A Battery Management System (BMS) is essential for the safe and efficient operation of lithium-ion battery packs, particularly in applications such as electric vehicles and

Get a quote

Understanding the Role of the BMS in Modern Lithium Batteries

The Battery Management System is an electronic circuit board built into or attached to a lithium battery pack. Its primary function is to monitor, manage, and protect the battery cells during

Get a quote

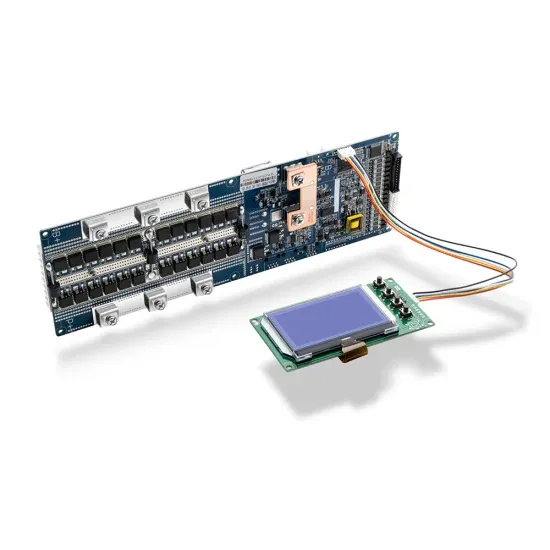

ST BMS kit solution 电池管理系统整体解决方案

Battery management system Automotive BMS must be able to meet critical features such as voltage, temperature and current monitoring, battery state of charge (SoC) and cell balancing

Get a quote

BMS for Lithium-Ion Battery: Essential Guide

Monitors the Battery State: By keeping track of the battery''s voltage, current, and temperature, the BMS ensures that the battery operates within safe limits. This monitoring

Get a quote

BMS for Lithium-Ion Batteries: The Essential Guide to Battery

What is a BMS for Lithium-Ion Batteries? A Battery Management System (BMS) is an electronic control system that manages rechargeable battery packs by monitoring their

Get a quote

Working Principles and Core Functions of Battery BMS

Introduction Battery Protection Circuit Modules (PCMs), also known as Battery Management Systems (BMS), are critical components in

Get a quote

How does lithium battery BMS determine the battery''s safety, life

Using collected data and advanced algorithm models (such as Kalman filtering and neural networks), lithium battery BMS accurately estimates the SOC and SOH of the battery

Get a quote

What Does BMS Mean in Lithium Batteries?

One of the main tasks of a BMS is to keep track of the battery''s voltage. If the voltage becomes too high or too low, it can damage the battery and reduce its lifespan. The

Get a quote

Power Up: The Essential Role of Battery Management Systems in Lithium

2. Why do lithium-ion batteries need a BMS? Lithium-ion batteries require a BMS to prevent overcharging, overheating, and imbalances among cells, which can lead to reduced

Get a quote

How To Choose A BMS For Lithium Batteries

When choosing a BMS for a lithium-ion battery, the most important aspects to consider is the maximum current rating and that the BMS supports the correct number of

Get a quote

What Is a BMS Battery and Why Need It | Grepow

It acts as the "brain" of the battery pack by continuously monitoring and managing various parameters such as voltage, current, temperature, and

Get a quote

How does the battery management system (BMS) work in a lithium battery

Cell Monitoring: The BMS continuously monitors the voltage, temperature, and state of charge (SOC) of each individual cell in the battery pack. This allows it to detect any

Get a quote

How does lithium battery BMS determine the battery''s

Using collected data and advanced algorithm models (such as Kalman filtering and neural networks), lithium battery BMS accurately

Get a quote

What Is A BMS Battery Management System?

A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs. It ensures safety by preventing overcharging, over-discharging,

Get a quote

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Your question about the importance of a Battery Management System (BMS) for lithium-ion battery safety can be answered with a clear explanation. A BMS is essential

Get a quote

How does the battery management system (BMS) work in a

Cell Monitoring: The BMS continuously monitors the voltage, temperature, and state of charge (SOC) of each individual cell in the battery pack. This allows it to detect any

Get a quote

Battery Management System (BMS) for Efficiency and Safety

Learn How Battery Management System (BMS) Optimizes Efficiency and Safety in Electric Vehicles, Energy Storage, and Electronics.

