TDK opens ₹3,000 cr lithium-ion battery plant in Haryana to

Sohna (Haryana): Japanese firm TDK Corporation, which supplies batteries to Apple, opened a Rs 3,000 crore lithium-ion battery plant in Haryana''s Sohna. The production

Get a quote

Moldova lithium battery industrial park goes into production

What are the production steps in lithium-ion battery cell manufacturing? Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and

Get a quote

SSOE Group | Battery Manufacturing | Battery Plant

SSOE supports the battery manufacturing process at every point in the supply chain—from battery materials production to cell production, and battery

Get a quote

Moldova lithium battery project

The Aurora joint venture lithium conversion plant is expected to have an initial production capacity of 28,000 to 35,000 tonnes of battery-grade lithium hydroxide per year.

Get a quote

Lithium-ion battery production in Moldova | حلول الطاقة الشمسية

In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting with a brief overview of existing

Get a quote

Moldova lithium-ion battery production project

The facility, which is expected to come online in late 2027, will manufacture various types of lithium-ion cells for commercial, industrial and defense applications, with a production capacity

Get a quote

Europe will open 250 battery factories by 2033. What are the

Due to its significant market, it''s natural that its national company Freyr has invested 1.7 billion euros to open a state-of-the-art factory in Mo i Rana. The facility is set to be

Get a quote

Top Lithium-Ion Battery Manufacturers Suppliers in Moldova

Simply put, a lithium-ion battery (commonly referred to as a Li-ion battery or LIB) is a type of rechargeable battery that is commonly used for portable electronics and electric vehicles.

Get a quote

Europe will open 250 battery factories by 2033. What

Due to its significant market, it''s natural that its national company Freyr has invested 1.7 billion euros to open a state-of-the-art factory in Mo i

Get a quote

Lyten building lithium-sulfur battery ''gigafactory'' in Reno

The Lyten facility will allow for the production of a domestically manufactured battery by manufacturing cathode active materials and lithium metal anodes and also

Get a quote

13 Largest Battery Manufacturers In The World [2025]

Did you know? China is the undisputed leader in battery manufacturing, dominating the global production of essential battery materials

Get a quote

Battery Cell Production in Europe (as of May 2024)

"Battery-News" presents an up-to-date overview of planned as well as already existing projects in the field of battery cell production.

Get a quote

Lithium ion Battery Manufacturing Plant Cost Report 2024:

Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an lithium ion battery manufacturing plant. The report

Get a quote

How is Moldova s new energy lithium battery

Expect new battery chemistries for EVs as government funding boosts manufacturing this year. In the midst of the soaring demand for EVs and renewable power and an explosion in battery

Get a quote

Current and future lithium-ion battery manufacturing

Here in this perspective paper, we introduce state-of-the-art manufacturing technology and analyze the cost, throughput, and energy consumption based

Get a quote

Which factory is recommended for producing Moldova batteries

Natron Energy starts commercial-scale sodium-ion manufacturing The Natron factory in Michigan, which formerly hosted lithium-ion production lines. Image: Businesswire. Natron Energy has

Get a quote

ProLogium Leads the Way to Solid-State Battery Commercialization

At the heart of this breakthrough is ProLogium''s proprietary SF-Ceramion Superfluidized All-Inorganic Solid-State Electrolyte, completing the final piece of the solid-state lithium ceramic

Get a quote

Poland: why is it the new European epicenter of battery factories?

Poland is rapidly becoming a magnet for investments in battery factories thanks to its skilled workforce and government programmes promoting electromobility. Which

Get a quote

Lithium-Ion Battery Manufacturing Plant: Setup & Cost

The lithium-ion battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Get a quote

Battery production in Moldova

A summary of CATL''''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14 key processes are outlined and described in

Get a quote

Groundbreaking Lithium Extraction Plant Launches in

The first phase is expected to produce about 25,000 metric tons of battery-grade lithium hydroxide monohydrate annually, sufficient to support

