The Battery Manufacturing Process

Battery manufacturing is a highly complex process that increasingly relies on advanced automation and digitalization. Gigafactories, at the forefront of innovation in the

Get a quote

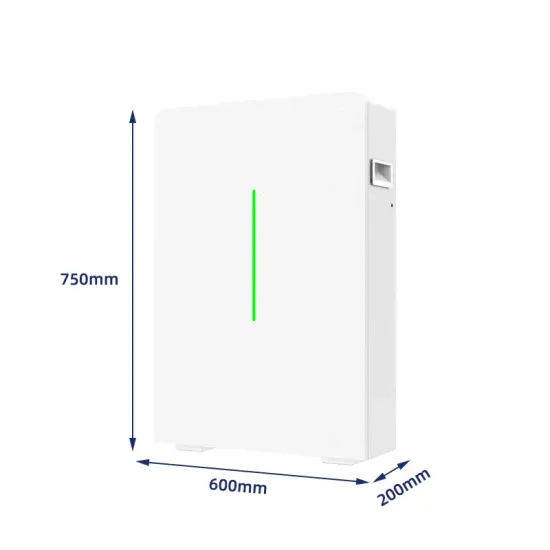

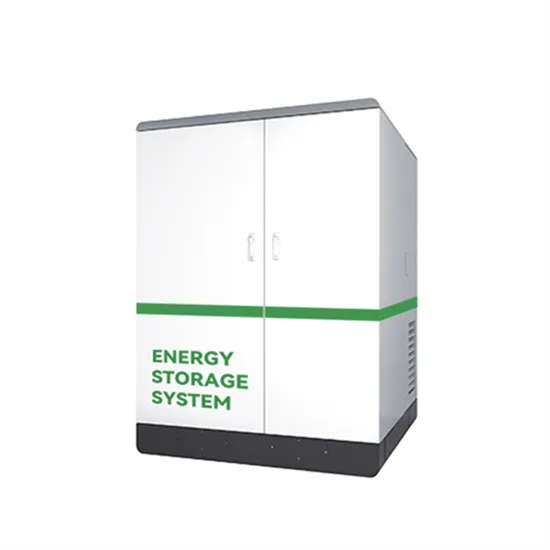

Forming Battery cabinet

Forming battery cabinets play a key role in the field of battery production and energy management. Its exquisite technology ensures the safe operation of the battery, and is widely

Get a quote

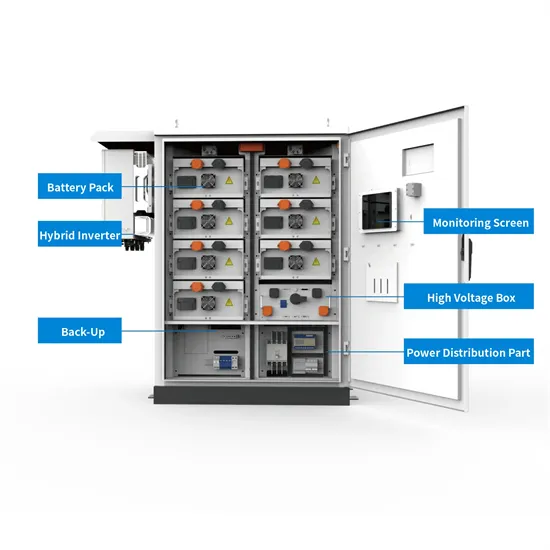

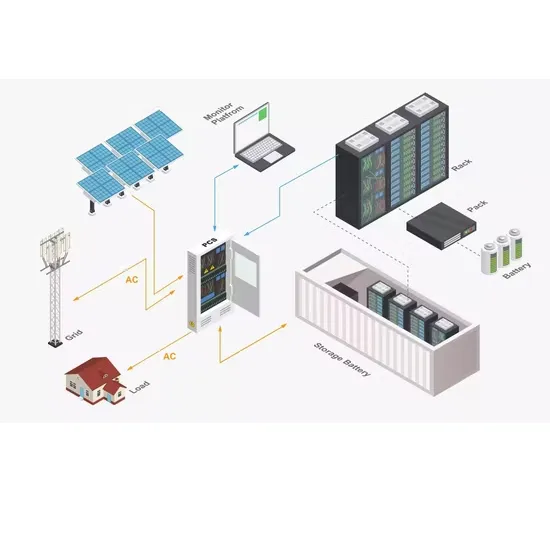

Energy storage cabinet production and processing

Breakthroughs have been made in a variety of energy storage technologies. Lithium-ion batterydevelopment trends continued toward greater capacities and longer

Get a quote

How AZE Systems Manufactures BESS Battery Energy Storage

Manufacturing a BESS cabinet requires a combination of advanced engineering, precise manufacturing, and rigorous testing. By following the steps outlined above, you can

Get a quote

Battery cells to high-voltage battery cabinets! Factory live production

🔋⚡Explore the core production line of the energy storage factory! 🏭From battery cell sorting, module welding to cabinet integration, the precision manufact...

