Using liquid air for grid-scale energy storage

Liquid air energy storage could be the lowest-cost solution for ensuring a reliable power supply on a future grid dominated by carbon-free yet

Get a quote

Difference Between Liquid and Air Cooling for Energy Storage

Discover the key differences between liquid and air cooling for energy storage systems. Learn how each method impacts battery performance, efficiency, and lifespan to

Get a quote

Liquid air energy storage systems: A review

Liquid Air Energy Storage (LAES) systems are thermal energy storage systems which take electrical and thermal energy as inputs, create a thermal energy reservoir, and

Get a quote

Difference Between Liquid and Air Cooling for Energy

Discover the key differences between liquid and air cooling for energy storage systems. Learn how each method impacts battery

Get a quote

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which

Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Get a quote

Eight Key Differences Between Air Cooling and Liquid

Currently, air cooling and liquid cooling are two widely used thermal management methods in energy storage systems. This article provides a detailed

Get a quote

Comparison of liquid cooling and air cooling energy storage costs

Is liquid cooling better than air cooled data center? It demonstrates that for like densities (10kW/rack), the data center cost of an air-cooled and liquid-cooled data center are roughly

Get a quote

Explainer: does liquid air energy storage hold promise?

Liquid air energy storage (LAES) is a technology that converts electricity into liquid air by cleaning, cooling, and compressing air until it reaches a liquid state.

Get a quote

comparison between liquid cooling and air cooling for energy storage

When you''re looking for the latest and most efficient comparison between liquid cooling and air cooling for energy storage for your PV project, our website offers a comprehensive selection of

Get a quote

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which Cooling

Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Get a quote

Eight major differences between air cooling and liquid cooling in

Air cooling and liquid cooling are two commonly used heat dissipation methods in energy storage systems. When choosing a heat dissipation method, factors such as the actual power of the

Get a quote

CHOOSING BETWEEN AIR-COOLED AND LIQUID

When it comes to energy storage, selecting the appropriate cooling method is crucial for efficient and reliable operation. Two commonly used

Get a quote

Air Cooling vs. Liquid Cooling: The Ultimate Energy

Energy Storage Systems (ESS) are essential for a variety of applications and require efficient cooling to function optimally. This article sets

Get a quote

Liquid vs Air Cooling System in BESS – Complete Guide

2 days ago· Liquid vs Air Cooling System in BESS – Complete Guide: Battery Energy Storage Systems (BESS) are transforming how we store and manage renewable energy. But one often

Get a quote

Liquid Cooling Containerized C&I Storage Reshapes Renewable Energy

The global energy storage landscape is undergoing a transformative shift as liquid cooling containerized solutions emerge as the new standard for commercial and industrial

Get a quote

Eight Key Differences Between Air Cooling and Liquid Cooling in Energy

Currently, air cooling and liquid cooling are two widely used thermal management methods in energy storage systems. This article provides a detailed comparison of the differences

Get a quote

Liquid vs Air Cooling System in BESS – Complete Guide

2 days ago· Liquid vs Air Cooling System in BESS – Complete Guide: Battery Energy Storage Systems (BESS) are transforming how we store and manage renewable energy. But one often

Get a quote

Air-cooled Chiller vs. Water-cooled Chiller – White

Explore the strategic benefits of air-cooled vs. water-cooled chillers in optimizing energy efficiency, installation, and environmental impact for

Get a quote

Battery Storage Cooling Methods: Air vs Liquid Cooling

2 days ago· As battery energy storage systems grow in scale, thermal management becomes a defining factor for performance, safety, and lifespan. While people often focus on cell

Get a quote

Air Cooling vs. Liquid Cooling of BESS: Which One Should You

Choosing between air cooling and liquid cooling for your BESS depends on various factors, including budget, performance requirements, maintenance capabilities, and

Get a quote

Eight major differences between air cooling and liquid cooling in

Air cooling and liquid cooling are two commonly used heat dissipation methods in energy storage systems, and they each have their own advantages and disadvantages.

Get a quote

Optimizing thermal performance in air-cooled Li-ion battery

Air cooling techniques using MVGs inside the input duct channel have shown significant thermal performance in terms of temperature reduction in battery thermal

Get a quote

Air Cooling vs. Liquid Cooling of BESS: Which One Should You

Environmental Impact The choice between air cooling and liquid cooling can also be influenced by environmental factors. Liquid cooling systems, while more efficient, may

Get a quote

Liquid air energy storage (LAES) – Systematic review of two

Electrical energy storage systems are becoming increasingly important in balancing and optimizing grid efficiency due to the growing penetration of renewable energy

Get a quote

CHOOSING BETWEEN AIR-COOLED AND LIQUID-COOLED ENERGY STORAGE

When it comes to energy storage, selecting the appropriate cooling method is crucial for efficient and reliable operation. Two commonly used options are air-cooled and

Get a quote

Air Cooling vs. Liquid Cooling: The Ultimate Energy Storage

Energy Storage Systems (ESS) are essential for a variety of applications and require efficient cooling to function optimally. This article sets out to compare air cooling and

Get a quote

Liquid cooling vs air cooling

Liquid cooling technology refers to the method of cooling by liquid contact with heat source. According to the different contact heat transfer methods between cooling liquid

Get a quote

Battery Cooling Tech Explained: Liquid vs Air Cooling

Air cooling sis suitable for low-C-rate or cost-sensitive systems, while liquid cooling is for high-performance EVs and utility-scale storage

Get a quote

6 FAQs about [Comparison of liquid cooling and air cooling for energy storage]

Are air cooling systems better than liquid cooling systems?

