Crystalline silicon

These cells are assembled into solar panels as part of a photovoltaic system to generate solar power from sunlight. In electronics, crystalline silicon is typically the monocrystalline form of

Get a quote

Monocrystalline Silicon

Monocrystalline Silicon: Single-Crystal Silicon Plays A Crucial Role In Solar Panels By Efficiently Converting Sunlight Into Electricity Production Process of Monocrystalline Silicon

Get a quote

The structure of a photovoltaic module

The structure and materials used in the PV panel manufacturing process are very similar independently from the different types of solution. That is why a

Get a quote

What Is Monocrystalline Silicon and Why Is It Dominant in Solar Panels?

The dominance of monocrystalline silicon in the solar panel market is expected to continue as demand for renewable energy solutions rises. With the global push towards clean

Get a quote

Monocrystalline Silicon

In the production of solar cells, monocrystalline silicon is sliced from large single crystals and meticulously grown in a highly controlled environment. The cells are usually a few centimeters

Get a quote

Silicon Solar Cell

Silicon ingots of mono-crystalline crystal or solar-grade poly-crystalline silicon are then sliced by band or wire saw into mono-crystalline and poly-crystalline wafers into 156 × 156 mm 2 size

Get a quote

Photovoltaic (PV) Cell Types | Monocrystalline,

The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar panels, and

Get a quote

Unleashing the Power of Monocrystalline Solar Panels:

With their single-crystal silicon structure, monocrystalline solar panels harness the sun''s rays with unrivaled precision, boasting conversion rates that surpass their polycrystalline

Get a quote

Monocrystalline Solar Panel Efficiency, Construction

Monocrystalline panels are more efficient because they are made from high-purity silicon with a uniform crystal structure. This allows electrons

Get a quote

Monocrystalline vs. Polycrystalline Solar Cells

The two dominant semiconductor materials used in photovoltaics are monocrystalline silicon—a uniform crystal structure—and large-grained

Get a quote

Solar Panel

Monocrystalline solar panels are made from single-crystal silicon, resulting in their distinctive dark black hue. This uniform structure, with fewer grain boundaries, ensures high

Get a quote

Unleashing the Power of Monocrystalline Solar

With their single-crystal silicon structure, monocrystalline solar panels harness the sun''s rays with unrivaled precision, boasting conversion

Get a quote

Structure of monocrystalline solar cell

In this study, various nonconductive substrates were used. The resulting samples were analyzed using various techniques to evaluate their structural, morphological, and optical characteristics....

Get a quote

Mono-crystalline Solar Cells

The silicon used to make mono-crystalline solar cells (also called single crystal cells) is cut from one large crystal. This means that the internal structure is highly ordered and it is easy for

Get a quote

Monocrystalline silicon: efficiency and manufacturing

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline

Get a quote

Mono-crystalline Solar Cells

Mono-crystalline Silicon The silicon used to make mono-crystalline solar cells (also called single crystal cells) is cut from one large crystal. This means that the internal structure is highly

Get a quote

What is Monocrystalline Solar Panel: A Consolidated

Monocrystalline panels have a larger surface area due to the pyramid cell pattern. This enables them to gather more energy from the sun.

Get a quote

What is Monocrystalline Solar Panel: A Consolidated Guide

Monocrystalline panels have a larger surface area due to the pyramid cell pattern. This enables them to gather more energy from the sun. As they are made without any mixed

Get a quote

Monocrystalline solar panels: a comprehensive guide

Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by a protective glass and an external

Get a quote

Comprehensive Guide to Monocrystalline Solar Panel

The efficiency of monocrystalline solar panels is due to the purity of the silicon used in their manufacture. Monocrystalline silicon has a more

Get a quote

Monocrystalline Solar Panel Efficiency, Construction & Functionality

Monocrystalline panels are more efficient because they are made from high-purity silicon with a uniform crystal structure. This allows electrons to move more freely, reducing

Get a quote

Monocrystalline Silicon

1.2.1.1 Monocrystalline Silicon Solar Cell The crystal structure of monocrystalline silicon is homogenous, which means the lattice parameter, electronic properties, and the orientation

