Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Get a quote

Containerized energy storage system | VREMT

Containerized energy storage is an Advanced, safe, and flexible energy solution featuring modular design, smart fire protection, efficient thermal management, and intelligent control for optimal

Get a quote

Simulation analysis and optimization of containerized energy

This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Get a quote

Designing a BESS Container: A Comprehensive Guide to Battery Energy

The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Get a quote

Modeling and analysis of liquid-cooling thermal management of

A self-developed thermal safety management system (TSMS), which can evaluate the cooling demand and safety state of batteries in real-time, is equipped with the energy

Get a quote

Design of Thermal Management for Container Type Energy Storage

This article focuses on the design of the thermal management system''s cooling duct structure, air conditioning, battery module cooling fan, and temperature control strategy for the megawatt

Get a quote

Design of Thermal Management for Container Type Energy

This article focuses on the design of the thermal management system''s cooling duct structure, air conditioning, battery module cooling fan, and temperature control strategy for the megawatt

Get a quote

THERMAL MANAGEMENT FOR ENERGY STORAGE:

The choice of energy storage temperature control technology is the result of a comprehensive consideration of factors such as safety, economy, battery pack design, and the

Get a quote

Battery energy storage system (BESS) container,

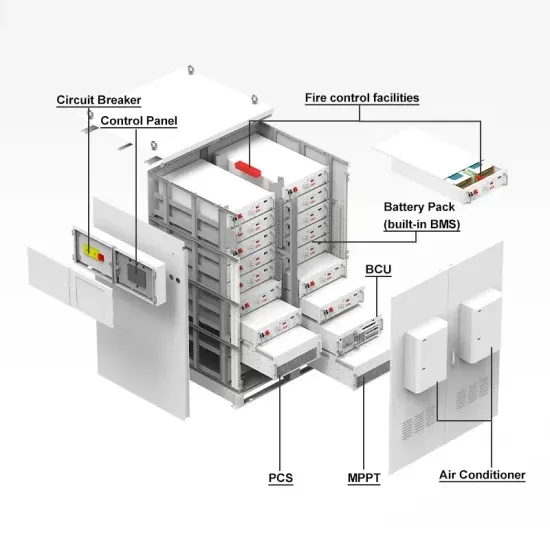

BESS (Battery Energy Storage System) is an advanced energy storage solution that utilizes rechargeable batteries to store and release electricity as needed.

Get a quote

Thermal management analysis of energy storage containers

In this paper, the heat dissipation behavior of the thermal management system of the container energy storage system is investigated based on the fluid dynamics simulation

Get a quote

Container Energy Storage System

Product Introduction: All-in-one system combining LFP batteries, PCS, fire protection, and intelligent temperature control with a standard container design for easy transport. High

Get a quote

Research and application of containerized energy storage thermal management

The article covers various aspects including system equipment, control strategy, design calculation, and insulation layer design. The research emphasizes the study of thermal

Get a quote

Simulation analysis and optimization of containerized energy storage

This study analyses the thermal performance and optimizes the thermal management system of a 1540 kWh containerized energy storage battery system using CFD

Get a quote

Key Considerations in Energy Storage Container Design

Designing an energy storage container is a complex process that requires careful attention to numerous technical, environmental, and logistical factors. Safety, efficiency, and

Get a quote

Detailed Understanding of the Containerized Battery System

A pre-assembled, modular energy storage device contained inside a normal shipping container is known as a containerized battery system. These systems, which are self

Get a quote

Exploring BESS Containers: A Deep Dive into Cutting-Edge

1 day ago· Battery Energy Storage System (BESS) containers aren''t just metal boxes—they''re the grid''s "reliability sidekicks," and Innovative Technologies in BESS Containers are what turn

Get a quote

Thermal Design of Energy Storage Containers: Balancing

The thermal design of energy storage containers is the unsung hero keeping lithium-ion batteries from throwing tantrums (or worse, catching fire). Let''s explore how engineers are solving this

Get a quote

A thermal‐optimal design of lithium‐ion battery for the container

The above results provide an approach to exploring the optimal design method of lithium‐ion batteries for the container storage system with better thermal performance.

