eriyabv

The global flywheel energy storage systems market size was estimated at USD 461.11 billion in 2024 and is expected to grow at a CAGR of 5.2% from 2025 to 2030. High initial costs are a

Get a quote

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Conducting detailed cost-benefit analyses for specific FES applications, such as frequency regulation or renewable energy integration. Investigating the impact of FES on grid

Get a quote

Flywheel Energy Storage Systems (FESS)

Flywheel energy storage systems (FESS) use electric energy input which is stored in the form of kinetic energy. Kinetic energy can be described as

Get a quote

Approximate cost of flywheel energy storage

Is flywheel energy storage a viable energy source? This flywheel energy storage design is a viable electricity sourcein homes. It functions to meet peak power demands within 25

Get a quote

DOE ESHB Chapter 7 Flywheels

Flywheel systems in service today demonstrate millisecond response times, energy storage up to 700 kWh per rotor, power output of up to 500 MW per rotor, and decades of service life.

Get a quote

flywheel energy storage cost per kWh

Flywheel energy storage addresses the critical gap between energy supply and demand fluctuations that batteries struggle to handle. While lithium-ion batteries dominate 78% of

Get a quote

Flywheel energy storage cost kwh

How does a flywheel energy storage system work? The flywheel energy storage system mainly stores energy through the inertia of the high-speed rotation of the rotor. In order to fully utilize

Get a quote

Hybrid energy storage flywheel cost

s d is the coefficient of daily cost for flywheel energy storage over the total lifecycle cost, P FS is the investment cost of the flywheel energy storage unit per kWh, S FS is

Get a quote

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Formula: CapEx = (Number of Flywheels) * (Flywheel Cost per Unit) Operating Expenditure (OpEx): The recurring costs associated with maintaining and operating the FES,

Get a quote

Energy Storage Technology and Cost Characterization Report

Capital costs for electrochemical storage devices are typically expressed in dollars per kilowatt hour ($/kWh), while those for flywheels, PSH, CAES, and combustion turbines (CTs) are

Get a quote

RotorVault Energy Storage Cost Analysis and Flywheel Price

Explore RotorVault''s cost-competitiveness and scalability. A comparative cost analysis with Battery and Flywheel Energy Storage Systems.

Get a quote

Flywheel Energy Storage Costs: Breaking Down the Economics

This is where flywheel energy storage enters the conversation with its 100,000+ cycle lifespan and instant response capabilities. But here''s the catch - why hasn''t this technology dominated the

Get a quote

Flywheels as Batteries

A reasonable estimate for the cost of lithium ion batteries in 2018 is about $300 kWh -1, so we see that purely from a cost perspective the flywheel solution is

Get a quote

The development of a techno-economic model for the

Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications. There is a

Get a quote

Flywheel energy storage system price per KW

The total cost can be broken down into the following categories: (1) ESS cost, which is actually the overnight capital cost of the storage unit and can be divided into two parts, namely cost per

Get a quote

flywheel energy storage cost per kwh

The average flywheel storage cost can vary greatly, ranging from $500 to $1500 per kilowatt-hour (kWh). Whether flywheel storage is more expensive than other energy storage options

Get a quote

Energy Storage Cost and Performance Database

The U.S. Department of Energy''s (DOE) Energy Storage Grand Challenge is a comprehensive program that seeks to accelerate the development,

Get a quote

Cost-Benefit Analysis of Flywheel Energy Storage in context of

Conducting detailed cost-benefit analyses for specific FES applications, such as frequency regulation or renewable energy integration. Investigating the impact of FES on grid

Get a quote

A review of flywheel energy storage systems: state of the art and

For instance, Beacon Power''s flywheel costs almost ten times higher than a Li-ion battery system with similar energy capacity even though it can provide competitive cost per

Get a quote

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

NASA''s 2023 lunar base prototype used flywheels storing energy at $780/kWh - 22% cheaper than their moon-grade lithium batteries. Closer to Earth, Tesla''s Texas factory

Get a quote

Flywheel Systems for Utility Scale Energy Storage

The Amber Kinetics M32 flywheel is a 32 kilowatt-hour (kWh) kinetic energy storage device designed with a power rating of 8kW and a 4-hour discharge duration (Figure ES-1).

Get a quote

How much does a flywheel energy storage system cost?

How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors,

Get a quote

Flywheel Energy Storage Cost per kWh: Efficiency Meets

As global industries seek cost-effective energy storage, flywheel systems emerge as game-changers with flywheel energy storage cost per kWh dropping 28% since 2020.

Get a quote

What is the average cost of a home battery? – Torus

Battery Capacity: The storage capacity of a solar battery, measured in kilowatt-hours (kWh), plays a huge role in determining its cost. Batteries with higher capacity can store more energy, so

Get a quote

How much does a flywheel energy storage system cost?

How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors, including size, design, and installation

Get a quote

6 FAQs about [The cost of flywheel energy storage per kilowatt-hour]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

Are flywheel energy storage systems a good alternative to electro-chemical batteries?

Electro-chemical ESSs can be used in short-duration services , , but they suffer from a short lifetime and the need to dispose of toxic materials , . Flywheel energy storage systems (FESSs) are a promising alternative to electro-chemical batteries for short-duration support to the grid .

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

How much does a flywheel power converter cost?

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

What is the largest flywheel energy storage?

