Servo Drive Installation Best Practices

Introduction Use this publication as a quick reference guide of installation best practices for Rockwell Automation® single-axis and multi-axis servo drive systems. These practices also

Get a quote

Servo Driver vs. Inverter: What Are the Key Differences?

Inverter: Inverters typically use simpler control algorithms, such as V/F control (Voltage/Frequency control) or vector control. V/F control

Get a quote

How Inverters Control Servo AC Motors

By controlling the on-off states of the switching devices, the inverter can output AC power with different frequencies and voltages, thereby controlling the servo AC motor.

Get a quote

Servomotors / Servo Drivers

What Is a Servomotor and What Is a Servo Drive? A servomotor is a structural unit of a servo system and is used with a servo drive. The servomotor includes

Get a quote

Servo Driver VS. Inverter: Understanding the Difference

In this blog post, we will explore the differences between servo drivers and inverters and discuss their respective applications. Servo drivers, also known

Get a quote

What is Servo Drive

After the rectified three-phase power or mains power, the three-phase permanent magnet synchronous AC servo motor is driven by a three-phase sinusoidal PWM voltage

Get a quote

Analysis of the difference between servo drive and inverter

Frequency conversion is a necessary internal link of servo control, and there is also frequency conversion in the servo drive (for stepless speed regulation). However, the servo controls the

Get a quote

Precision ADCs in Servo Drives

Within the servo drive, there is an internal 3-phase inverter that takes in DC voltage from a power supply and converts to AC voltage through a pulse width modulator (PWM).

Get a quote

LAP 1 Introduction to AC Drives Flashcards | Quizlet

Study with Quizlet and memorize flashcards containing terms like VFDs are used to control the ______________ and torque of AC induction motors., The speed of an AC

Get a quote

Servo Stabilizer: What It Is, How It Works, and Why You Need One

Protect your devices with a servo stabilizer. Learn how it works, its benefits, and tips to choose the best one for voltage regulation!

Get a quote

Servo Inverter – What You Need to Know-CM Industry Supply Blogs

A servo inverter is an electronic device that takes an AC voltage input and produces a three-phase AC output with a variable frequency. The frequency can be set to

Get a quote

Servo Drives – Technology Transfer Services

DC to AC Inverter – The inverter takes the DC power from the DC bus and inverts it back to AC using pulse width modulation, which controls the voltage and frequency to the servo motor. AC

Get a quote

Powering AC Servo Drive using VFD

An A-B PowerFlex 755 drive can be used to power your servo motors, and you can double the size of the drive to be able to feed it with single phase power. But you will need

Get a quote

Servo Driver vs. Inverter: What Are the Key Differences?

Inverter: Inverters typically use simpler control algorithms, such as V/F control (Voltage/Frequency control) or vector control. V/F control maintains a constant voltage-to

Get a quote

How to Use Inverter Drives with RDC Earth Leakage Protected Supplies

The leakage through the Inverter EMC filters varies from around 20mA upwards, depending on the type of filter (Industrial or Domestic) and the size of the inverter. There are different types

Get a quote

Mastering the Servo Drive Installation Process: A Comprehensive

Learn how to master the installation of Darwin Motion servo drives with our comprehensive guide. Follow step-by-step instructions for optimal performance and reliability

Get a quote

Servo Driver VS. Inverter: Understanding the Difference

In this blog post, we will explore the differences between servo drivers and inverters and discuss their respective applications. Servo drivers, also known as CNC drives, are specialized

Get a quote

CSM_Servo_TG_E_1_1

servo drive uses internal regenerative processing circuits to absorb the regenerative energy generated by a motor when the motor decelerates to prevent the DC voltage from increasing.

Get a quote

Advanced Inverter Drive Parameter Settings

Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility. While basic

Get a quote

Servo Drive: Components & Benefits Explained

In today''s high-precision automation landscape, servo drives—also known as servo amplifiers—play a mission-critical role in ensuring motion

Get a quote

Why do servo drives use PWM and how does it work?

A PWM (pulse-width modulation) amplifier switches the transistors in the inverter section of the drive on-and-off to modulate the voltage to the motor.

Get a quote

Guess what you want to know

-

Use inverter when voltage is high

Use inverter when voltage is high

-

How much voltage can a 20kw inverter drive

How much voltage can a 20kw inverter drive

-

Can I use an inverter if the battery voltage is low

Can I use an inverter if the battery voltage is low

-

Inverter fixed DC voltage control

Inverter fixed DC voltage control

-

What size battery should I use with a power frequency inverter

What size battery should I use with a power frequency inverter

-

How much voltage should I choose for the inverter

How much voltage should I choose for the inverter

-

Is a high-power inverter easy to use

Is a high-power inverter easy to use

-

Amorphous machine inverter high voltage

Amorphous machine inverter high voltage

-

Ghana high voltage inverter manufacturer

Ghana high voltage inverter manufacturer

-

High frequency inverter voltage can reach

High frequency inverter voltage can reach

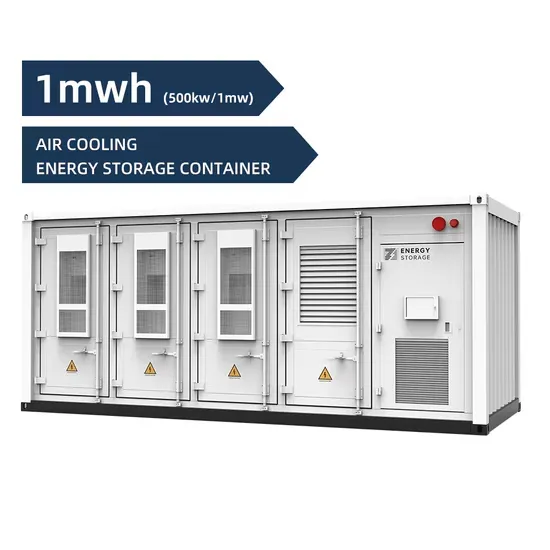

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.