High and intermediate temperature sodium–sulfur batteries for

Combining these two abundant elements as raw materials in an energy storage context leads to the sodium–sulfur battery (NaS). This review focuses solely on the progress, prospects and

Get a quote

BASF Stationary Energy Storage GmbH

BASF and NGK release advanced type of sodium-sulfur batteries (NAS Battery) NAS MODEL L24 Ludwigshafen, Germany, and Nagoya, Japan, June 10th, 2024 – BASF Stationary Energy

Get a quote

High and intermediate temperature sodium–sulfur

Combining these two abundant elements as raw materials in an energy storage context leads to the sodium–sulfur battery (NaS). This review focuses solely

Get a quote

Research on sodium sulfur battery for energy storage

Sodium sulfur battery is one of the most promising candidates for energy storage applications. This paper describes the basic features of sodium sulfur battery and summarizes

Get a quote

Sub-zero and room-temperature sodium–sulfur battery cell

The sodium-sulfur battery holds great promise as a technology that is based on inexpensive, abundant materials and that offers 1230 Wh kg−1 theoretical energy density that

Get a quote

Conversion mechanism of sulfur in room-temperature sodium

A complete reaction mechanism is proposed to explain the sulfur conversion mechanism in room-temperature sodium-sulfur battery with carbonate-based electrolyte.

Get a quote

Sodium-Sulfur (NaS) Battery

A sodium-sulfur (NaS) battery is a high-capacity, high-temperature energy storage system that stores energy using molten sodium and sulfur as active materials. These batteries

Get a quote

Sodium–sulfur battery

A sodium–sulfur (NaS) battery is a type of molten-salt battery that uses liquid sodium and liquid sulfur electrodes. [1][2] This type of battery has a similar energy density to lithium-ion batteries,

Get a quote

Sodium Sulfur Battery – Zhang''s Research Group

One advantage of a sodium sulfur battery is that it is a mature system with established experience and presence on the market. Since their container is entirely sealed

Get a quote

Handbook on Battery Energy Storage System

The Na–S battery or liquid metal battery is a type of molten metal battery constructed from sodium and sulfur. It exhibits a high energy density, high eficiency of charge and discharge

Get a quote

Sodium-sulfur battery energy storage station technology

Providing at least six hours of energy storage, a 1.5MW NAS battery at Swanbank would be one of the first in Queensland and the largest grid-connected sodium sulphur battery in Australia.

Get a quote

Bifunctional Electrolyte Additive in Room-Temperature

Room-temperature sodium–sulfur (RT Na–S) batteries have been restricted by difficulties on both electrodes: the utilization of active sulfur still

Get a quote

A Critical Review on Room-Temperature Sodium-Sulfur Batteries:

A critical review on remaining challenges and promising solutions for the practical applications of room-temperature sodium-sulfur (RT-Na/S) batteries is presented.

Get a quote

Lead batteries for utility energy storage: A review

Sodium and sulfur react on discharge to form sodium polysul de. The energy fi density is substantially higher than lead–acid batteries and they have a long cycle life.

Get a quote

Sodium Sulfur Battery

What is sodium sulfur used for? Like all other types of batteries, this type of battery also has a lot of uses and requirements for its productions. As this battery provides a cheaper

Get a quote

Sodium-Sulfur (NAS )B

Principle of Sodium Sulfur Battery Sodium Sulfur Battery is a high temperature battery which the operational temperature is 300-360 degree Celsius (572- 680 °F) Full discharge (SOC 100% to

Get a quote

A stable room-temperature sodium–sulfur battery

Here we report a room-temperature sodium–sulfur battery that uses a microporous carbon–sulfur composite cathode, and a liquid carbonate electrolyte containing the ionic liquid

Get a quote

Sodium–sulfur battery

The sodium is separated by a beta-alumina solid electrolyte (BASE) cylinder from the container of molten sulfur, which is fabricated from an inert metal serving as the cathode.

Get a quote

Sodium Sulfur Battery

The sodium–sulfur battery is formed by combining the liquid states of the negative sodium and positive sulfur electrodes. Both electrode components are in a liquid state.

Get a quote

Revealing the Hidden Polysulfides in Solid-State Na–S Batteries:

Beyond elucidating the full Na–S reaction pathway, this work emphasizes the critical role of pressure as a thermodynamic variable in exploring reaction mechanisms while

Get a quote

Sodium-Sulphur (NaS) Battery

While most of the installed base of NaS batteries is in Japan and in the USA, the first European projects have been installed in Reunion Island (France), Germa-ny, and the UK.