Get a quote

Thermal Design of Energy Storage Containers: Balancing

Turns out, energy storage containers share that pain. The thermal design of energy storage containers is the unsung hero keeping lithium-ion batteries from throwing tantrums (or worse,

Get a quote

A thermal‐optimal design of lithium‐ion battery for the

The above results provide an approach to exploring the optimal design method of lithium‐ion batteries for the container storage system with

Get a quote

Research and application of containerized energy

The article covers various aspects including system equipment, control strategy, design calculation, and insulation layer design. The research

Get a quote

Containerized energy storage system | VREMT

Containerized energy storage is an Advanced, safe, and flexible energy solution featuring modular design, smart fire protection, efficient thermal management,

Get a quote

Research and optimization of thermal design of a container

The thermal performance of the battery module of a container energy storage system is analyzed based on the computational fluid dynamics simulation technology. The air distribution

Get a quote

Thermal management design of container energy storage

This article takes the container type battery energy storage system used in a large-scale energy storage power station demonstration project in China as the research object, and discusses in

Get a quote

Liquid Cooling System Design, Calculation, and

Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal management, fire

Get a quote

Research and optimization of thermal design of a container energy

The thermal performance of the battery module of a container energy storage system is analyzed based on the computational fluid dynamics simulation technology. The air distribution

Get a quote

fenrg-2022-846741 1..15

The earliest application of prefabricated cabin type energy storage in power grids is originated in Europe and North America, where the energy storage container (ESC) technology was used

Get a quote

Container Energy Storage System: All You Need to

Container energy storage, also commonly referred to as containerized energy storage or container battery storage, is an innovative

Get a quote

5 FAQs about [Container energy storage thermal management design]

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

Can CFD simulation be used in containerized energy storage battery system?

Therefore, we analyzed the airflow organization and battery surface temperature distribution of a 1540 kWh containerized energy storage battery system using CFD simulation technology. Initially, we validated the feasibility of the simulation method by comparing experimental results with numerical ones.

What is a containerized storage battery compartment?

The containerized storage battery compartment is separated by a bulkhead to form two small battery compartments with a completely symmetrical arrangement. The air-cooling principle inside the two battery compartments is exactly the same.

What turbulence model is used to simulate data centre thermal management system?

Zhang et al. used a standard k-ε turbulence model to simulate the data centre thermal management system and obtain better results. Xie et al. used a standard k-ε turbulence model to simulate the electric vehicle battery thermal management system. The calculated results are in high agreement with the experimental results.

Which column reduces the surface temperature of a battery pack?

Columns E and F have the most obvious reduction in the surface temperature of the battery pack. In contrast, the uniformity of the surface temperature of the battery packs in columns E and F was improved, and the phenomenon of the excessive surface temperature of battery packs E-6, E-7, and F-7 was improved.

Guess what you want to know

-

Energy Storage Container Energy Management System

Energy Storage Container Energy Management System

-

Japanese container photovoltaic energy storage design

Japanese container photovoltaic energy storage design

-

Overall design of energy storage container

Overall design of energy storage container

-

Design of container distributed energy storage station

Design of container distributed energy storage station

-

Container energy storage structure design

Container energy storage structure design

-

Energy Storage Container Design and Development Process

Energy Storage Container Design and Development Process

-

Container Energy Storage Project Design

Container Energy Storage Project Design

-

Design of energy storage system for solar thermal power station

Design of energy storage system for solar thermal power station

-

Bhutan Energy Storage Container Park Design

Bhutan Energy Storage Container Park Design

-

Ranking of Energy Storage Cabinet Container Manufacturers

Ranking of Energy Storage Cabinet Container Manufacturers

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.