Air cooling systems, with their simpler design, are generally easier to maintain and have a lower risk of failure. Liquid cooling systems, while more efficient, require more maintenance and have a higher risk of leaks or other issues. Consider the available resources and expertise when choosing between these systems.

What is the difference between air cooling and liquid cooling?

Air cooling offers simplicity, cost-effectiveness, and reliability, making it suitable for smaller or less demanding applications. Liquid cooling, with its superior efficiency, compact design, and quieter operation, is better suited for high-capacity or high-performance systems.

How a liquid cooled data center is better than air cooled?

The liquid-cooled systems can reduce the overall data center consumption up to 30% in comparison with air cooled data centers , but they are expensive and presents fluid leakage risks. So far, the cooling technology with the higher heat removal capacity is thermosyphon loop.

Which cooling method is best for battery energy storage systems?

When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling and liquid cooling. Each method has its own strengths and weaknesses, making the choice between the two a critical decision for anyone involved in energy storage solutions.

Does the temperature difference between air cooling and liquid cooling affect power consumption?

However, the temperature of the hottest cell in the liquid-cooled module is lower than the air-cooled module within the investigated range of power consumption. The temperature difference of the hottest cell between air cooling and liquid cooling reduces with an increase in power consumption.

What is the difference between free cooling and liquid cooled technology?

The free cooling technology consists of using the natural fluid to cool data centers. The liquid cooled technology is useful when the data centers have a high-power density. The two-phase flow technology consists of using a refrigerant capable of removing dissipated heat by racks and rejecting to the outside environment.

Guess what you want to know

-

Which is better for energy storage cabinets air cooling or liquid cooling

Which is better for energy storage cabinets air cooling or liquid cooling

-

The difference between liquid cooling and air cooling energy storage

The difference between liquid cooling and air cooling energy storage

-

What are liquid cooling and air cooling for energy storage cabinets

What are liquid cooling and air cooling for energy storage cabinets

-

Energy storage cabinet liquid cooling design cost

Energy storage cabinet liquid cooling design cost

-

Fiji liquid cooling energy storage container supplier

Fiji liquid cooling energy storage container supplier

-

Liquid cooling shunt design for energy storage system

Liquid cooling shunt design for energy storage system

-

Liquid cooling system for medium-sized energy storage power stations

Liquid cooling system for medium-sized energy storage power stations

-

Energy Storage Container Liquid Cooling System

Energy Storage Container Liquid Cooling System

-

Liquid Cooling Energy Storage Project System Solution

Liquid Cooling Energy Storage Project System Solution

-

Turkmenistan liquid cooling energy storage container price

Turkmenistan liquid cooling energy storage container price

Industrial & Commercial Energy Storage Market Growth

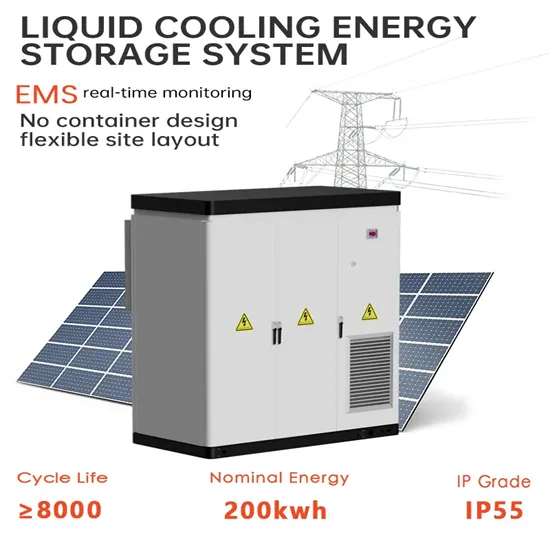

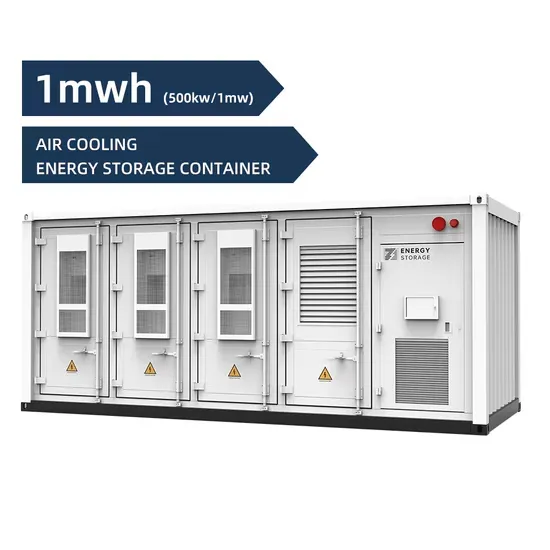

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.