Get a quote

What Is the Function of a Battery Management System?

A BMS monitors each cell within a battery pack (all current lithium batteries for RVs contain a number of smaller "cells" that are wired together to

Get a quote

What Is BMS on a Lithium Battery? A Complete Guide to Its Role

A BMS, short for Battery Management System, is an electronic control unit that monitors and manages the operation of a lithium battery. It ensures the battery works within

Get a quote

What is a BMS for Lithium Batteries?

A Battery Management System (BMS) for lithium batteries is an electronic system that manages and monitors the performance, safety, and longevity of battery packs. By

Get a quote

6 FAQs about [Greek lithium battery bms function]

What are the functions of BMS in lithium batteries?

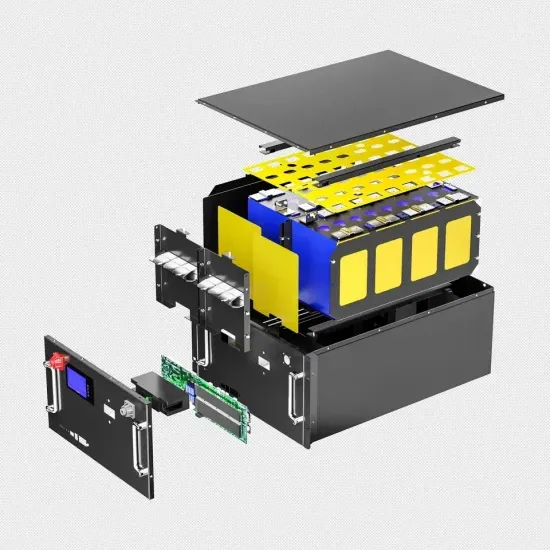

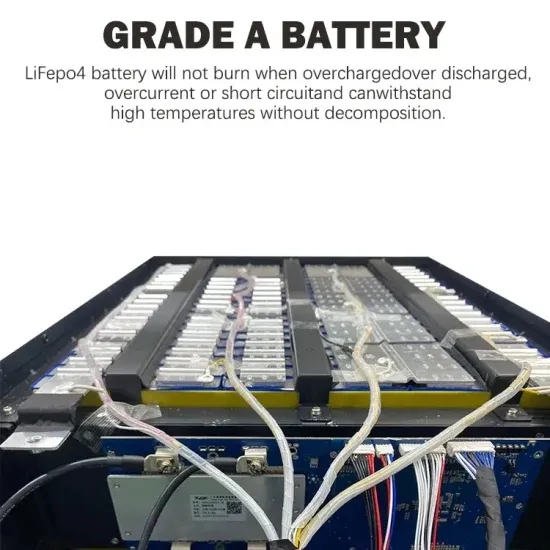

The functions of BMS in lithium batteries can be summarized as comprehensive monitoring, management, and protection of lithium battery packs. The main functions include: Lithium battery BMS utilizes a high-precision sensor network to collect key parameters such as voltage, current, and temperature for each cell in the battery pack in real time.

What happens if a lithium ion battery does not have a BMS?

Without a BMS, lithium-ion batteries can overcharge or over-discharge. This condition can lead to battery damage or even fires. A BMS optimizes the charging process, ensuring longer battery life. It prevents abuse by balancing the charge across individual cells.

Can You charge a lithium battery without a BMS?

Charging a lithium battery without a BMS is risky. The charger alone cannot monitor individual cell voltages or temperatures, so it cannot prevent overcharging of single cells within a pack. The BMS ensures that charging stops or is adjusted if any cell reaches unsafe voltage or temperature levels, preventing damage or fire risk.

Do EV batteries need a BMS?

However, if you have multiple independent battery packs, each pack requires its own BMS to monitor and protect its cells. For example, in an EV with multiple battery modules, each module may have a dedicated BMS, or a centralized BMS may oversee all modules, depending on the system design. Can I use lithium battery without BMS?

What is a battery management system (BMS)?

Modern lithium batteries are more than just rows of chemical cells—they're smart energy systems, and the Battery Management System (BMS) is their brain. Without a properly functioning BMS, even the most advanced battery pack can fail, shut down, or become a safety hazard.

What does BMS mean in a battery?

