卸货指南_20240708

The following is the correct way of packing, unpacking, unloading, storage and transportation of AESOLAR photovoltaic modules. The package consists of double corrugated cow card carton,

Get a quote

CN115832088A

The invention discloses a flexible anti-pulling photovoltaic module and a preparation method thereof, belonging to the technical field of photovoltaic modules, and being characterized by

Get a quote

Mobile Solar Container Solution| Mobile Solar

The brand new self-sustainable Containerized Solar PV Solution by Statcon Energiaa provides a ready-made alternative for the common problem of power

Get a quote

PV Modules Logistics & Unloading & Unpacking

Ensure the modules and packaging are placed on the flat ground without sharp and protruding debris to avoid tipping. Under any circumstances, do not pile more than two layers of long-side

Get a quote

Mastering the Art of Vertical Packing for Photovoltaic Panels: A

To Master the Vertical Packing Technique of Photovoltaic Panels, learn first why it''s been such a buzz for mobile deployment, what techniques make it valuable, and how to

Get a quote

Unloading & Unpacking of Solar Modules

They provide important information and guidelines for the safe unloading and unpacking of the solar modules. In order to ensure a proper and correct procedure for unloading and unpacking,

Get a quote

Best practices for handling, unpacking and storing large-format

Preinstallation training should be encouraged as well as the sharing of best practices to help ensure the safe unpacking, inspection, handling and installation of modules.

Get a quote

Solar Options

Stealth Power provides fleet electrification and off grid solar solutions for customers of all kinds. They have explored and implemented solar options for a wide variety of applications and we

Get a quote

Mobile Container PV Module Cabinet

Mobile PV solar containers is a wise choice of low investment and high return. The lightweight PV module is integrated in a 20/40 foot standard container. After reaching the designated location,

Get a quote

Austrian startup launches portable containerized PV

Solarcont has developed a portable, containerized PV system featuring 240 solar modules on a folding system for easy removal and storage.

Get a quote

How Many Solar Panels Will Fit in a Shipping Container?

How might technological innovations, such as automated palletizing or AI-driven logistics planning, further improve solar panel

Get a quote

How to load and unload a whole box of photovoltaic panels

In this article, we will explore the significance of effective solar panel packaging, delve into the selection of appropriate materials and design, discuss secure loading and unloading

Get a quote

Unloading & Unpacking of Solar Modules

Solar module packaging On the front side of each box you will find a list of the individual module data (flash data) of the solar modules on the pallet. For security reasons, you will also receive

Get a quote

Safe Unloading Solar modules from the Container.

Discover the safest methods for unloading solar modules at your project site. This video covers proper lifting techniques, necessary PPE, and efficient teamwork to ensure the

Get a quote

How to Protect Solar Panels from Damage Transporting

If you opt for taking panels as they are, prepare some sort of solar panel packaging to minimize the risk of cracking the module. Foam pads, bubble wrap, and even

Get a quote

A product that has attracted worldwide attention – Folding photovoltaic

Background Note: Standard shipping containers for 20-foot shipping size are approximately 6.06 m in length and 2.59 m in width, offering a standard form for retrofitting

Get a quote

How to Protect Solar Panels from Damage Transporting

If you opt for taking panels as they are, prepare some sort of solar panel packaging to minimize the risk of cracking the module. Foam pads,

Get a quote

Packaging Datasheet1

To ensure the safety of loading, unloading, unpacking. and storage of PV modules, please read this manual carefully. When you need to unpack and install the modules, you can search and

Get a quote

PV Module Unpacking, Handling and Storing Guide

This guide serves as a reference for inspecting, transporting, unpacking, handling and storing LONGi PV solar modules to ensure safe practices for you and the modules.

Get a quote

solarfold | Mobile Solar Container

Der mobile Antrieb – bestehend aus einer flexiblen Mitnehmereinheit welche auf Traversen gelagert ist – kann auch für weitere solarfold PV-Kraftwerke

Get a quote

Solar Panels on Shipping Containers

Key Takeaways Solar panels on shipping containers offer a versatile and cost-effective solution for harnessing renewable energy, providing sustainable

Get a quote

TLS news & blogs

Solar energy containers epitomize the pinnacle of sustainable energy solutions, offering a plethora of benefits across diverse applications. From their renewable energy

Get a quote

Containerized Photovoltaic Modules – Wholesale Solar Systems

Wholesale of photovoltaic modules for full containers In this section we offer photovoltaic modules that can be purchased only for full containers. The aim is to be able to offer operators who

Get a quote

Best practices for handling, unpacking and storing

Preinstallation training should be encouraged as well as the sharing of best practices to help ensure the safe unpacking, inspection, handling and

Get a quote

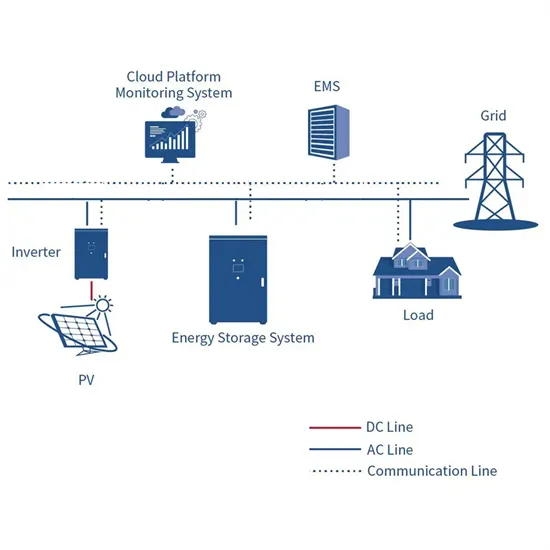

Solar PV Energy storage box installation and wiring

In off-grid business use, a Solar PV Energy Storage box represents an autonomous power solution that has photovoltaic (PV) arrays,

Get a quote

6 FAQs about [Pulling photovoltaic module containers]

How do I know if my PV modules have been shipped?

