Rapid safety screening realized by accelerating rate

This enables rapid safety screening and early-stage feedback for battery design, which can help accelerate the development of high-safety batteries.

Get a quote

Steps for Screening and Grading Cells in Battery Pack Production

During the production of battery packs, the screening and grading of cells are critical steps to ensure the performance and reliability of the battery pack. Here are the

Get a quote

Fault diagnosis and abnormality detection of lithium-ion battery packs

In short, the conventional fault diagnosis methods for lithium-ion battery packs, to the authors'' knowledge, are inefficient for detecting the faults and abnormalities and locating

Get a quote

Amazon : Lithium Battery Packs

2 Pack 12V 10Ah Lithium Ion LiFePO4 Deep Cycle Battery, 2000+ Cycles Rechargeable Battery for Solar/Wind Power, Scooters, Lighting, Power Wheels, Fish Finder Built-in 10A BMS 1K+

Get a quote

Consistency Screening of Lithium-Ion Batteries Based on

Lithium-ion batteries have the advantages of high energy density, low self-discharge rate and long service life, and are widely used in large mobile power supply and fixed energy

Get a quote

Using EIS Technology For Consistency Screening Of Lithium-Ion

By consistency screening before the batteries are shipped or assembled into modules and packs, the effective utilization of batteries can be improved, and the cycle life and

Get a quote

Social media resources | Civil Aviation Safety Authority

Don''t risk being delayed at check-in or security screening – pack right! Spare lithium batteries, like power banks, must only be packed in your carry-on, never in your checked baggage. Lithium

Get a quote

Using EIS Technology For Consistency Screening Of

By consistency screening before the batteries are shipped or assembled into modules and packs, the effective utilization of batteries can be

Get a quote

Lithium batteries with 100 watt hours or less in a device

Spare (uninstalled) lithium ion and lithium metal batteries, including power banks and cell phone battery charging cases, must be carried in carry-on baggage

Get a quote

Do You Need to Remove Chargers and Batteries at Airport

Yes, the Transportation Security Administration (TSA) requires travelers to take out all electronics with lithium ion batteries from carry-on bags when going through security

Get a quote

Consistency evaluation of Lithium-ion battery packs in electric

During the service process of lithium-ion battery packs, there is inconsistency among the cells in the pack, resulting in a significant decline in battery performance and

Get a quote

Lithium-ion Battery Safety

Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to many devices we

Get a quote

Using EIS For Consistency Screening Of Lithium-Ion Batteries

EIS-based consistency screening offers a robust solution to the "bucket effect" in LIB systems by evaluating both electronic and ionic resistances. The BIT6000 platform bridges

Get a quote

Fast screening of lithium-ion batteries for second use with pack

PDF | On May 1, 2023, Sijia Yang and others published Fast screening of lithium-ion batteries for second use with pack-level testing and machine learning | Find, read and cite all the...

Get a quote

Fast screening of lithium-ion batteries for second use with pack

Aiming at accelerating the progress of retired lithium-ion batteries for the second use, a fast and accurate screening approach based on pack-level testing is proposed for evaluating

Get a quote

A quick and intelligent screening method for large-scale retired

At the same time, a retired battery sorting architecture based on cloud-edge collaboration is presented, which offloads sorting tasks from the cloud to the edge side, and

Get a quote

Consistency Screening of Lithium-Ion Batteries Based on

For the consistency screening of lithium-ion batteries, the multi-parameter screening method is widely used due to its high accuracy. Clustering algorithms are commonly adopted in the

Get a quote

Advanced Screening for High-Power Lithium-Ion Batteries

The accurate and reliable screening of high-power lithium-ion battery cells before their integration into battery packs is not merely a quality control step; it is a fundamental requirement for

Get a quote

NASA Battery Research & Development Overview

Lynntech''s molten battery design is compatible with several cell chemistries including lithium-bismuth and lithium-selenium with excellent rechargeability and operate at