The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration . Utility-scale flywheel storage is typically used for frequency regulation to maintain grid frequency by matching electricity supply and demand for a short period, usually 15 min , .

Guess what you want to know

-

Flywheel energy storage energy cost

Flywheel energy storage energy cost

-

Comprehensive cost of energy storage per kilowatt-hour

Comprehensive cost of energy storage per kilowatt-hour

-

Energy storage product cost per kilowatt-hour

Energy storage product cost per kilowatt-hour

-

Lead-carbon battery energy storage cost per kilowatt-hour

Lead-carbon battery energy storage cost per kilowatt-hour

-

Energy storage cabinet electricity cost per kilowatt-hour

Energy storage cabinet electricity cost per kilowatt-hour

-

How to calculate the construction cost of energy storage cabinet

How to calculate the construction cost of energy storage cabinet

-

How much does lithium battery energy storage cost

How much does lithium battery energy storage cost

-

Grid-side energy storage power station cost BESS

Grid-side energy storage power station cost BESS

-

How much does 100 kWh of photovoltaic energy storage cost

How much does 100 kWh of photovoltaic energy storage cost

-

Photovoltaic energy storage system 5kw cost

Photovoltaic energy storage system 5kw cost

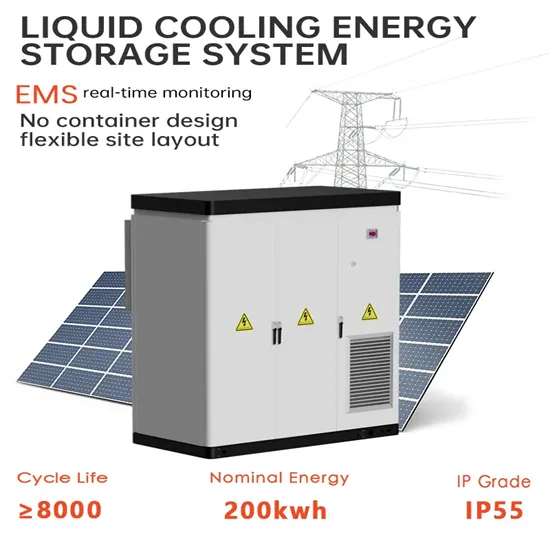

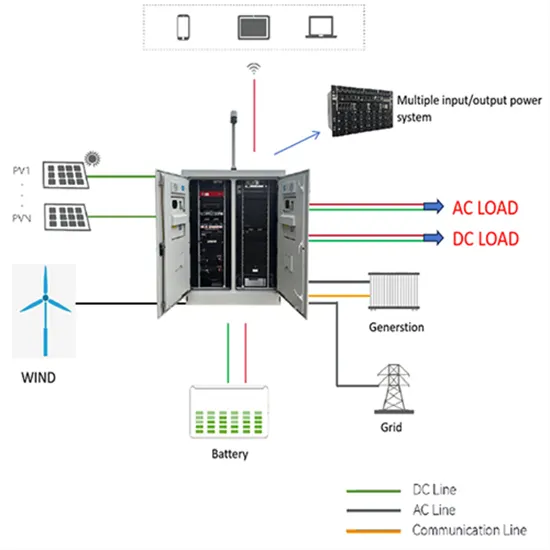

Industrial & Commercial Energy Storage Market Growth

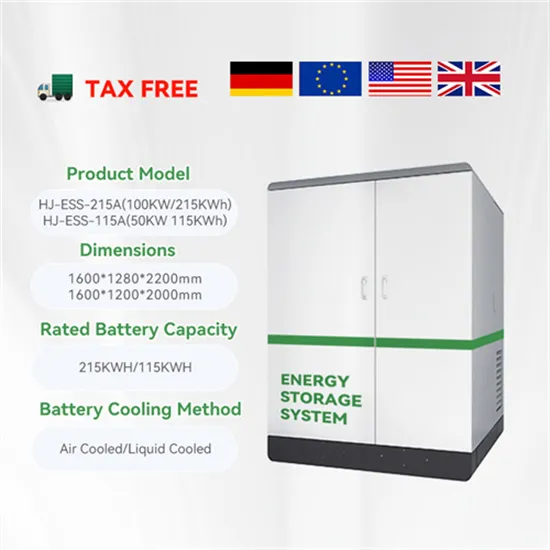

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

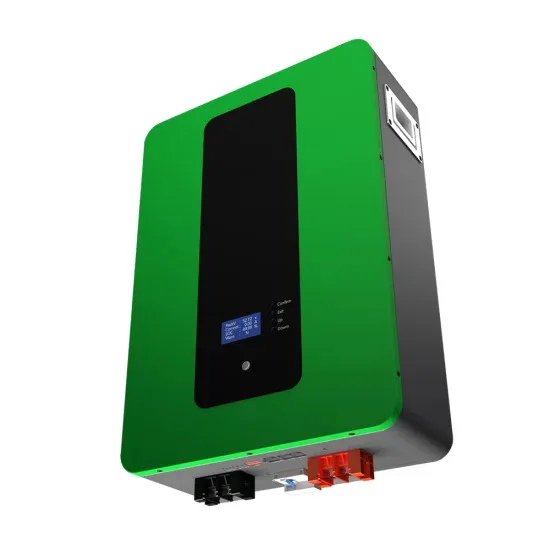

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.