Get a quote

Illustrated explanation of the battery cabinet production process

The total cost of a lithium-ion battery can be divided into roughly 75 % material costs and 25 % production costs. [5, 6] To facilitate meaningful innovations in battery production, a thorough

Get a quote

Battery cabinet production process English

The production of lithium battery modules, also known as Battery Packs, involves a meticulous and multi-step manufacturing process. This article outlines the key points of the lithium battery

Get a quote

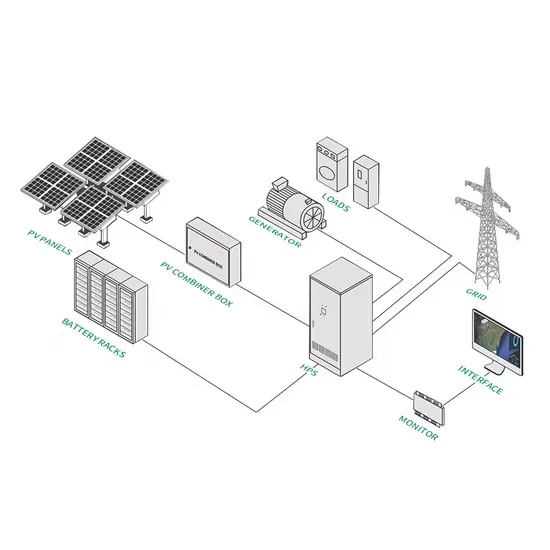

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get a quote

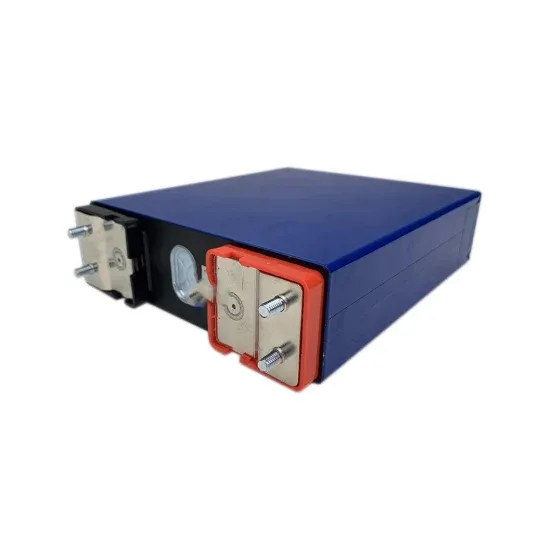

Battery cabinets are process materials

In the lithium battery manufacturing process, electrode manufacturing is the crucial initial step. This stage involves a series of intricate processes that transform raw materials into functional

Get a quote

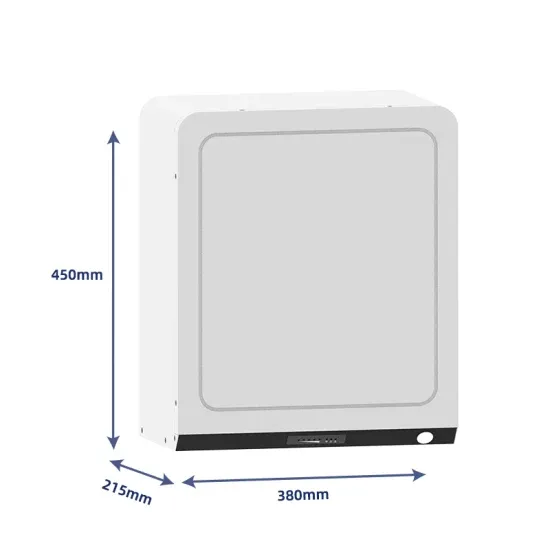

Complete Guide for Battery Enclosure

From battery box design, and fabrication, to quality inspection – our team handles every process for you. Our team will help you choose the right material, recommend the best

Get a quote

Battery cabinet production process English

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Get a quote

Battery cells to high-voltage battery cabinets! Factory live

🔋⚡Explore the core production line of the energy storage factory! 🏭From battery cell sorting, module welding to cabinet integration, the precision manufact...

