Detailed Explanation of the Operating Steps of Glass Separation

Advanced glass separation equipment plays a pivotal role in optimizing this process, ensuring high recovery rates while minimizing environmental impact. Below is a step

Get a quote

Automated Bifacial PV Panel Recycling Line Solution

Double Glass Solar Module Recycling Machine Line The line is capable of handling panels of various sizes and separates high-value materials, including glass, copper, silicon powder, and

Get a quote

Multiphasic condensates formed with mono-component of

Biomolecular condensates, formed by liquid-liquid phase separation of biomacromolecules, play crucial roles in regulating physiological events in biological systems.

Get a quote

Separation Techniques | Edexcel IGCSE Science

Revision notes on Separation Techniques for the Edexcel IGCSE Science (Double Award) syllabus, written by the Science experts at Save My

Get a quote

Chromatographic Separation Strategies for Multi

Explore key chromatographic separation strategies for multi-component analysis in gradient elution, column selection, temperature control,

Get a quote

What are the advantages of dual-glass Dualsun modules?

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the

Get a quote

Separating insulated glass: Utilising imperfect panes

With the IG2Pieces assembly line technology, HEGLA has developed a solution that can automatically separate insulated glass. At the

Get a quote

Chromatographic Separation Strategies for Multi-Component

Explore key chromatographic separation strategies for multi-component analysis in gradient elution, column selection, temperature control, flow rate, and mobile phase optimization.

Get a quote

Solar Panel (Double Glass) Recycling Machine

3 days ago· Discover how our Solar Panel (Double Glass) Recycling Line efficiently handles advanced PV modules. Using specialized crushing and separation technology, the system recovers valuable materials

Get a quote

Technical Guide: Area Separation Walls (DensGlass®

DensGlass® Shaftliner is a unique area separation wall panel and a key component of an Area Separation Wall assembly for use in multi-family townhouses. DensGlass Shaftliner consists of

Get a quote

Separating insulated glass: Utilising imperfect panes and end-of

With the IG2Pieces assembly line technology, HEGLA has developed a solution that can automatically separate insulated glass. At the same time, the company offers a

Get a quote

Physics Tutorial: Dispersion of Light by Prisms

The refraction of light at the entry location into the rectangular glass prism would cause a little separation of the white light. However, upon exiting the glass prism, the refraction takes place

Get a quote

Disassembling insulating glass panes for recycling

Disassembling insulating glass panes for recycling IG2Pieces has been developed by HEGLA as a machine concept for separating insulating glass for high-quality recycling, reuse or the repair

Get a quote

Double Glazed Sealed Units (DGU)

We are the specialists in manufacturing double glazed units, otherwise known as DGU''s. All of our units are compliant with BSEN 1279 Parts 1 to 6 and carry

Get a quote

Double-glass structure assembly separation and recovery method

TL;DR: In this paper, a double-sided glass assembly with two sets of hooks between the long edge gaps of the assembly is presented, where a complete battery piece and glass can be

Get a quote

Solar Panel (Double Glass) Recycling Machine

Discover how our Solar Panel (Double Glass) Recycling Line efficiently handles advanced PV modules. Using specialized crushing and separation technology, the system recovers valuable

Get a quote

Components Separation Technique Combined with a Double

The components-separation technique in combination with a double-mesh has shown a low recurrence rate in the short-term follow-up. However, there is a considerable occurrence of

Get a quote

Detailed Explanation of the Operating Steps of Glass

Advanced glass separation equipment plays a pivotal role in optimizing this process, ensuring high recovery rates while minimizing

Get a quote

Glass phase extraction for one-step separation and recovery of

Here, glass phase extraction is proposed as a novel approach for simultaneously separating metals and obtaining recovered products from spent hydrofining catalysts in one step.

Get a quote

Disassembling insulating glass panes for recycling

Disassembling insulating glass panes for recycling IG2Pieces has been developed by HEGLA as a machine concept for separating insulating glass for

Get a quote

Microsoft Word

A process in which components of a mixture are exposed to two very different physical environments – a stationary phase and a mobile phase. Usually, two components in a mixture

Get a quote

Amazon : Tryteava Glass Infuser, Teava 3-in-1 Smart Tea

About this item 【3-in-1 Smart Design】Experience effortless tea brewing with the Teava 3-in-1 smart tea infuser. It ingeniously combines a teapot, infuser, and drinking vessel in

Get a quote

6 FAQs about [Double glass component separation]

Can glass phase extraction be used for metal separation?

However, glass extraction strategies have yet to be applied and generalized for metal separation and the recovery of wastes. Herein, glass phase extraction is proposed as a one-step approach to simultaneously separate metals and obtain recovered products from a spent catalyst.

What is glass phase – crystal phase separation?

The constructed glass phase provided a coordination environment for the selective extraction of Al 3+ and Ni 2+, while Mo 6+ with high F was enriched in the molybdate phase and migrated, accompanied by one-step “glass phase – crystal phase separation” and direct recovery.

What are the factors affecting the separation of metals by glass phase extraction?

The melting temperature is one of the key influencing factors for the separation of metals by glass phase extraction. The thermal decomposition of Na 2 SO 4 and the spontaneous reaction with MoO 3 require temperatures higher than 1184 °C, which corresponds to the exothermic peak of the TG-DTA curve shown in Fig. 6.

What are the different types of glass chromatography columns?

Glass chromatography columns are available in various types, each designed to address specific separation needs: Standard Columns: These versatile columns are suitable for a wide range of chromatography techniques, including gravity and low-pressure chromatography.

