Battery Cabinet

To check for inadvertent grounding of the battery, use a digital multi-meter set to the DC Volts scale to measure the voltage between any battery terminal and either the cabinet framework

Get a quote

BC Series UPS Battery Cabinets

To ensure the safe and proper use of ZincFive BC Series UPS Battery Cabinet, the following symbols are used throughout this manual or on the equipment. Operators, buyers, and

Get a quote

UPS Battery Cabinets

The cabinet should be set in place after the holes are marked and drilled, and bolts are set in the correct pattern. Set and bolt one cabinet at a time to allow side access as needed.

Get a quote

DESIGN FOR SAFE AND RELIABLE ELECTRICAL

Unlike the short circuit current generated by the AC sources, generally predictable, the short circuit current generated by the battery is variable and not easily predictable. With an

Get a quote

Eaton-Battery-Handbook-BAT11LTA.PDF

Full-float operation – Operation of a DC system with the battery, battery charger and load connected in parallel, with the battery charger supplying the normal DC load plus any self

Get a quote

UBC87 Battery Cabinet Installation, Operation,

Install the main POS and NEG cables from the output circuit breaker to the correct battery posts on the designated battery units shown in the provided battery system schematic.

Get a quote

How to manage power settings on Windows 11

In this guide, we''ll show you the steps to configure the Windows 11 power settings to increase battery life on your laptop or keep the power usage

Get a quote

Eaton 93PM Integrated Battery Cabinet-Large and Large

The battery wiring used between the battery and the UPS for standalone installations should be a maximum of 20 meters (65 feet) with a voltage drop of less than 1% of nominal DC voltage at

Get a quote

EnerSys NexSys+ Battery Charger Owner''s Manual

Charging current declines automatically as battery voltage rises during the charge. As the battery charges, the graphical display will output various charge parameters including the percentage

Get a quote

Generac PWRcell

The battery can be used for grid- connected solar applications, such as self-supply, rate arbitrage, and clean backup power. The chart below describes the color and strobing interval of the LED

Get a quote

PCS Integration in Enphase Storage System

PCS Integration uses smart real-time current sensing to monitor and limit the current fed back to the main panel, thereby eliminating the need for a Main Panel upgrade. PCS Integration

Get a quote

Galaxy Lithium-ion Battery Cabinet

Manually set the battery breaker of each individual battery cabinet to the OFF (open) position to disconnect the battery power from the UPS. NOTE: The system BMS and rack BMS will still

Get a quote

Microsoft Word

Consult the battery manufacturer''s battery operation and maintenance manual for complete instructions. These battery systems are Hi-Pot tested to UL 1778 standards at the factory prior

Get a quote

User''s Guide UPS 20

A parallel UPS system means the linking together of two or more UPS units in parallel so that in the unlikely event one fails the other can automatically take up the load. Traditionally a parallel

Get a quote

UBC80 Battery Cabinet Installation, Operation,

Isolates the battery cabinet from the UPS Divides the 480VDC battery string into two (2) battery strings of 240VDC each. Unlocks the battery cabinet doors to allow access to the cabinet

Get a quote

NV14 Energy Storage System USER MANUAL

Do not connect or disconnect wires to the NV14 Energy Storage System when current from the modules or an external source is present. This is a multifunctional inverter, combining

Get a quote

TechnologyCo.,LTD ESS-GRIDCabinetSeries UserManual

The customer does not set the battery operation management parameters correctly or improper maintenance, resulting in frequent battery discharge, the customer expands the capacity or

Get a quote

Vertiv Liebert® APM2 Modular EBC User Manual

Save these instructions This manual contains important instructions that should be followed during installation of VertivTM Liebert® APM2 Modular External Battery Cabinet (EBC) and

Get a quote

Used Anchor Battery Cabinet Price for sale. Chaparral

Search for used anchor battery cabinet price. Find Chaparral, Chris-Craft, Rinker, Monterey, Beneteau, Winnebago, Advantech, and Anchor for sale on Machinio.

Get a quote

How to adjust the voltage and current of the battery cabinet

To charge the battery, the buck converter is enabled while the first-stage voltage Op Amps and current-sense INA are used to measure battery voltage and charging current of the battery cell

Get a quote

USER MANUAL BATTERY CABINET

Cable sizing from the battery cabinet to the remainder of the ESS is dependent on multiple factors including the system maximum current draw, distance between the battery cabinet and ESS,

Get a quote

6 FAQs about [Battery cabinet current setting]

How do I install a battery cabinet?