Get a quote

Lithium battery energy storage cabinet processing

The Vertiv HPL lithium-ion battery cabinet is a safe,reliable,and cost-effective solution for high-power energy storage. It offers improved performance over traditional valve-regulated lead

Get a quote

Home energy storage cabinet production process

Battery manufacturer Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy storage cabinet assembly. The

Get a quote

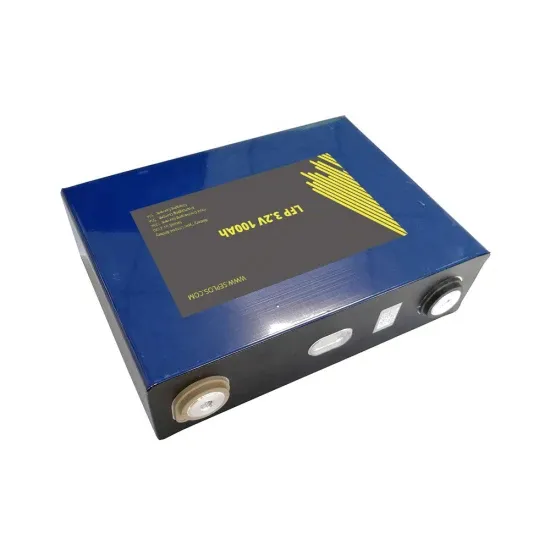

Lithium battery module design production process and

This article will introduce you to the characteristics, design and production process, key points, and development trend of lithium battery module structure

Get a quote

The EV Battery Manufacturing Process: Step by Step

The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Get a quote

Battery cabinets are process materials

In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting with a brief overview of existing

Get a quote

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Manufacturing a BESS cabinet requires a combination of advanced engineering, precise manufacturing, and rigorous testing. By following the steps outlined above, you can

Get a quote

Battery Manufacturing Process: Materials, Production

This guide covers the entire process, from material selection to the final product''s assembly and testing. Whether you''re a professional in the field

Get a quote

Battery cabinet production workshop process flow

Green manufacturing is a growing trend, and an effective layout design method for production lines can reduce resource wastage in processing. This study focuses on existing problems

Get a quote

Battery cabinet production workshop process flow

m-ion batteries so crucial in modern technology? The intricate production process involves more than 50 steps, from electrode sheet man facturing to cell synthesis and final packaging. This

Get a quote

Lithium battery temporary storage cabinet manufacturing process

Safely Store Batteries in Lithium-Ion Battery Justrite''''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9

Get a quote

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Get a quote

Battery Manufacturing Process: Materials, Production & Test

This guide covers the entire process, from material selection to the final product''s assembly and testing. Whether you''re a professional in the field or an enthusiast, this deep

Get a quote

Energy storage cabinet production and processing

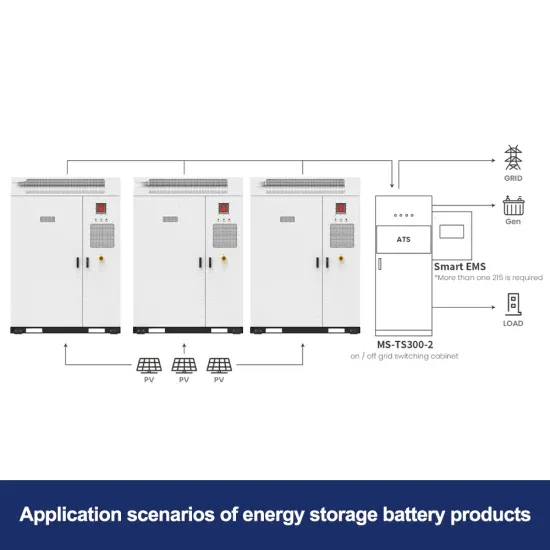

Lithium battery energy storage cabinets play a crucial role in this process by storing excess energy generated during peak production times and discharging it during The processing

Get a quote

Guess what you want to know

-

Ethiopia lithium battery station cabinet production plant

Ethiopia lithium battery station cabinet production plant

-

Mauritania outdoor communication battery cabinet processing

Mauritania outdoor communication battery cabinet processing

-

What are the battery cabinet production equipment

What are the battery cabinet production equipment

-

Cost price of energy storage cabinet battery production site

Cost price of energy storage cabinet battery production site

-

New energy battery energy storage cabinet processing process

New energy battery energy storage cabinet processing process

-

Battery cabinet system production

Battery cabinet system production

-

Authentic energy storage cabinet battery production base

Authentic energy storage cabinet battery production base

-

Energy Storage Cabinet Battery Production Market

Energy Storage Cabinet Battery Production Market

-

Does battery cabinet production consume energy

Does battery cabinet production consume energy

-

Battery Cabinet Production Notes

Battery Cabinet Production Notes

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.