Experimental and Numerical Investigation on an Integrated Thermal

Lightweight power battery modules with outstanding thermal performance are urgently required given the rapid development of electric vehicles. This study proposes a

Get a quote

Comprehensive review of thermal management strategies for

3 days ago· To enable the prediction of battery behavior, the article introduces the Battery Management System (BMS) and two prediction methods (model-based and AI-based

Get a quote

46% of battery related power failures | C&I Energy Storage System

Articles related (70%) to "46% of battery related power failures" Energy Storage Battery Cabinet Installation: Your Roadmap to Safety and Efficiency Let''s face it – energy storage battery

Get a quote

17.5kw Battery Thermal Management System/Bess Container

17.5kw Battery Thermal Management System/Bess Container Cooling Solution Cabinet Air Conditioner 60kbtu Rittal Nvent Hoffman Kooltronic, Find Details and Price about Bess

Get a quote

Liquid-Cooled Battery Storage Cabinets: The Next Frontier in

As global renewable capacity surges past 4,500 GW, a critical question emerges: How can we prevent energy storage systems from becoming their own worst enemies? The answer might

Get a quote

Liquid Cooling Battery Cabinet: Modern BESS Technology

Central to the performance, safety, and longevity of these advanced systems is a sophisticated thermal management solution, embodied by the modern Liquid Cooling Battery Cabinet.

Get a quote

PERFORMANCE INVESTIGATION OF THERMAL

ase performance and safety, battery thermal management systems (BTMS) must be effective. It is essential to choose a suitable BTMS based on the function of the battery and mix different app.

Get a quote

Hydrogen Management in Battery Rooms

Lithium-Ion batteries are equipped with a Battery Management (BMS) system that controls the state of charge and monitors battery parameters but cannot control a thermal runaway event

Get a quote

Thermal management solutions for battery energy

The widespread adoption of battery energy storage systems (BESS) serves as an enabling technology for the radical transformation of how

Get a quote

XING Mobility Unveils High-Power 1MWh Immersion-Cooled

Leveraging its world-class thermal management technology, XING continues to drive innovation in the energy storage industry and expand its global reach—accelerating the

Get a quote

Thermal Management Protection Solutions For Battery Energy

Cooling systems are critically important for BESS, providing the thermal stability that is crucial for battery performance, durability, and safety. If applied correctly, the solutions

Get a quote

Optimized thermal management of a battery energy-storage

Modern battery technology also makes possible a battery design with a compact form factor, which follows a recent trend of a denser and more compact design [4]. The

Get a quote

Thermal management solutions for battery energy

Various thermal management solutions are available, and the choice of the optimal solution is informed by the C-rate of the application, and

Get a quote

PERFORMANCE INVESTIGATION OF THERMAL

An experimental and numerical examination of the thermal management of an outdoor battery storage cabinet was conducted by Zhang et al. [20] to gauge the battery surface temperatures

Get a quote

The Complete Guide to Battery Thermal Management System

This is a guide to understanding what a battery thermal management system entails and why it''s critical for the latest applications.

Get a quote

Thermal Management Protection Solutions For Battery Energy

5 days ago· Ahmadian-Elmi and Zhao [1] evaluated thermal management strategies for cylindrical Li-ion battery packs. They assessed the performance, efficiency, cost, and

Get a quote

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

By using a liquid coolant to absorb and dissipate heat directly from the battery modules, these systems can manage thermal loads far more effectively than air-based

Get a quote

How does the energy storage battery cabinet dissipate heat?

Every battery cabinet ideally operates under established thermal management protocols designed to prevent overheating and maintain performance. These protocols

Get a quote

Investigation on topology optimization of cold plate for

Addressing the issue that single liquid cooling/air cooling technology cannot meet the thermal management requirements of the battery under high power

Get a quote

Analysis of Influencing Factors of Battery Cabinet Heat

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation in Electrochemical Energy Storage System [J]. Journal of Electrical Engineering, 2022, 17 (1): 225-233.