Install plastic covers onto batteries. Some covers may need to be notched for locations with bus bars and/or cables in upward orientation. Ground the battery cabinet to the main building ground. A ground stud inside the cabinet is provided for this. Refer to the UPS or charger manual for start up and operation of system.

Where is the battery cabinet located?

The battery cabinet may be located to either the right or left of the UPS cabinet. The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21.

How do you ground a battery cabinet?

Ground the battery cabinet to the main building ground. A ground stud inside the cabinet is provided for this. Refer to the UPS or charger manual for start up and operation of system. 8. SYSTEM MAINTENANCE

What should I know before installing a battery cabinet system?

Never enclose batteries or battery cabinets in a sealed air tight room. All jewelry and watches must be removed prior to installing or servicing this system. Do not smoke or present flame near or around any battery cabinet system. Never leave a panel off or door open and unattended. 3. INSPECTION UPON RECEIPT OF GOODS

Where do I install a line-up and match Battery Cabinet?

Line-up-and-match battery cabinets are installed adjacent to the UPS. The recommended installation location is on the right side of the UPS cabinet as viewed from the front of the cabinet. See Figure 3 for line-up-and-match configuration views. Figure 3. Eaton 93PM 100 kW UPS and Two 93PM Integrated Battery Cabinets

Where is the UPS battery cabinet located?

The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21. If line-up-and-match installation, remove the rectangular knockout on the bottom front side of the UPS and the IBC (see Figure 15).

Guess what you want to know

-

How much current does a 9v battery in an energy storage cabinet have in amperes

How much current does a 9v battery in an energy storage cabinet have in amperes

-

Total current of new energy battery cabinet

Total current of new energy battery cabinet

-

Calculation of current and voltage of lithium battery station cabinet

Calculation of current and voltage of lithium battery station cabinet

-

How much current does a 100 kWh battery cabinet draw

How much current does a 100 kWh battery cabinet draw

-

How to measure the output current and voltage of the battery cabinet

How to measure the output current and voltage of the battery cabinet

-

What is the voltage and current of the energy storage cabinet battery

What is the voltage and current of the energy storage cabinet battery

-

How much current does the energy storage cabinet battery have

How much current does the energy storage cabinet battery have

-

Does the current of the energy storage cabinet battery decrease as it is used

Does the current of the energy storage cabinet battery decrease as it is used

-

Rwanda lithium battery site cabinet charging current

Rwanda lithium battery site cabinet charging current

-

What should the battery cabinet current be

What should the battery cabinet current be

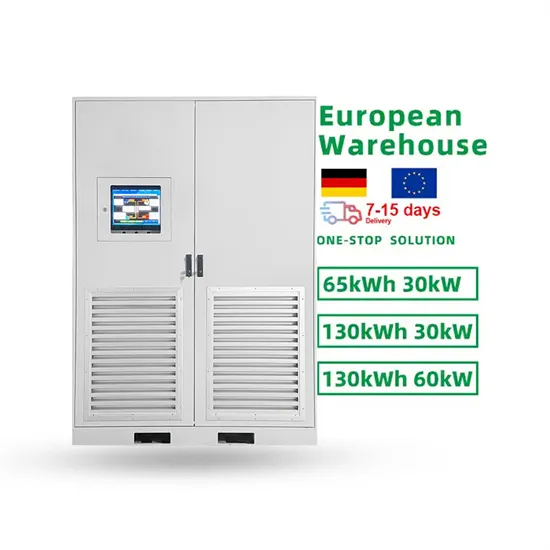

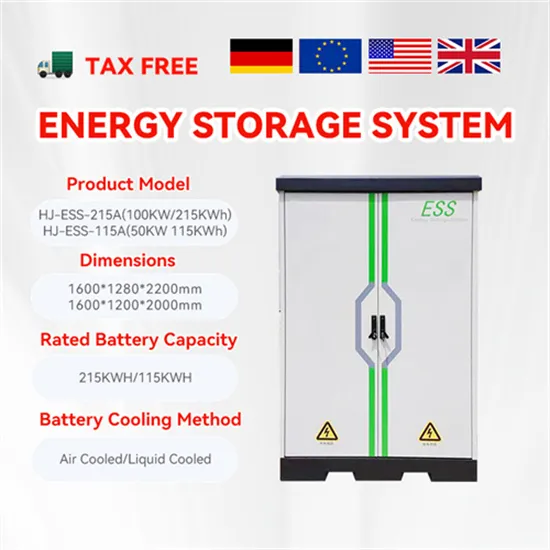

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.