Get a quote

Guess what you want to know

-

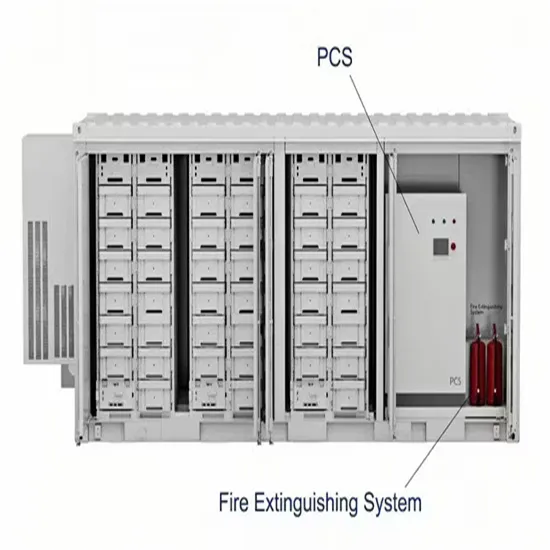

Ethiopia lithium battery station cabinet production plant

Ethiopia lithium battery station cabinet production plant

-

Lithium battery pack production plant in Indonesia

Lithium battery pack production plant in Indonesia

-

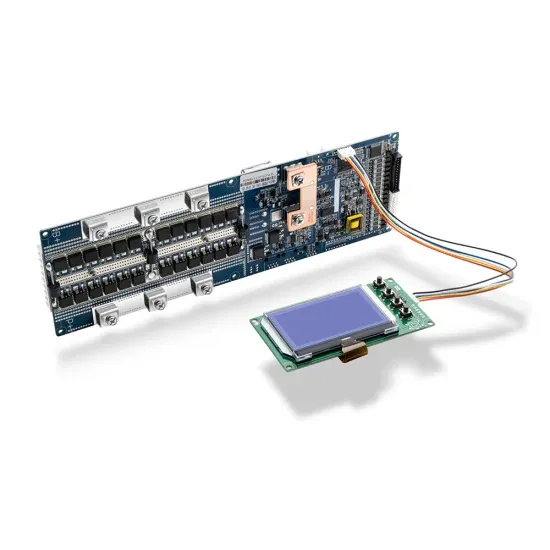

Safety production requirements for lithium battery packs

Safety production requirements for lithium battery packs

-

Specializing in the production of lithium iron phosphate battery packs

Specializing in the production of lithium iron phosphate battery packs

-

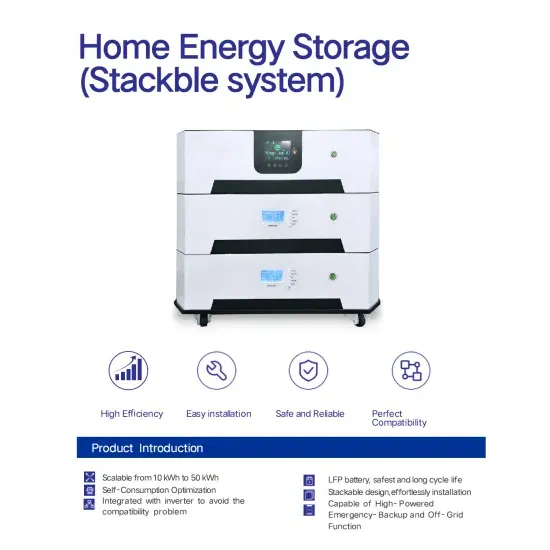

Vanuatu Energy Storage Low-Temperature Lithium Battery Plant

Vanuatu Energy Storage Low-Temperature Lithium Battery Plant

-

Moldova energy storage low temperature lithium battery

Moldova energy storage low temperature lithium battery

-

North Macedonia lithium battery energy storage cabinet assembly plant

North Macedonia lithium battery energy storage cabinet assembly plant

-

Guyana Energy Storage Low-Temperature Lithium Battery Plant

Guyana Energy Storage Low-Temperature Lithium Battery Plant

-

12Ah lithium battery pack production

12Ah lithium battery pack production

-

Production of outdoor lithium battery packs

Production of outdoor lithium battery packs

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.