Base Station Energy Storage Quality | HuiJue Group E-Site

With global 5G base stations projected to exceed 7 million by 2025, base station energy storage quality has become the linchpin of network reliability. But why do 23% of

Get a quote

Microsoft Word

Executive Summary Codes, standards and regulations (CSR) governing the design, construction, installation, commissioning and operation of the built environment are intended to protect the

Get a quote

EES Station Commissioning: Procedures & Safety

Learn about the integral process of commissioning electrochemical energy storage stations, including procedures, safety measures, and

Get a quote

What are the Essential Site Requirements for Battery Energy

Learn about site selection, grid interconnection, permitting, environmental considerations, safety protocols, and optimal design for energy efficiency. Ideal for developers

Get a quote

The BESS System: Construction, Commissioning, and O&M Guide

How often should we conduct regular inspection tours for an energy storage power cabinet? We should conduct regular on-site inspection tours with fixed inspection items at set intervals.

Get a quote

Saudi Aramco Suppliers Safety Management System

The purpose of this manual is to define the Suppliers Safety Management System (SSMS) and help our suppliers to manage the safety of their facilities throughout the kingdom - and to

Get a quote

Comprehensive Guide to Inspecting Fully Integrated

To ensure the reliability, efficiency, and safety of these systems, regular inspections are essential. This article will guide you through the key

Get a quote

EES Station Commissioning: Procedures & Safety | EB BLOG

Learn about the integral process of commissioning electrochemical energy storage stations, including procedures, safety measures, and regulatory requirements.

Get a quote

Site-Specific Measures for Large-Scale Lithium Battery Energy

Explore the critical safety measures for large-scale lithium battery energy storage systems (BESS), including fire suppression, toxic fume mitigation, and emergency response strategies,

Get a quote

Fire Inspection Requirements for Battery Energy

Fire inspections are a crucial part of ensuring the safety and reliability of these systems. This insights post delves into the key requirements and best

Get a quote

Utility-scale battery energy storage system (BESS)

Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and conversion – and

Get a quote

Coordinated Optimization for Energy Efficient Thermal Management

5G mobile communication system achieve better network performance while causing a significant increase in energy consumption, which hinders the sustainable

Get a quote

Establishment Search | Occupational Safety and Health

Establishment Search Reflects inspection data through 09/04/2025 Use our establishment search to locate OSHA enforcement inspections by establishment name. You can also search by a

Get a quote

Comprehensive Guide to Inspecting Fully Integrated BESS

To ensure the reliability, efficiency, and safety of these systems, regular inspections are essential. This article will guide you through the key aspects of inspecting a

Get a quote

National Fire Protection Association BESS Fact Sheet

The table below, which summarizes information from a 2019 Fire Protection Research Foundation (FPRF) report, "Sprinkler Protection Guidance for Lithium-Ion Based Energy Storage

Get a quote

Fire Inspection Requirements for Battery Energy

Therefore, comprehensive fire safety measures and regular inspections are essential to mitigate these risks. Key Components of Fire Inspections for

Get a quote

Commissioning of BESS

Verify and test that the individual electrical, mechanical components of the system are ready for start-up. Verify and test that all safety systems are installed and operating. Note: Is 3rd party

Get a quote

Inspection of health and safety management systems

Organisations are required by law to have effective management systems to control the risks arising from their activities. Arising from research which led to the publication of ''Successful

Get a quote

Battery Energy Storage System Inspection and Testing

These Guidelines provide information on the Inspection and Testing procedures to be carried out by the eligible consumer at the end of the construction of a BESS System, in order to connect

Get a quote

Energy Efficient Thermal Management of 5G Base Station Site

The rapid development of Fifth Generation (5G) mobile communication system has resulted in a significant increase in energy consumption. Even with all the efforts made in terms of network

Get a quote

Siting and Safety Best Practices for Battery Energy Storage

The safety plan should include: hazard detection systems; means of protecting against incipient fires; and ventilation and/or cooling strategies for protecting against thermal runaway, fires,

Get a quote

Inspection of offshore installations and operators

Functional Safety Inspection Guide (PDF) Health Risk Management (PDF) Hydrocarbon Active Fire Protection (PDF) Ionising Radiation (PDF) Loss of Containment (LoC) - Version 2 March