Get a quote

Research on a fast detection method of self-discharge of lithium battery

The existing self-discharge rate detection methods include the definition method, capacity retention method, and open-circuit voltage decay method [5]. The definition method is

Get a quote

Fast screening of lithium-ion batteries for second use

PDF | On May 1, 2023, Sijia Yang and others published Fast screening of lithium-ion batteries for second use with pack-level testing and machine learning |

Get a quote

An Internal Resistance Consistency Detection Approach for Lithium

Lithium-ion batteries (LIBs) are widely used in electric vehicles (EVs). The internal resistance consistency is essential to the performance and safety of LIB packs. To detect the consistency

Get a quote

The Fundamentals of Battery/Module Pack Test

Battery module and pack testing is critical for evaluating the battery''s condition and performance. This includes measuring the state of charge (SoC), depth of discharge (DoD), direct current

Get a quote

Research progress in the consistency screening of Li-ion

In this paper, the consistency screening of lithium ion batteries in recent years are reviewed. The concept and definition of the consistency of lithium ion batteries are explored.

Get a quote

Guess what you want to know

-

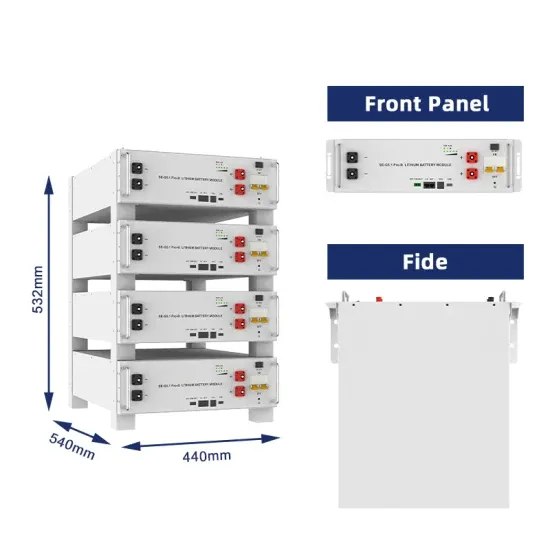

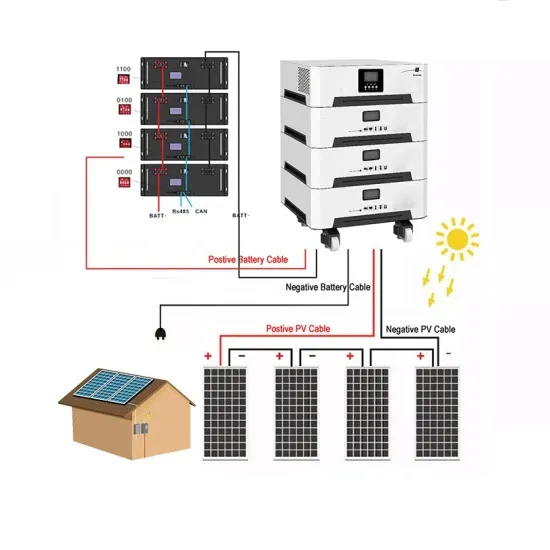

Nauru household lithium battery pack

Nauru household lithium battery pack

-

Standard lithium battery pack factory price in Sierra Leone

Standard lithium battery pack factory price in Sierra Leone

-

Turkey lithium iron phosphate battery pack

Turkey lithium iron phosphate battery pack

-

10kva lithium battery pack

10kva lithium battery pack

-

3-series lithium battery pack

3-series lithium battery pack

-

Assembling the components of a 60v 25a lithium battery pack

Assembling the components of a 60v 25a lithium battery pack

-

Lithium battery pack resistance difference has a great impact

Lithium battery pack resistance difference has a great impact

-

Israeli rechargeable lithium battery pack

Israeli rechargeable lithium battery pack

-

Lithium battery pack capacity decreases

Lithium battery pack capacity decreases

-

Pack lithium battery assembly price

Pack lithium battery assembly price

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.