Get a quote

How to Keep Battery Storage Cabinets Safe

Prevent thermal runaway in your battery storage cabinet with proper temperature control, quality batteries, BMS, and regular maintenance for enhanced safety.

Get a quote

Thermal management solutions for battery energy storage systems

Various thermal management solutions are available, and the choice of the optimal solution is informed by the C-rate of the application, and the environmental conditions, among

Get a quote

Recent Progresses of Battery Thermal Management Systems

Battery thermal management system (BTMS) based on phase change materials (PCMs) is simple in structure while presenting outstanding performance, but the core

Get a quote

A review of battery thermal management systems using liquid

The lithium-ion battery has strict requirements for operating temperature, so the battery thermal management systems (BTMS) play an important role. Liquid cooling is typically

Get a quote

Thermal Management in Lithium-Ion Batteries: Latest Advances

5 days ago· Ahmadian-Elmi and Zhao [1] evaluated thermal management strategies for cylindrical Li-ion battery packs. They assessed the performance, efficiency, cost, and

Get a quote

Liquid Cooling Battery Cabinet: Discover cutting-edge tech

The Future of Energy Storage is Here The journey towards a sustainable future is powered by innovation, and effective thermal management is a non-negotiable aspect of

Get a quote

6 FAQs about [Battery cabinet thermal management technology]

What is a battery thermal management system?

A battery thermal management system (BTMS) is a component in the creation of electric vehicles (EVs) and other energy storage systems that rely on rechargeable batteries. Its main role is to maintain the temperatures for batteries ensuring their battery safety, efficiency and lifespan.

Are battery energy storage systems transforming the world?

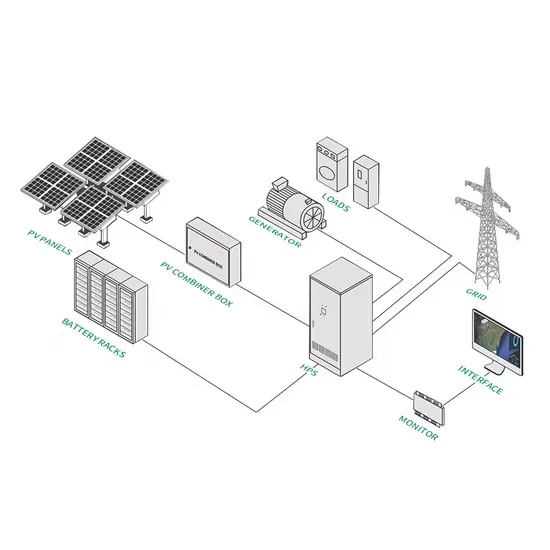

By Adam Wells, Solutions Engineer, Pfannenberg USA Battery energy storage systems (BESS) are helping to transform how the world generates and consumes electricity as we transition from large-scale fossil fuel plants to renewable sources.

What types of thermal management solutions are available?

BESS thermal management solutions include liquid and air cooling; the optimal solution depends primarily on the application’s C-rate and environmental conditions. The most demanding thermal management applications, such as large-scale BESS installation and high C-rate applications, require active liquid cooling.

What is a battery energy storage system (BESS)?

In this context, cooling systems play a pivotal role as enabling technologies for BESS, ensuring the essential thermal stability required for optimal battery performance, durability, and safety. This article explores how implementing battery energy storage systems (BESS) has revolutionised worldwide electricity generation and consumption practices.

Are lithium-ion batteries a viable option for energy storage systems?

However, Lithium-Ion batteries remain the predominant choice for energy storage systems. This is primarily due to their decreasing costs, improved performance, lightweight design, and space-efficient nature, resulting in higher energy density than other battery types. Nevertheless, alternative battery technologies are emerging as viable options.

What is a battery energy storage system?

Businesses also install battery energy storage systems for backup power and more economical operation. These “behind-the-meter” (BTM) systems facilitate energy time-shift arbitrage, in conjunction with solar and wind, to manage and profit from fluctuations in the pricing of grid electricity.