Get a quote

Enforcement and Compliance History Online | US EPA

Use EPA''s Enforcement and Compliance History Online website to search for facilities in your community to assess their compliance with environmental regulations. You can use ECHO to:

Get a quote

Fire Inspection Requirements for Battery Energy Storage Systems

Fire inspections are a crucial part of ensuring the safety and reliability of these systems. This insights post delves into the key requirements and best practices for conducting fire

Get a quote

Battery Energy Storage System Procurement Checklist

Provides federal agencies with a standard set of tasks, questions, and reference points to assist in the early stages of battery energy storage

Get a quote

6 FAQs about [Base Station Energy Management System On-site Safety Inspection]

Why are fire codes important for Bess installations?

In particular, fire codes are critical for BESS installations due to the potential fire risks associated with large-scale battery systems. Installing fire suppression systems, maintaining safe distances from other structures, and implementing clear safety signage are all mandatory in most locations.

What are the energy storage operational safety guidelines?

In addition to NYSERDA’s BESS Guidebook, ESA issued the U.S. Energy Storage Operational Safety Guidelines in December 2019 to provide the BESS industry with a guide to current codes and standards applicable to BESS and provide additional guidelines to plan for and mitigate potential operational hazards.

What is a battery ESS?

Battery ESS are the most common type of new installation and are the focus of this fact sheet. DID YOU KNOW? Battery storage capacity in the United States is expected to more than double between 2022 and 2025 from 9.4 GW to 20.8 GW, according to the U.S. Energy Information Administration.

What is the battery energy storage system guidebook?

NYSERDA published the Battery Energy Storage System Guidebook, most-recently updated in December 2020, which contains information and step-by-step instructions to support local governments in New York in managing the development of residential, commercial, and utility-scale BESS in their communities.

What are the sections of energy storage project guide?

The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various aspects such as foundation construction, battery and inverter installation, wiring, system testing, monitoring, fault handling, and preventive maintenance. 1. Energy Storage Project Construction 2.

What are the environmental and site preparation considerations before construction?

Environmental and Site Preparation Considerations Before construction begins, the site must be prepared to support the installation of a BESS. This includes assessing the site’s soil and ensuring that it is stable enough to support the weight of the batteries and other infrastructure.

Guess what you want to know

-

Australian base station energy management system power generation

Australian base station energy management system power generation

-

Myanmar s photovoltaic base station energy management system

Myanmar s photovoltaic base station energy management system

-

Brazil Base Station Energy Management System Base Station Power Generation Manufacturer

Brazil Base Station Energy Management System Base Station Power Generation Manufacturer

-

Nicaragua 5G Base Station Energy Management System Project

Nicaragua 5G Base Station Energy Management System Project

-

Vanuatu Base Station Energy Management System Energy Storage

Vanuatu Base Station Energy Management System Energy Storage

-

How much does a base station energy management system cost

How much does a base station energy management system cost

-

What wind power system is used in the base station energy management system

What wind power system is used in the base station energy management system

-

How much does the North African base station energy management system cost

How much does the North African base station energy management system cost

-

Base Station Energy Management System Reflections

Base Station Energy Management System Reflections

-

Safety price of communication base station energy storage system

Safety price of communication base station energy storage system

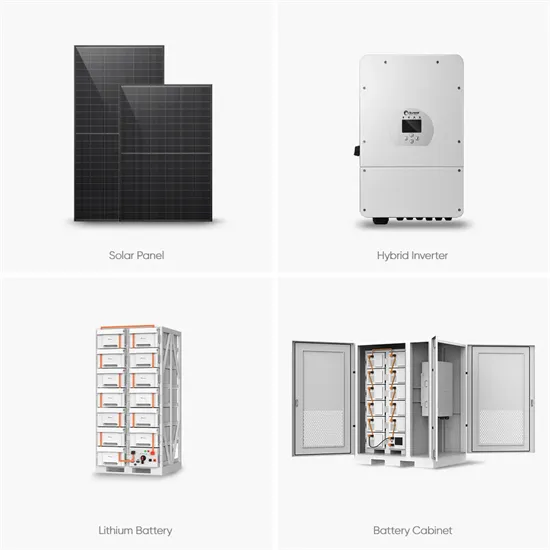

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.