Battery Cabinets for Uninterrupted Power Supply (UPS)

Battery Cabinets Through cutting-edge research and innovation, advanced engineered power products for backup battery cabinets have become

Get a quote

Battery Cabinet Dimensions Guide | HuiJue Group E-Site

Decoding the Geometry of Power Density Modern battery cabinet dimensions aren''t just about housing cells. The IEC 61427-1 standard now mandates 11% minimum airflow gaps – but did

Get a quote

Stationary UPS Sizing Calculations – Part Six

in Article " Stationary UPS Sizing Calculations -Part Four ", we explained Selection and sizing of UPS protective devices (CBs or Fuses). Also, in Article

Get a quote

6 Battery Energy Storage Systems — Lithium | UpCodes

The partitions separating the battery cabinets or open battery racks will help limit the spread of a fire from one battery or battery system to another. The partitions need to be floor to

Get a quote

battery cabinet : r/firealarms

I have seen battery cabinets anywhere from touching the floor to mounted above drop ceilings 12 feet up. Either there is not code that I have seen or many installers ignore it.

Get a quote

Cabinet and rack which one is better for Li-ion battery

Cabinets offer safety and protection for Li-ion battery packs, while racks provide scalability and flexibility. Choose based on space, cooling, and

Get a quote

Storage Requirements

Material Safety Data Sheets (MSDSs) contain general recommendations for the safe storage of a hazardous product. These recommendations provide a good starting point for deciding where

Get a quote

What is the height of the energy storage battery

The type of battery being employed plays a pivotal role in determining compartment height. For example, a compact lithium-ion battery

Get a quote

OSHA Requirements for Storage Over 5 Feet

OSHA Requirements for Grain Bins and Silos While there is no stacking height limit for grains, OSHA guidelines recommend certain workplace safety standards for

Get a quote

Spaces About Battery Systems | UpCodes

Battery stands may touch walls, but the shelf must maintain a free air space for at least 90% of its length. Additionally, it is important to consider extra space for equipment related to battery

Get a quote

What Is The Optimum Distance For Kitchen Cabinets

When designing a kitchen layout, one important factor to consider is the placement of the kitchen cabinets. While there are many possibilities for where

Get a quote

Lithium-ION Battery Storage Cabinets

Asecos safety storage cabinets are specifically designed to house lithium-ION batteries by providing a minimum of 90-minute protection against any fire or

Get a quote

480.9 Battery Locations.

Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

Get a quote

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Chargers need room to breathe and batteries need extra room above for maintenance (watering and testing). To calculate the minimum height of the cabinet, use the general formula above.

Get a quote

What is the height of the energy storage battery compartment?

The type of battery being employed plays a pivotal role in determining compartment height. For example, a compact lithium-ion battery bank may only require a

Get a quote

Eaton s lithium-ion UPS battery Q&A

This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium battery cabinets used with

Get a quote

Comprehensive Guide to Lithium Battery Cabinet Safety and

Fire Resistance and Construction A critical feature of any fireproof battery charging cabinet is its ability to withstand fire from both external and internal sources. Cabinets constructed with

Get a quote

Battery Enclosures, Cabinets & Racks

ICS battery enclosures, cabinets, and battery racks can be manufactured as standard or custom designed to accommodate any battery string configuration.

Get a quote

Complying With Fire Codes Governing Lithium-ion Battery Use

System -- The Vertiv HPL lithium-ion battery cabinet has successfully completed UL 9540A testing. The system provides safe, reliable and cost-efective high-power energy with improved

Get a quote

Battery Charging Room Regulations and Safety Information | BHS

The BHS Battery Room Survey is the perfect tool to help determine your battery room compliance with OSHA and other regulating bodies. It provides a checklist to use while evaluating a

Get a quote

New UL Standard Published: UL 1487, Battery Containment

In addition to these prevention strategies, battery containment products have emerged which are purpose-built for mitigation of thermal runaway hazards of lithium-ion batteries and battery

Get a quote

480.9 Battery Locations.

Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its

Get a quote

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get a quote

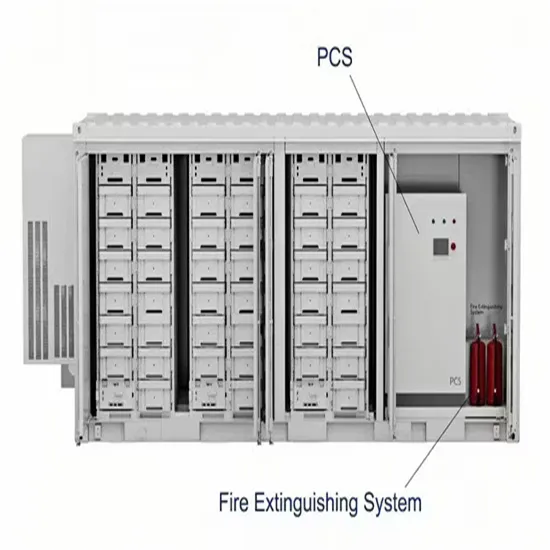

Battery Energy Storage Systems (BESS) FAQ Reference 8.23

All battery cells are inspected during manufacturing. The plant''s layered risk mitigation mechanisms are designed for the planned failure of any one battery cell. The

Get a quote

6 FAQs about [Is there any height limit for battery cabinets ]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Does your lift truck battery room comply with OSHA regulations?

To assure safe operating conditions in and around the lift truck battery room, it is important to comply with all relevant regulations. The BHS Battery Room Survey is the perfect tool to help determine your battery room compliance with OSHA and other regulating bodies.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

What is the BHS battery room survey?

The BHS Battery Room Survey is the perfect tool to help determine your battery room compliance with OSHA and other regulating bodies. It provides a checklist to use while evaluating a battery room for all required safety equipment, and it also lists related regulations. Download a copy of the Battery Room Survey.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What are the requirements for a battery layout?

The layout should accommodate: 2. Structural Requirements Floor loading capacity is critical - industrial batteries typically weigh 1500-3000 kg/m². For VLA (flooded) batteries, acid-resistant floor coatings compliant with AS/NZS 2430.3.2 are required.

Guess what you want to know

-

Battery cabinet height 30

Battery cabinet height 30

-

Paraguay s top ten photovoltaic communication battery cabinets

Paraguay s top ten photovoltaic communication battery cabinets

-

National Standard for Modular Battery Cabinets

National Standard for Modular Battery Cabinets

-

What brands of outdoor communication battery cabinets are there in Djibouti

What brands of outdoor communication battery cabinets are there in Djibouti

-

What types of single battery cabinets are included

What types of single battery cabinets are included

-

Lithium battery station cabinets connected in series

Lithium battery station cabinets connected in series

-

Which company in North Korea has the most battery cabinets

Which company in North Korea has the most battery cabinets

-

Notes on installing battery energy storage cabinets in communication base stations

Notes on installing battery energy storage cabinets in communication base stations

-

How to analyze the cost of lithium battery station cabinets

How to analyze the cost of lithium battery station cabinets

-

Bolivia has BESS outdoor battery cabinets

Bolivia has BESS outdoor battery cabinets

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.