Get a quote

Structure of monocrystalline solar cell

In this study, various nonconductive substrates were used. The resulting samples were analyzed using various techniques to evaluate their structural,

Get a quote

Photovoltaic Basics (Part 1): Know Your PV Panels for Maximum

In a photovoltaic panel, electrical energy is obtained by photovoltaic effect from elementary structures called photovoltaic cells; each cell is a PN-junction semiconductor diode

Get a quote

Monocrystalline silicon: efficiency and manufacturing process

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which

Get a quote

Monocrystalline vs. Polycrystalline Solar Cells

Solar panels are composed of multiple solar cells, typically made from silicon or other semiconductors, which convert energy from sunlight into electric current.

Get a quote

Monocrystalline solar cell Figure 8: Monocrystalline

Download scientific diagram | Monocrystalline solar cell Figure 8: Monocrystalline solar cell structure. (Askari Mohammad, 2015) from publication: A Review On

Get a quote

Guess what you want to know

-

Monocrystalline silicon photovoltaic panel capacity

Monocrystalline silicon photovoltaic panel capacity

-

Photovoltaic panel monocrystalline silicon power

Photovoltaic panel monocrystalline silicon power

-

Norwegian monocrystalline silicon photovoltaic panel manufacturer

Norwegian monocrystalline silicon photovoltaic panel manufacturer

-

20w monocrystalline silicon photovoltaic solar panel

20w monocrystalline silicon photovoltaic solar panel

-

Syrian monocrystalline silicon photovoltaic panel specifications

Syrian monocrystalline silicon photovoltaic panel specifications

-

How much does a 500w monocrystalline silicon photovoltaic panel cost

How much does a 500w monocrystalline silicon photovoltaic panel cost

-

700w monocrystalline silicon photovoltaic panel

700w monocrystalline silicon photovoltaic panel

-

The power generation efficiency of monocrystalline silicon photovoltaic panels

The power generation efficiency of monocrystalline silicon photovoltaic panels

-

Photovoltaic panels are made of monocrystalline silicon

Photovoltaic panels are made of monocrystalline silicon

-

Angola monocrystalline photovoltaic panel manufacturer

Angola monocrystalline photovoltaic panel manufacturer

Industrial & Commercial Energy Storage Market Growth

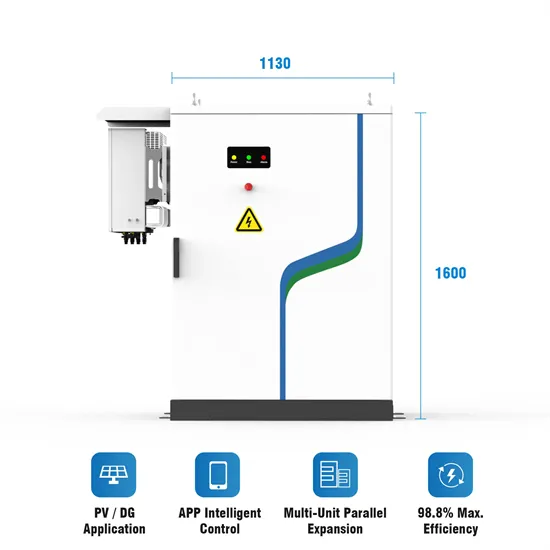

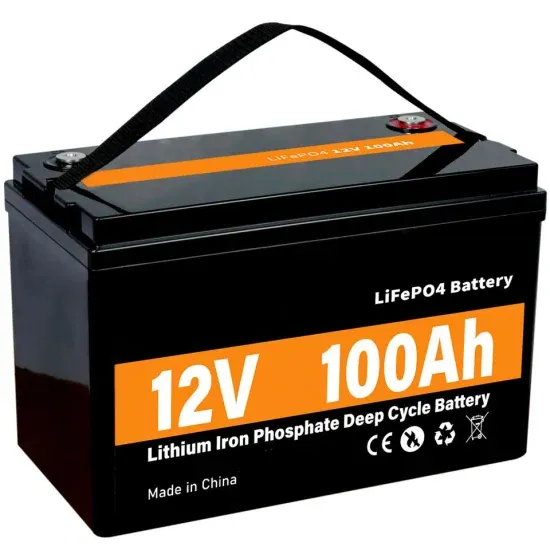

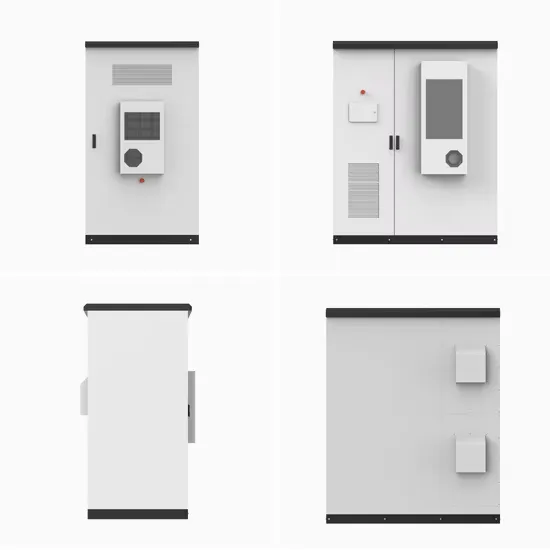

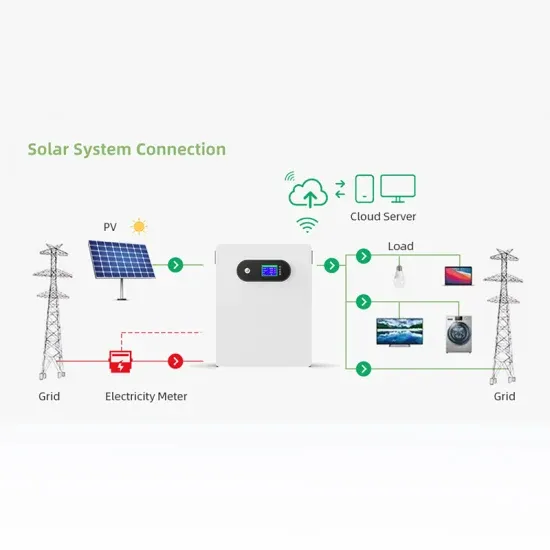

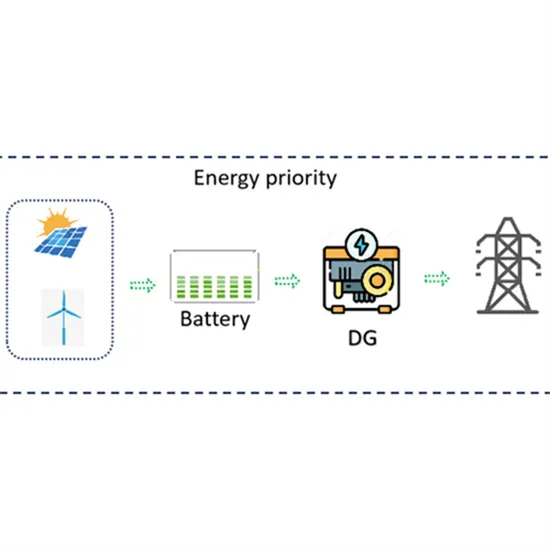

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

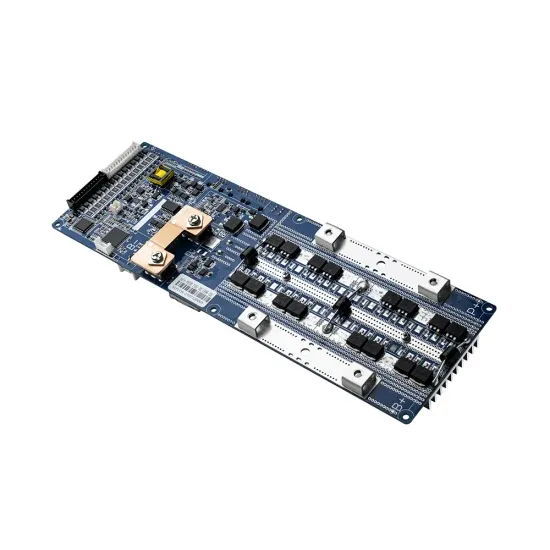

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.