How much does a flywheel energy storage system cost?

How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors,

Get a quote

BESS Costs Analysis: Understanding the True Costs of Battery Energy

Exencell, as a leader in the high-end energy storage battery market, has always been committed to providing clean and green energy to our global partners, continuously

Get a quote

Understanding the Cost of Flywheel Energy Storage Systems: A

These figures from Energy Storage Journal show why tech giants are spinning toward flywheels. The initial cost of flywheel energy storage systems becomes a smart

Get a quote

What is the price of flywheel energy storage? | NenPower

When considering the cost of flywheel energy storage relative to other storage technologies, such as lithium-ion batteries, the differences can be significant. Flywheel

Get a quote

Flywheel Battery Price: Cost Analysis and Market Trends for Energy

This article breaks down pricing factors, compares flywheel technology with traditional solutions, and reveals why sectors like data centers in the United States are

Get a quote

How much energy can a storage flywheel store

How long does a flywheel energy storage system last? Flywheel energy storage systems have a long working life if periodically maintained (>25 years). The cycle numbers of flywheel

Get a quote

Flywheel Battery Price: Cost Analysis and Market Trends for

This article breaks down pricing factors, compares flywheel technology with traditional solutions, and reveals why sectors like data centers in the United States are

Get a quote

How much does a flywheel energy storage device cost

The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative

Get a quote

Flywheel Energy Storage Costs: Breaking Down the Economics

Breaking down a typical $1.2 million/MW flywheel installation: The good news? Material science breakthroughs are driving down the most expensive components. Take carbon fiber prices -

Get a quote

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

Unlike battery systems needing more TLC than a newborn, flywheel O&M costs average $8/kW-year versus $25+ for lithium-ion. That''s like comparing a Honda''s maintenance

Get a quote

RotorVault Energy Storage Cost Analysis and Flywheel Price

Explore RotorVault''s cost-competitiveness and scalability. A comparative cost analysis with Battery and Flywheel Energy Storage Systems.

Get a quote

Flywheel energy storage operating costs

The amortized capital costs are $130.26 and $92.01/kW-year for composite and steel rotor FESSs, respectively. The corresponding LCOSs are $189.94 and $146.41/MWh, respectively.

Get a quote

How much does a flywheel energy storage system cost?

How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors, including size, design, and installation

Get a quote

Approximate cost of flywheel energy storage

How much does a flywheel energy storage system cost? The amortized capital costs are $130.26 and $92.01/kW-year for composite and steel rotor FESSs, respectively. The corresponding

Get a quote

Flywheel vs Battery Energy Storage Cost Analysis

Cost and Lifecycle Cost Comparison: This comparison simplifies the complexities of energy storage system economics. Actual costs and lifespans can vary significantly based

Get a quote

Energy and environmental footprints of flywheels for utility-scale

The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

Get a quote

The development of a techno-economic model for the

The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a

Get a quote

Flywheel energy storage operating costs

How much does a flywheel energy storage system cost? The amortized capital costs are $130.26 and $92.01/kW-year for composite and steel rotor FESSs, respectively. The corresponding

Get a quote

World''s largest flywheel energy storage system with

China''s massive 30-megawatt (MW) flywheel energy storage plant, the Dinglun power station, is now connected to the grid, making it the

Get a quote

What is the price of flywheel energy storage?

When considering the cost of flywheel energy storage relative to other storage technologies, such as lithium-ion batteries, the differences can

Get a quote

Flywheel energy storage system price per KW

The total cost can be broken down into the following categories: (1) ESS cost, which is actually the overnight capital cost of the storage unit and can be divided into two parts, namely cost per

Get a quote

Megawatt Flywheel Energy Storage Price: What You Need to

Ever wondered how industries store enough energy to power a small town during a blackout? Enter megawatt flywheel energy storage – the silent workhorse of the power world. As

Get a quote

Flywheel Energy Storage | Energy Engineering and Advisory

How Does Flywheel Energy Storage Work? The flywheel energy storage system is useful in converting mechanical energy to electric energy and back again with the help of fast

Get a quote

Fact Sheet | Energy Storage (2019) | White Papers | EESI

Much of the price decrease is due to the falling costs of lithium-ion batteries; from 2010 to 2016 battery costs for electric vehicles (similar to the technology used for storage) fell

