Why BMS is not required for lead acid battery?

BMSes generally are not used with lead acid because they can be "safely" over charged. Over charging will drive off some water and that will need to be replaced. Do you

Get a quote

Can you use a BMS on lead acid batteries?

The lead-acid battery system would need its own charger and/or charge controller but would not need a BMS. What kills a lead acid battery? While overcharging a lead-acid

Get a quote

Can you mix lithium and lead-acid batteries on an

There are pros and cons associated with the two main battery chemistries used in solar + storage projects. Lead-acid batteries have been

Get a quote

Reviving 0v and Low Voltage Batteries and Cells

Lead acid cells and battery packs can be recovered from 0V and used with almost the same performance as before. However, lithium-ion cells

Get a quote

4. System Design

The Lynx Smart BMS can only be used with the Victron Energy Lithium Smart Batteries, while the Lynx Shunt VE.Can is suitable for all other batteries. Then, single, multiple or a combination of

Get a quote

Battery Compatibility

The information above refers to manufactured battery packs with a supplied BMS. Besides those, there are also companies selling seperate BMS-es intended to be used with

Get a quote

Mixing lead acid and lithium

I had my BMS activating load disconnect once due to high current surge but inverters didn''t go down due to the presence of Lead Acid bank :) I am prepared to change the MPPT profile -

Get a quote

The most complete analysis of bms for lead acid battery

The key component of bms for lead acid battery is the intelligent battery sensor (IBS), which can measure the terminal voltage, current and temperature of the

Get a quote

Lead-Acid Battery Management Systems

Lead-acid batteries, under the control of a BMS, can be used to store energy during off-peak hours when electricity rates are lower and then discharge during peak periods to meet

Get a quote

The most complete analysis of bms for lead acid battery

The key component of bms for lead acid battery is the intelligent battery sensor (IBS), which can measure the terminal voltage, current and temperature of the battery and calculate the status

Get a quote

A Complete Guide to Lead Acid BMS

Extended Battery Life: By preventing overcharging and deep discharges, a BMS can significantly extend the life of a lead-acid battery. This is especially important in

Get a quote

Do Lead Acid Batteries Need A Battery Management

Yes, a Battery Management System is really useful, despite the fact that it is a lead-acid battery. Not quite as common in the case of lead-acid

Get a quote

Lead-Acid Battery Management Systems

Lead-acid batteries, under the control of a BMS, can be used to store energy during off-peak hours when electricity rates are lower and then discharge

Get a quote

Do I Need a Battery Management System for Lead Acid Battery?

The lead-acid battery system would need its own charger and/or charge controller but would not need a BMS. What kills a lead acid battery? While overcharging a lead-acid

Get a quote

Lithium-Ion vs. Lead-Acid Batteries: How BMS Requirements

Lead-acid batteries, while more robust and cost-effective, require different management strategies to prevent sulfation and stratification. This post will explore these

Get a quote

Why Lead-Acid Batteries Need Battery Monitoring

To overcome these challenges, integrating a Battery Monitoring System (BMS) is essential. This article explores why lead-acid batteries need

Get a quote

Do Lead Acid Batteries Need A Battery Management System?

Yes, a Battery Management System is really useful, despite the fact that it is a lead-acid battery. Not quite as common in the case of lead-acid batteries as for lithium-ion, the

Get a quote

Do I Need a Battery Management System for Lead Acid Battery?

Do you need a BMS on your lead-acid battery? That depends on several factors. If you are using your lead-acid battery in a high-demand application like an electric car or

Get a quote

Safeguarding Lead-Acid Batteries: Understanding

Lead-acid batteries, as a well-established energy storage technology, are widely used in data centers, telecommunications, and other fields. During practical

Get a quote

BMS For Lead-acid Battery

The BMS battery management system can monitor battery leakage, battery internal open circuit status, battery thermal runaway, and other parameters in real-time, and escort battery safety in

Get a quote

The Ultimate Guide to Lead Acid Battery BMS: Everything You

Yes, lead-acid battery BMS systems are intended to work with a variety of lead-acid batteries, including flat and tubular ones. However, it is critical to verify that the BMS is