At its core, BMS stands for Battery Management System. It's an essential component for lithium-ion batteries, which are commonly used in electric vehicles (EVs), energy storage systems (ESS), and other devices that require rechargeable batteries.

Guess what you want to know

-

Greek lithium battery bms wholesale

Greek lithium battery bms wholesale

-

Kyrgyzstan lithium battery bms function

Kyrgyzstan lithium battery bms function

-

Colombian lithium battery BMS module

Colombian lithium battery BMS module

-

Seychelles lithium battery BMS characteristics

Seychelles lithium battery BMS characteristics

-

Congo Kinshasa BMS lithium battery

Congo Kinshasa BMS lithium battery

-

Kyrgyzstan professional lithium battery bms system

Kyrgyzstan professional lithium battery bms system

-

Bulgaria lithium battery BMS solution

Bulgaria lithium battery BMS solution

-

Hungarian lithium iron phosphate bms battery

Hungarian lithium iron phosphate bms battery

-

Cook Islands energy storage lithium battery bms management system

Cook Islands energy storage lithium battery bms management system

-

Sudan lithium battery bms characteristics company

Sudan lithium battery bms characteristics company

Industrial & Commercial Energy Storage Market Growth

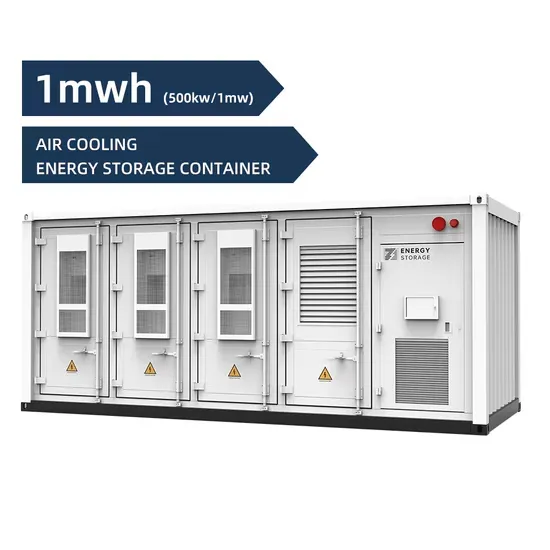

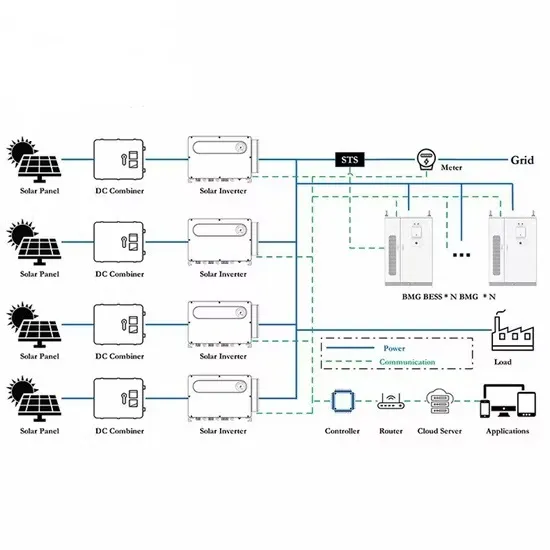

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

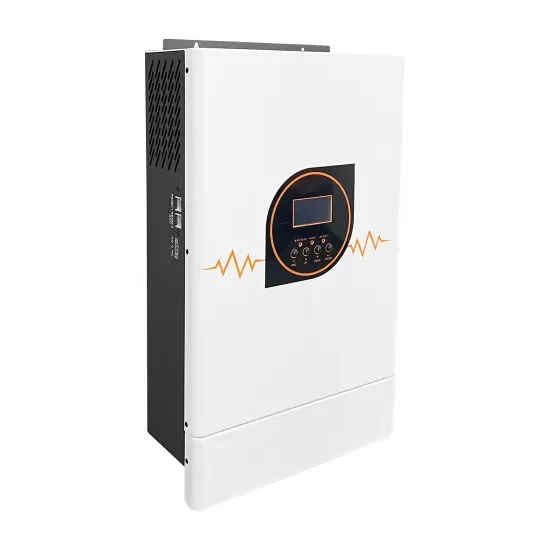

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.