Get a quote

Lead batteries for utility energy storage: A review

Sodium and sulfur react on discharge to form sodium polysulfide. The energy density is substantially higher than lead–acid batteries and they have a long cycle life.

Get a quote

Conversion mechanism of sulfur in room-temperature sodium-sulfur

A complete reaction mechanism is proposed to explain the sulfur conversion mechanism in room-temperature sodium-sulfur battery with carbonate-based electrolyte.

Get a quote

Sodium Sulfur Battery

The sodium-sulfur battery (Na–S) combines a negative electrode of molten sodium, liquid sulfur at the positive electrode, and β-alumina, a sodium-ion conductor, as the electrolyte to produce 2

Get a quote

A Critical Review on Room-Temperature Sodium

A critical review on remaining challenges and promising solutions for the practical applications of room-temperature sodium-sulfur (RT-Na/S)

Get a quote

Guess what you want to know

-

Household battery cabinet container base station

Household battery cabinet container base station

-

Silicon negative electrode battery container base station

Silicon negative electrode battery container base station

-

Battery high temperature aging container base station

Battery high temperature aging container base station

-

Lead-acid battery manufacturing ESS power base station container

Lead-acid battery manufacturing ESS power base station container

-

Battery component cost container base station

Battery component cost container base station

-

Battery station cabinet container base station

Battery station cabinet container base station

-

Battery assembly set container base station

Battery assembly set container base station

-

New Energy Battery Communication Power Supply Container Base Station

New Energy Battery Communication Power Supply Container Base Station

-

Niue battery replacement site container communication base station

Niue battery replacement site container communication base station

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

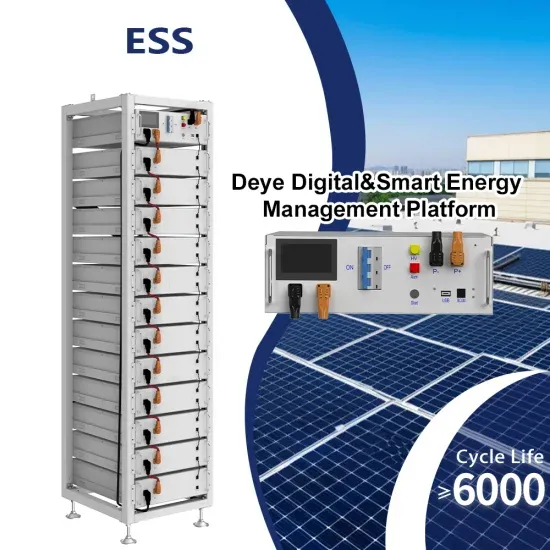

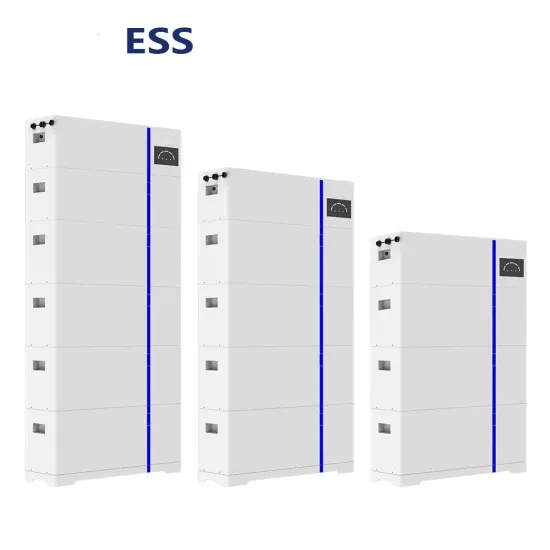

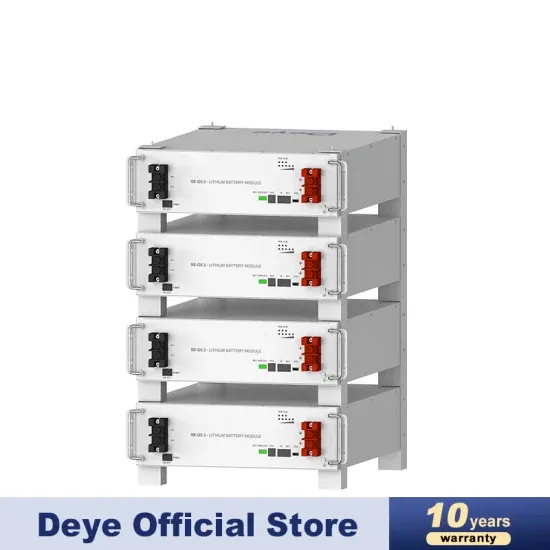

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.