Get a quote

best battery for 40 hp outboard motor

Typically, lead-acid batteries last around 3-5 years, while lithium-ion batteries can last up to 10 years or more. Choosing a battery with a longer lifespan can save money and

Get a quote

Guide to Upgrading Your Golf Cart to Lithium Batteries

What is involved in upgrading your golf cart to lithium batteries? Upgrading your golf cart to lithium batteries involves selecting the right battery type, ensuring compatibility with

Get a quote

The Ultimate Guide to Lead Acid Battery BMS:

Yes, lead-acid battery BMS systems are intended to work with a variety of lead-acid batteries, including flat and tubular ones. However, it is

Get a quote

Use a 24V LifePo battery in a UPS designed for lead acid batteries?

I have an existing APC 1500 UPS, designed for use with 24v lead acid batteries and want to know if it would be possible to replace my dead lead acid battery with a 24V

Get a quote

Can I Replace My Lead-Acid Battery with a Lithium One?

Maintenance and Long-Term Use One of the standout benefits of switching to a LiFePO4 lithium battery is the reduced need for maintenance.

Get a quote

Battery Isolator with Lithium and Lead Acid Connections

The voltage difference of the two batteries, combined with the internal BMS within the lithium and lack of BMS within the lead-acid can create

Get a quote

Can You Use a Regular SLA Charger to Charge a GMA Lithium Battery?

No, you should not use a regular SLA (Sealed Lead Acid) charger to charge a GMA lithium battery. While it might physically connect and even begin to charge, doing so can risk

Get a quote

6 FAQs about [Can lead-acid batteries be used in BMS ]

What is a lead acid battery BMS?

Lead-acid battery BMS has shown versatility and adaptability in a variety of applications, including renewable energy storage and electric forklifts. In conclusion, the Lead Acid Battery BMS is an important technology that improves the performance, safety, and durability of lead acid batteries in a variety of applications.

Can a lead-acid battery BMS work with a tubular battery?

Yes, lead-acid battery BMS systems are intended to work with a variety of lead-acid batteries, including flat and tubular ones. However, it is critical to verify that the BMS is precisely tailored for the battery utilised in the application.

Can I add a BMS to a lead-acid battery pack?

I assembled a lead-acid battery pack with six batteries. Is it possible to add a BMS for a lead-acid battery? Yes. A BMS is a Battery Management (or monitoring) system. As a general rule they are a good thing.

What are the main functions of a lead-acid battery (BMS)?

The main functions of a lead-acid battery (BMS) are Track the battery’s state of charge (SOC), voltage, current, temperature, and other metrics. Keep the battery from running beyond its safe operating range. Balance the cells in the battery pack so that they all have the same voltage.

Is lead-acid battery BMS technology a promising future?

Related: Understanding the Significance of PAM/NAM Ratio in Lead Acid Batteries Lead-acid battery BMS technology appears to have a promising future. With continued research and development, we may expect increasingly smarter systems, more efficiency, and better integration.

What is battery management system for lead acid batteries?

Battery Management System for Lead Acid Batteries is a one-of-a-kind solution that equalises two or more lead acid batteries in a battery bank linked in series, eliminating imbalance in the form of uneven voltage that occurs over time when charged and discharged in an inverter/UPS, etc.

