How Are Lithium Ion Batteries Manufactured

Discover the step-by-step process of lithium ion battery manufacturing, from raw material extraction to battery pack assembly, ensuring safety and efficiency.

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

Battery Module: Manufacturing, Assembly and Test

In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

Lithium Cell Manufacturing Line

Lithium Cell Manufacturing Line: Key to Efficient and Scalable Battery Production A lithium cell manufacturing line is a specialized production facility designed to manufacture

Get a quote

Introduction to the Working Principle and Production Method of Lithium

Lithium battery packs are a crucial component of modern technology, powering everything from smartphones and laptops to electric vehicles and renewable energy storage systems.

Get a quote

Battery Manufacturing-How We Build Your Custom Battery Packs

Looking for 18650 or 21700 lithium ion battery packs tailored to your needs? Whether it''s compact and lightweight packs for portable devices or high-power solutions for

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

The environmental footprint of electric vehicle battery packs

Purpose Battery electric vehicles (BEVs) have been widely publicized. Their driving performances depend mainly on lithium-ion batteries (LIBs). Research on this topic has

Get a quote

Amazon : Lithium Power Pack

TalentCell Rechargeable 12V 6000mAh/5V 12000mAh DC Output Lithium ion Battery Pack for LED Strip/CCTV Camera/Telescope/Modem and More, Portable Li-ion Power Bank with 12.6V

Get a quote

Understanding the production process of lithium

Understand the production process of lithium battery pack cells in one article. The packaging of lithium-ion batteries is divided into two categories: metal shell

Get a quote

Battery Production Flyer: Lithion Ion Cell Production

The chair "Production Engineering of E-Mobility Components" (PEM) of RWTH Aachen University has been active in the field of lithium-ion battery production technology for many years. These

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

Get a quote

PRODUCTION PROCESS OF BATTERY MODULES AND

The publication "Production process of a lithium-ion battery cell" provides a comprehensive process overview of the production of different battery cell formats from electrode

Get a quote

How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

Get a quote

Lithium-Ion Battery Manufacturing: Industrial View on

Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get a quote

What Is the Process of Lithium-Ion Battery Pack

As a vital element in the lithium ion battery manufacture process, the pack plays a pivotal role in the production, design, and application of

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get a quote

What Is the Process of Lithium-Ion Battery Pack Assembly Production

As a vital element in the lithium ion battery manufacture process, the pack plays a pivotal role in the production, design, and application of power battery systems.

Get a quote

Understanding Lithium Ion Battery Packs: Types, Uses, and

Lithium ion battery packs are integral to modern technology and sustainable energy solutions. By understanding the different types, their uses, and adhering to safety

Get a quote

What Is the Process of Lithium-Ion Battery Pack

The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Get a quote

Battery Manufacturing-How We Build Your Custom

Looking for 18650 or 21700 lithium ion battery packs tailored to your needs? Whether it''s compact and lightweight packs for portable devices

Get a quote

Lithium-ion battery pack applications and production process

Objectively speaking, the production process of lithium-ion battery packs is divided into three parts, one is the production of the cells, another is the production of the battery cells and the

Get a quote

Guess what you want to know

-

Production of lithium battery packs for communication base stations

Production of lithium battery packs for communication base stations

-

Lithium battery outdoor power supply production

Lithium battery outdoor power supply production

-

Top production of lithium battery packs

Top production of lithium battery packs

-

Japanese lithium battery production outdoor power supply

Japanese lithium battery production outdoor power supply

-

What protection do lithium battery packs need

What protection do lithium battery packs need

-

Where can I buy 80AH lithium battery packs in Bosnia and Herzegovina

Where can I buy 80AH lithium battery packs in Bosnia and Herzegovina

-

Lithium Battery Outdoor Power Supply Ranking

Lithium Battery Outdoor Power Supply Ranking

-

Lithium battery life for outdoor power supply in Poland

Lithium battery life for outdoor power supply in Poland

-

Battery Packs and Lithium Batteries

Battery Packs and Lithium Batteries

-

Malaysia produces solar lithium battery packs

Malaysia produces solar lithium battery packs

Industrial & Commercial Energy Storage Market Growth

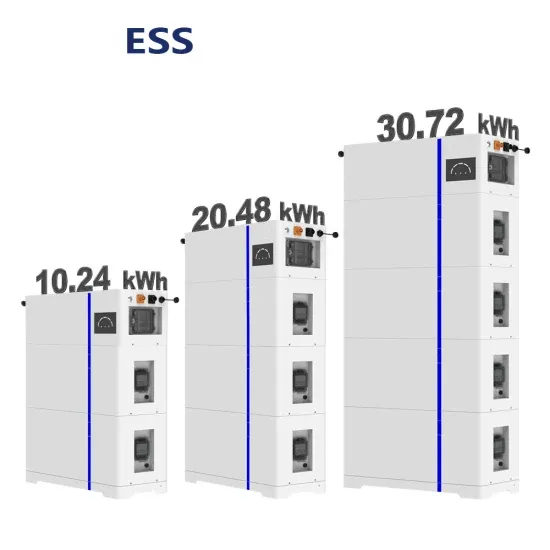

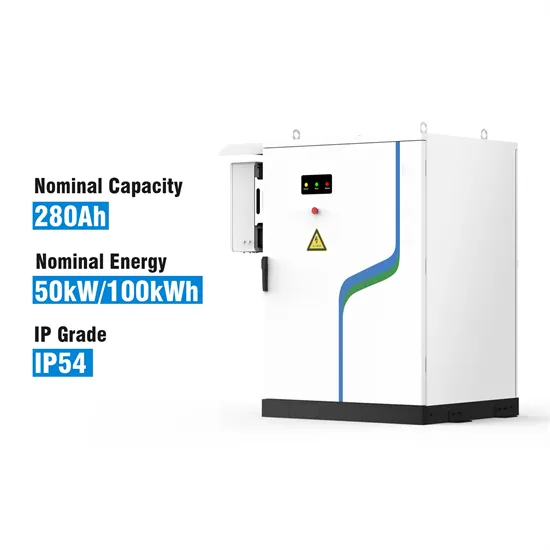

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.