Before you unpack your modules, check the shipping label to ensure you received the right modules. Once you unpack your modules, check the module frame serial number and model label against the shipping label. The serial number is the unique identifier of each PV module.

How are the modules transported?

The modules shall be transported on a flat ground; When taking the modules out of the box, it is recommended to use protective tooling to separate the modules to prevent friction from producing flecks.

Why is my PV module not working?

Improper handling or bad placement can cause microcracks in PV modules which immediately lower their power. Crystalline modules are especially fragile, while thin-film panels are usually more sturdy. In fact, some manufacturers claim that you can even step on certain thin-film panels, though we wouldn't recommend doing it anyways.

How to store the modules?

The modules shall be stored in a complete outer package. The storage area shall be protected pallets and boxes from damp, direct sunlight and waterproof (rain) measures; The modules should be placed neatly with a safe distance between the boxes. The spacing between boxes should be greater than 30cm(Figure 10);

Where should a module package be located in a forklift?

One side of the module package should be close to the retainer (Figure1); When using a forklift to move palletized packing boxes to the operation area, the forklift shall be slowly and steadily lifted and put down gently during loading and unloading, and the modules shall avoid turbulence and violent vibration during transportation.

How to unpack a module?

Remove the wrapping film around the box and separate the upper and lower boxes. The long side of the module to unpacked needs to be close to a solid support for about 15-20cm distance, the support could be a wall, rack or another unpacked module box of the same type, and then use scissors to cut all the packing strap of the outer box.

Guess what you want to know

-

Photovoltaic inverter DCAC module

Photovoltaic inverter DCAC module

-

Photovoltaic module bifaciality standard requirements

Photovoltaic module bifaciality standard requirements

-

Are photovoltaic containers of Myanmar effective

Are photovoltaic containers of Myanmar effective

-

Do containers have photovoltaic power generation

Do containers have photovoltaic power generation

-

Senegal solar photovoltaic module manufacturer

Senegal solar photovoltaic module manufacturer

-

How much does a monocrystalline silicon photovoltaic module cost

How much does a monocrystalline silicon photovoltaic module cost

-

Good photovoltaic module prices in China

Good photovoltaic module prices in China

-

Rooftop distributed photovoltaic module price

Rooftop distributed photovoltaic module price

-

Thin-film photovoltaic module production

Thin-film photovoltaic module production

-

Photovoltaic double-glass module back connector

Photovoltaic double-glass module back connector

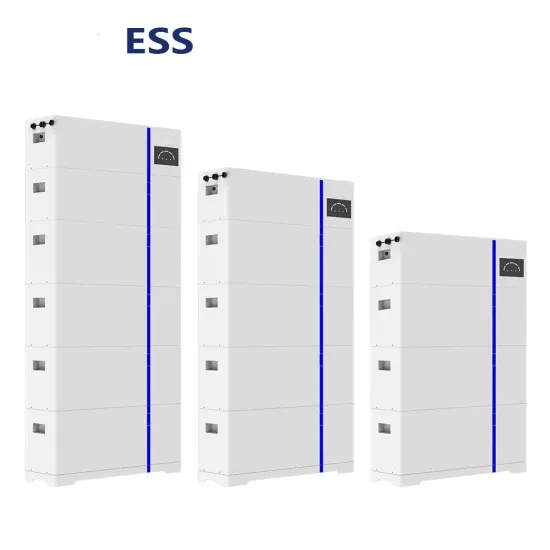

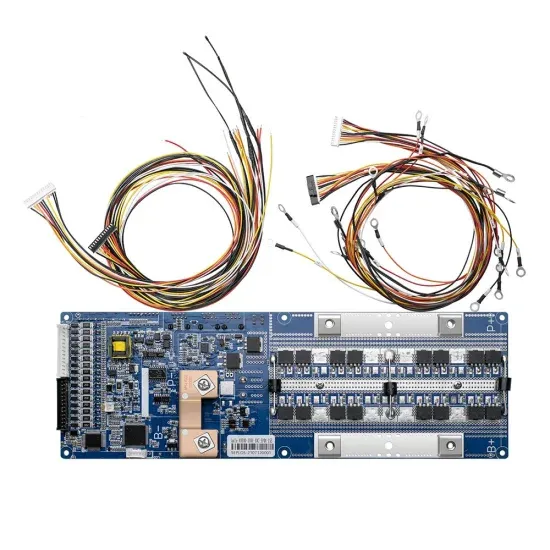

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.