Harmonics in Photovoltaic Inverters & Mitigation Techniques

The reference signal magnitude and frequency determine the amplitude and the frequency of the output voltage. The frequency of the carrier waveform is called the modulation frequency. To

Get a quote

Low vs High frequency inverters | DIY Solar Power Forum

If you intend to run high inductive loads such as motors found on AC watermakers, a low frequency inverter will be more reliable. If you just want to run resistive loads like water

Get a quote

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get a quote

The difference between high frequency inverter and

High frequency inverters typically operate at frequencies above 20 kHz, while low frequency inverters operate at frequencies below 2 kHz.

Get a quote

Power Frequency Inverter vs High-Frequency Inverter

High-frequency inverters and power-frequency inverters are the two common types of inverters. Each has its own different characteristics and applications, so which one is

Get a quote

How to Distinguish High Frequency Inverter and Low Frequency Inverter

The main difference between high frequency inverter and low frequency inverters is the frequency of the AC power produced. High frequency inverters produce AC power of a higher frequency

Get a quote

What Is A Square Wave Inverter? | Definition, How It

A Square Wave Inverter is a type of power inverter that converts DC (Direct Current) power into AC (Alternating Current) power with a square

Get a quote

The difference between high frequency inverter and low

High frequency inverters typically operate at frequencies above 20 kHz, while low frequency inverters operate at frequencies below 2 kHz. Another significant difference

Get a quote

Which is Better Low Frequency or High-frequency Inverter?

Low frequency inverters are simpler, more robust and easier to control. High frequency inverters enable miniaturization, fast response, efficiency and ultra-quiet operation. The choice depends

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

The difference between a high and low frequency inverter

Image Source: unsplash Understanding the difference between a high and low frequency inverter is crucial for selecting the right device for your needs. A high frequency inverter operates at

Get a quote

A Guide to Solar Inverters: How They Work & How to

Learn what a solar inverter is, how it works, how different types stack up, and how to choose which kind of inverter for your solar project.

Get a quote

A Closer Look at Inverter Generators

In an inverter generator, the core uses multiple coils and multiple magnets. Each full rotation of the engine produces more than 300 three phase ac sine waves at fre-quencies up to 20 kHz,

Get a quote

Understanding inverter frequency – effects and adjustments

Electrical appliance noise: Low switching frequency will cause the inverter to produce large harmonics when outputting AC power. These harmonics will be transmitted to

Get a quote

Inverter-based microgrids: Small-signal modelling and testing

The small-signal state-space model of an individual inverter is constructed on a synchro-nous reference frame whose rotation frequency is set by the power controller of that inverter.

Get a quote

16 Best Inverter Brands in Nigeria 2025

Inverters are becoming common[place in Nigeria, signaling a renewable energy transition. Here are the best inverter brands in Nigeria to be a part.

Get a quote

What Are The Types Of Inverters And How They Work

Discover what inverters are, the types of inverters, and how they work. Explore pure sine wave, modified sine wave, square wave, and hybrid inverters, their functions, and

Get a quote

How to Distinguish High Frequency Inverter and Low Frequency

The main difference between high frequency inverter and low frequency inverters is the frequency of the AC power produced. High frequency inverters produce AC power of a higher frequency

Get a quote

Which is Better Low Frequency or High-frequency

Low frequency inverters are simpler, more robust and easier to control. High frequency inverters enable miniaturization, fast response, efficiency and ultra

Get a quote

High-Frequency Inverter Advanced Digital Modulation Strategy

Wide bandgap semiconductor devices enable inverters with higher switching and output frequencies. This poses more challenges to obtain high-quality output waveform and control

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

Regarding small—to medium-sized inverters, the high-frequency inverter is the market-dominating choice due to its high efficiency, compact size, and ability to deliver stable power.

Get a quote

A bidirectional, sinusoidal, high-frequency inverter design

In many applications it is important for an inverter to be of relatively small size and lightweight. This can be achieved by using a high-frequency (HF) link inverter topology.

Get a quote

Keeping the noise down: Converter and inverter

Motor drives are a good example where the inverter typically produces three-phase AC outputs with variable frequency and amplitude for

Get a quote

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get a quote

High Frequency Inverter vs low Frequency Inverter

Instead, I''ll focus on the fundamental differences between low-frequency inverters and high-frequency inverters. This distinction is crucial, and I believe it''s the best place to start our

Get a quote

Guess what you want to know

-

Small high frequency inverter

Small high frequency inverter

-

High frequency inverter produces 1200v

High frequency inverter produces 1200v

-

High frequency inverter to 50hz

High frequency inverter to 50hz

-

Turkmenistan high frequency inverter price

Turkmenistan high frequency inverter price

-

Azerbaijan high frequency inverter manufacturer

Azerbaijan high frequency inverter manufacturer

-

High frequency inverter to industrial frequency

High frequency inverter to industrial frequency

-

Photovoltaic inverter high frequency tolerance

Photovoltaic inverter high frequency tolerance

-

High frequency pure sine wave inverter 12V to 48V

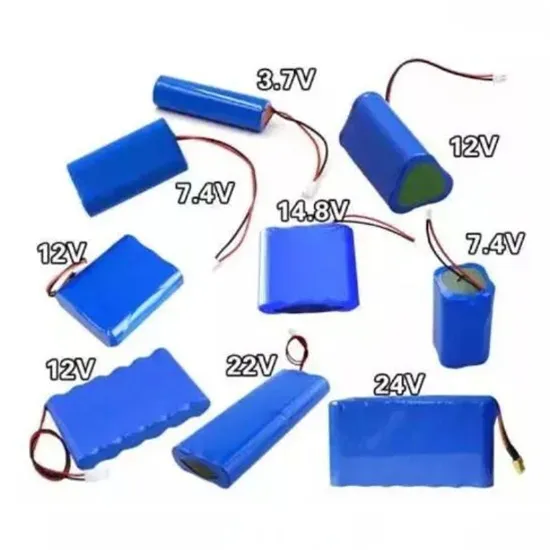

High frequency pure sine wave inverter 12V to 48V

-

Cambodia high frequency power inverter

Cambodia high frequency power inverter

-

Iran High Frequency Inverter Device Factory

Iran High Frequency Inverter Device Factory

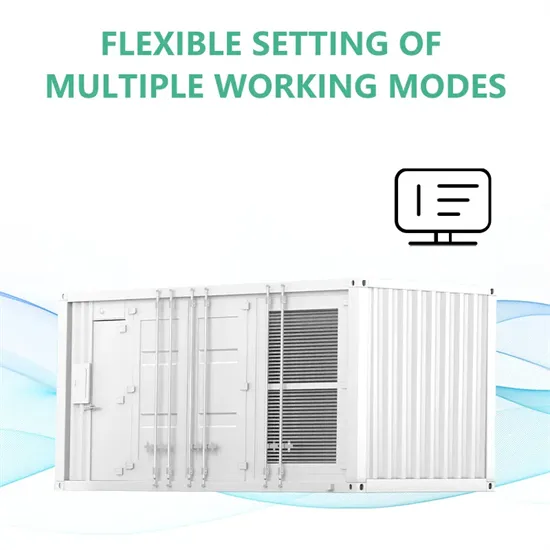

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.