What is glass phase extraction?

Herein, glass phase extraction is proposed as a one-step approach to simultaneously separate metals and obtain recovered products from a spent catalyst. Specifically, a spent MoNi/γ-Al 2 O 3 hydrofining catalyst was used as a representative sample catalyst material.

What is glass phase extraction (GPE)?

Glass phase extraction (GPE), a new method was proposed for metal separation. >99.16 % Al 3+ and Ni 2+ were extracted and separated with 99.82 % Mo 6+ by GPE. Na 2 MoO 4 was immiscible with and precipitated over glass melt, recovered directly. Full-component resource recovery of spent catalysts was achieved by GPE method.

Guess what you want to know

-

Double glass component embedding

Double glass component embedding

-

Double glass component frame

Double glass component frame

-

Yaounde photovoltaic enterprise double glass solar panels

Yaounde photovoltaic enterprise double glass solar panels

-

Double glass monocrystalline perc photovoltaic panel

Double glass monocrystalline perc photovoltaic panel

-

Double glass module rear power

Double glass module rear power

-

Double glass module transmittance adjustable manufacturer

Double glass module transmittance adjustable manufacturer

-

Double glass roof

Double glass roof

-

Photovoltaic module double glass frame

Photovoltaic module double glass frame

-

Mauritania double glass photovoltaic curtain wall customization

Mauritania double glass photovoltaic curtain wall customization

-

Solar PVB double glass modules

Solar PVB double glass modules

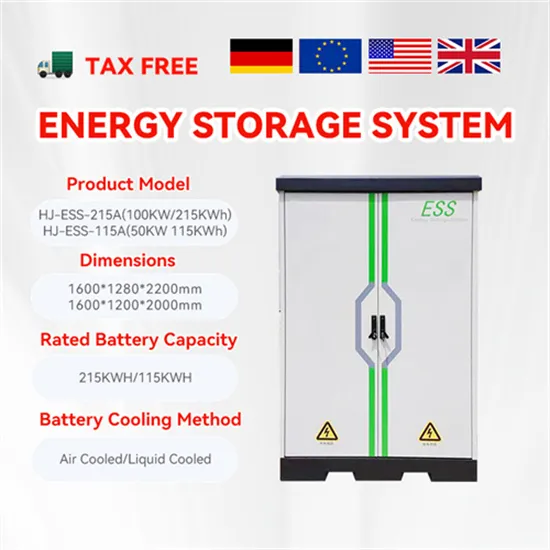

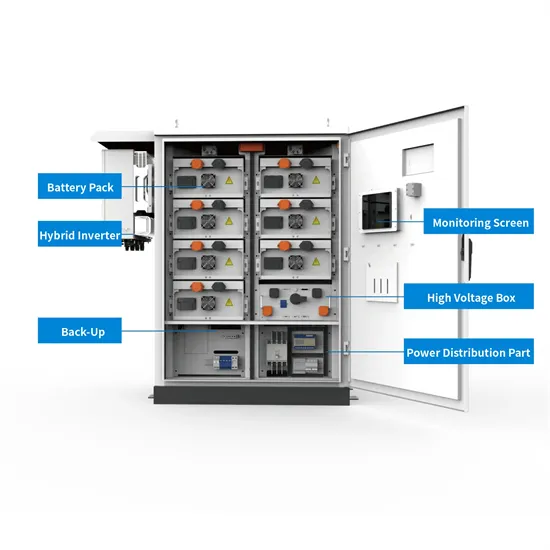

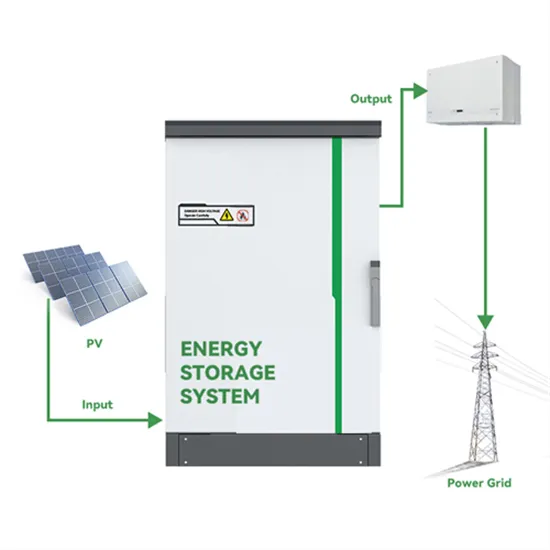

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

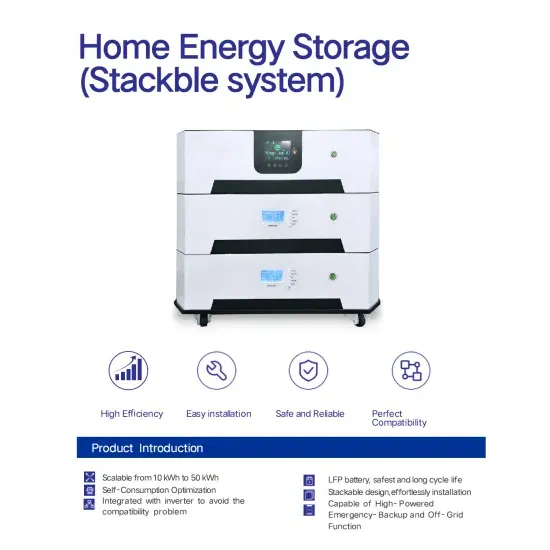

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.