Guess what you want to know

-

Where is the technology for the energy storage cabinet battery

Where is the technology for the energy storage cabinet battery

-

New Energy Battery Cabinet Safety Technology

New Energy Battery Cabinet Safety Technology

-

Current foreign battery cabinet cooling technology

Current foreign battery cabinet cooling technology

-

How to use the battery cabinet temperature management system

How to use the battery cabinet temperature management system

-

Solid-state battery cabinet technology

Solid-state battery cabinet technology

-

Portable outdoor battery cabinet BMS battery management

Portable outdoor battery cabinet BMS battery management

-

Battery cabinet liquid cooling technology principle

Battery cabinet liquid cooling technology principle

-

Sophia Outdoor Communication Battery Cabinet Technology

Sophia Outdoor Communication Battery Cabinet Technology

-

Thermal Battery Site Cabinet

Thermal Battery Site Cabinet

-

Battery Cabinet Base Station Energy Automation Technology Principle

Battery Cabinet Base Station Energy Automation Technology Principle

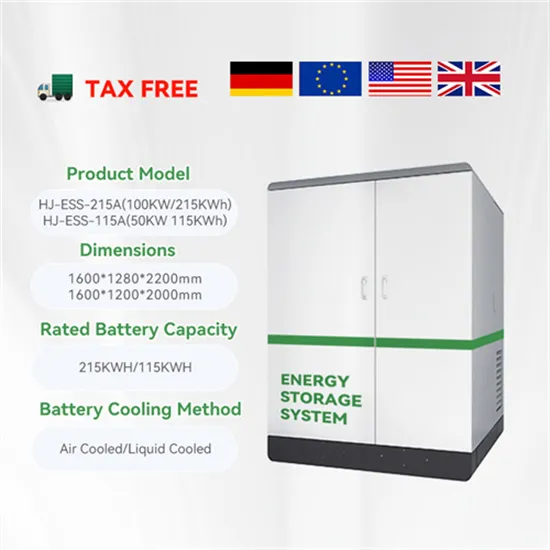

Industrial & Commercial Energy Storage Market Growth

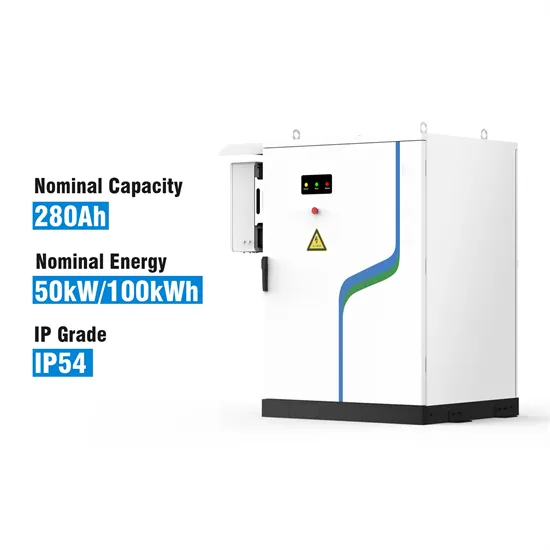

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

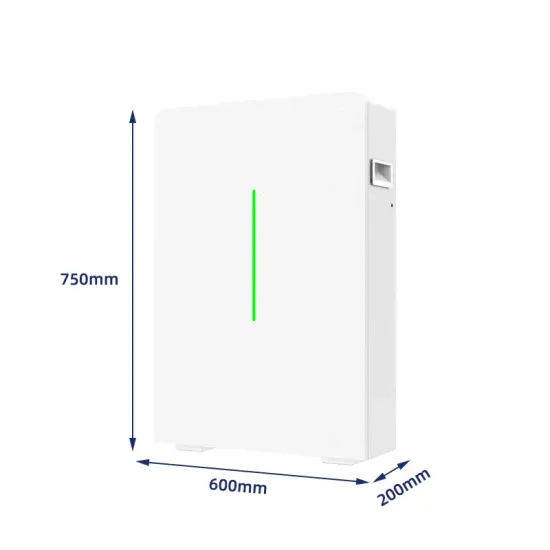

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.