Guess what you want to know

-

Can lead-acid batteries be used for household energy storage

Can lead-acid batteries be used for household energy storage

-

What are the outdoor energy storage lead-acid batteries

What are the outdoor energy storage lead-acid batteries

-

Capacity of base station lead-acid batteries

Capacity of base station lead-acid batteries

-

Photovoltaic energy storage batteries can be used for home use

Photovoltaic energy storage batteries can be used for home use

-

Can zinc-manganese batteries be used for energy storage

Can zinc-manganese batteries be used for energy storage

-

Energy Storage Batteries and Lead-Acid Batteries

Energy Storage Batteries and Lead-Acid Batteries

-

Lithium batteries require BMS

Lithium batteries require BMS

-

Lithium batteries must be added with BMS

Lithium batteries must be added with BMS

-

What can energy storage batteries be used for

What can energy storage batteries be used for

-

Top 10 Energy Storage Lead-Acid Batteries

Top 10 Energy Storage Lead-Acid Batteries

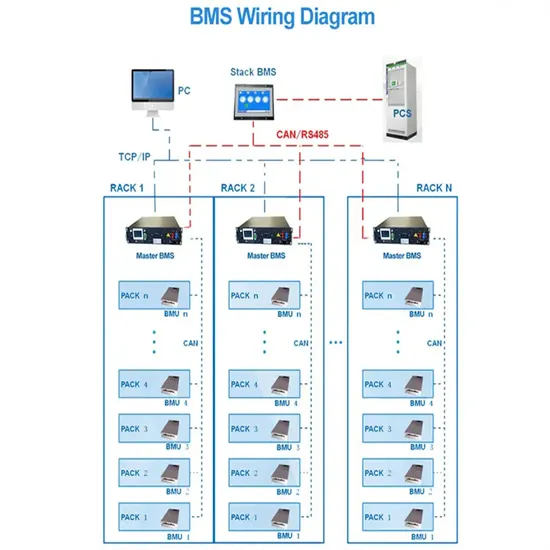

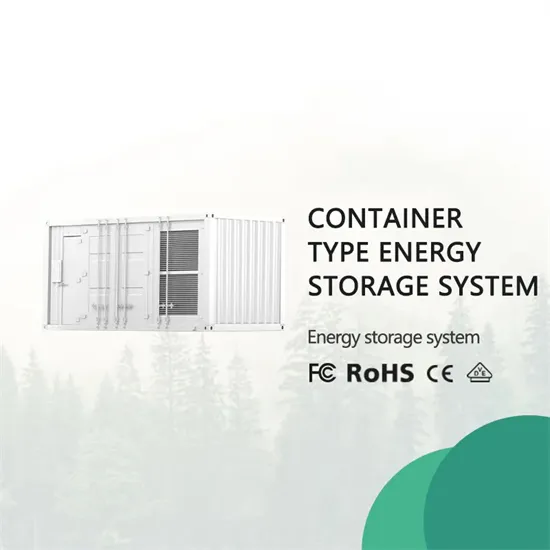

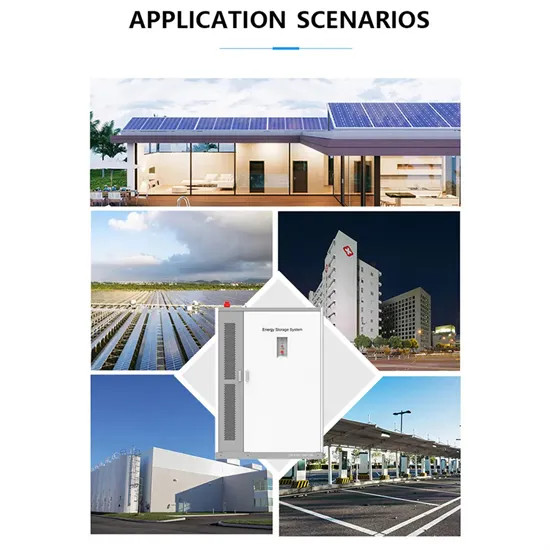

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

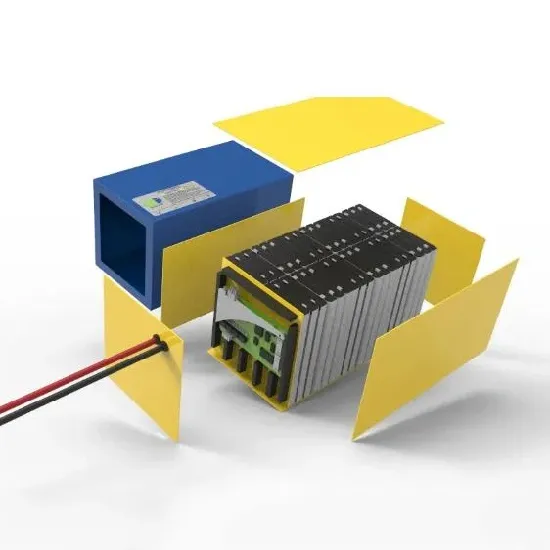

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.