Modeling Ampt String Optimizers in PVsyst

When running a simulation in PVsyst with Ampt String Optimizers, it is important for the inverter maximum operating voltage to be greater than or equal to the optimizer''s maximum absolute

Get a quote

Solar Inverter String Design Calculations

In each string, the connected solar panels should be within 4-20 modules. Since the best MPPT voltage of the phase inverter is around 630V (the best MPPT voltage of the single phase

Get a quote

How Does Heat Affect Solar Inverters?

At the lowest temperature, string voltage cannot exceed the maximum input voltage of the inverter (typically 1000Vdc) and at the highest temperature,

Get a quote

String inverters: What you need to know

A string inverter system aggregates the power output of groups of solar panels in your system into "strings." Multiple strings of panels then

Get a quote

String inverters: What you need to know

A string inverter system aggregates the power output of groups of solar panels in your system into "strings." Multiple strings of panels then connect to a single inverter where

Get a quote

PV String & Combiner Schedule (NEC 690) – Free Template

What is a PV string and where is it used? A PV string is a series connection of PV modules wired positive-to-negative so that voltage adds while current remains the same as a

Get a quote

Different voltages for strings and MPPT

If the MPPT is smart enough to figure out that more power is available at a notably lower voltage, then you''ll force the higher voltage string to operate near the lower voltage

Get a quote

Stringing PV inverter | AE 868: Commercial Solar Electric Systems

We discussed the effect of cell temperature on the I-V curve and the operating voltage and current in Lesson 2. Now it is time to apply this knowledge to calculate minimum and maximum

Get a quote

SUN5000-17-25K-MB0 Specs | HUAWEI Smart PV

*1.The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage inverter. *2.Any DC input voltage

Get a quote

Decoding Inverter Parameters (Part Ⅱ)

During power plant design, selecting inverters with appropriate MPPT voltage ranges based on local irradiance profiles and PV module characteristics or optimizing string

Get a quote

What is the input voltage range of a string inverter?

In this blog post, I''ll delve into the details of what the input voltage range of a string inverter is, why it matters, and how it impacts your solar power system.

Get a quote

SUN2000-100KTL-M1

*1 The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage inverter. 9 *2 Any DC input voltage beyond the operating voltage

Get a quote

Photonik | String Voltage Calculator

As the string voltages changes, the MPPT will continuously adjust and track the optimum string voltage. The MPPT operating voltage range for most string inverters is between 80V and

Get a quote

2023 Update: How to Calculate PV String Size

The primary goal of string sizing calculations is determining the minimum and maximum number of modules per string the inverter can handle.

Get a quote

2023 Update: How to Calculate PV String Size

The primary goal of string sizing calculations is determining the minimum and maximum number of modules per string the inverter can handle. Too many modules on a

Get a quote

Inverter lifetime, performance and reliability

In recent years, solar power has become very popular in the renewable energy industry. Solar systems have two main components: solar panels and solar

Get a quote

VOC, VMP, LSC, and matching your array to your inverter...

VMP at highest rated ambient temperature (since voltage drops as temperature increases) x number of panels in your string must be equal or greater to your inverter''s lowest

Get a quote

Microsoft Word

Conversely, a string inverter with shade-tolerant MPPT technology has a much better ability to operate at the true Vmp due to the extra range and flexibility of the string inverter''s MPPT

Get a quote

Solar Inverter String Design Calculations

The following article will help you calculate the maximum / minimum number of modules per series string when designing your PV system. And the inverter sizing comprises two parts,

Get a quote

String Sizing Guide: How Many Solar Panels Can I String Into My Inverter?

Learn how to calculate string size to optimize your inverter''s efficiency and get the most production out of your panels.

Get a quote

Application Note: SolarEdge Fixed String Voltage, Concept

The SolarEdge system maintains a fixed string voltage regardless of string characteristics and environmental conditions. This application note details the concept of operation of the

Get a quote

What is the String Solar Inverter?

Also, string solar inverters are easy to install, and the multiple presence of string solar inverters will support control and monitoring works on the entire solar system. What are

Get a quote

Guess what you want to know

-

Huijue inverter string voltage

Huijue inverter string voltage

-

36v inverter What is the minimum operating voltage

36v inverter What is the minimum operating voltage

-

Inverter operating voltage temperature coefficient

Inverter operating voltage temperature coefficient

-

Three-phase energy storage low voltage inverter

Three-phase energy storage low voltage inverter

-

Adjustable voltage inverter 12v to 220v

Adjustable voltage inverter 12v to 220v

-

72v inverter minimum voltage

72v inverter minimum voltage

-

Required AC voltage of inverter

Required AC voltage of inverter

-

Where can I buy a voltage inverter

Where can I buy a voltage inverter

-

High voltage inverter parameters

High voltage inverter parameters

-

Moldova low voltage inverter price

Moldova low voltage inverter price

Industrial & Commercial Energy Storage Market Growth

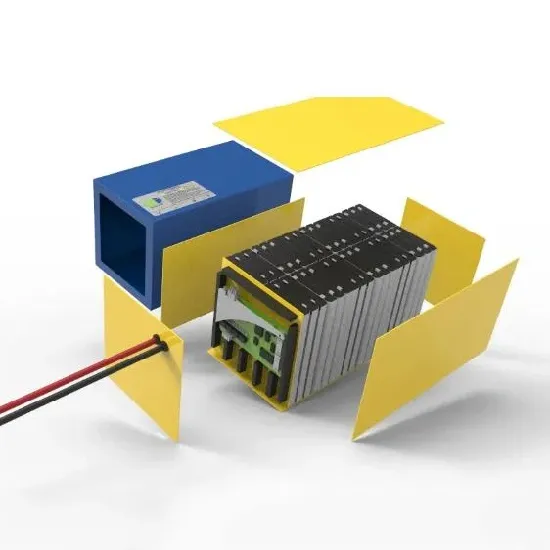

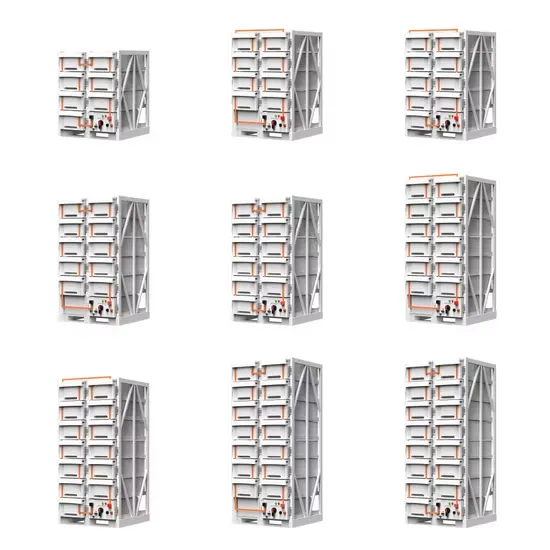

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.