Get a quote

The Amber Kinetics Energy Storage System

Amber Kinetics pioneered long duration flywheel energy storage and is now revolutionizing the field by providing high speed, rapid response and near

Get a quote

DOE ESHB Chapter 25: Energy Storage System Pricing

This chapter summarizes energy storage capital costs that were obtained from industry pricing surveys. The survey methodology breaks down the cost of an energy storage system into the

Get a quote

ESS 2012 Peer Review

Established a technology licensing & flywheel development partnership with LLNL; Amber Kinetics identified new material & lower-cost rotor designs for commercialization

Get a quote

6 FAQs about [How much does 1 MW of flywheel energy storage cost ]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

How much does a flywheel power converter cost?

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

What is the largest flywheel energy storage?

The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration . Utility-scale flywheel storage is typically used for frequency regulation to maintain grid frequency by matching electricity supply and demand for a short period, usually 15 min , .

Guess what you want to know

-

How much does one MW of battery energy storage cost per kilowatt-hour

How much does one MW of battery energy storage cost per kilowatt-hour

-

How much does it cost to design an energy storage system

How much does it cost to design an energy storage system

-

How much does lithium battery for energy storage cost in Armenia

How much does lithium battery for energy storage cost in Armenia

-

How much does it cost to build a new energy storage power station

How much does it cost to build a new energy storage power station

-

How much does energy storage battery cost in Paraguay

How much does energy storage battery cost in Paraguay

-

How much does the Dutch energy storage power supply cost

How much does the Dutch energy storage power supply cost

-

How much does the Venezuelan energy storage equipment box cost

How much does the Venezuelan energy storage equipment box cost

-

How much does it cost to manufacture energy storage vehicles in Poland

How much does it cost to manufacture energy storage vehicles in Poland

-

How much does a photovoltaic 40-degree energy storage cabinet cost

How much does a photovoltaic 40-degree energy storage cabinet cost

-

How much does a battery energy storage cabinet cost in Latvia

How much does a battery energy storage cabinet cost in Latvia

Industrial & Commercial Energy Storage Market Growth

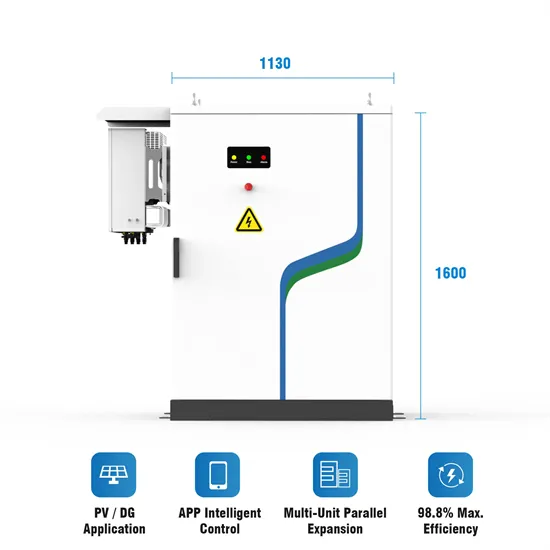

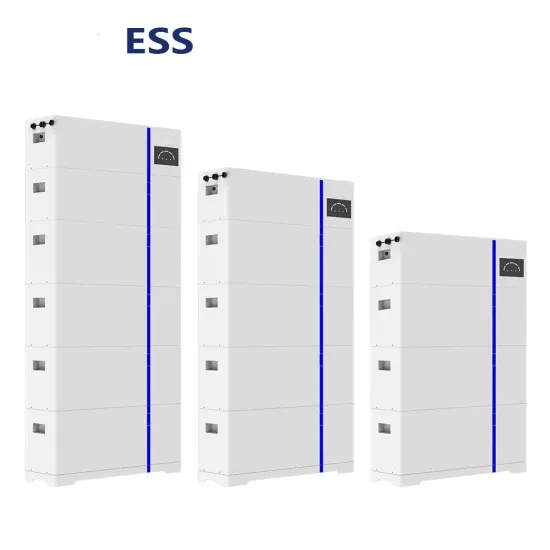

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.