How to Troubleshoot and Fix Common Inverter Problems

Check the output voltage and frequency. The output voltage and frequency of the inverter should match the requirements of the load. If the output voltage or frequency is incorrect, the load

Get a quote

Understanding inverter frequency – effects and

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical

Get a quote

32 Common Faults in Inverters and Their Solutions

Check the Battery: Ensure that the battery is fully charged. If the battery voltage is too low, the inverter may not turn on. Use a multimeter to measure the voltage. If it''s below the

Get a quote

Effects of Incorrect Maximum Output Voltage in a Frequency Inverter

Learn about the direct and indirect effects of setting an incorrect maximum output voltage in a frequency inverter on the connected motor and the overall drive system.

Get a quote

These 32 Common Inverter Faults, Have You

Check if the input high voltage power supply exceeds the allowed maximum value (if the supply voltage is too high, adjust the transformer tap to 105%).If

Get a quote

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible

Get a quote

Three Common Faults in PV Inverters and Their

PV Module Issues: Shadowing, excessive dust accumulation, or damaged cells in the modules can lead to unstable or abnormally low output voltage.Loose or

Get a quote

[SOLVED]

So if this DC bus voltage is too low, you will never get 230Vac output voltage. "Modified sine wave" inverters use similar approach, however the full bridge is switched with

Get a quote

Power Inverter Troubleshooting – Common Problems

Check your inverter''s specifications or manual to determine if parallel operation is supported and follow the manufacturer''s instructions for

Get a quote

800VA Pure Sine Wave Inverter''s Reference Design

The first step is the conversion of the low voltage DC power to a high voltage DC source, and the second step is the conversion of the high DC source to an AC waveform using pulse width

Get a quote

what does AC Voltage High mean and what should one do?

Enphase Microinverters, like all utility-interactive inverters, sense voltage and frequency from the AC grid and cease exporting power when voltage or frequency from the

Get a quote

High frequency verses low frequency inverters

What is the difference between high, or low frequency inverters the pros and cons? I have seen a few posts someone said low was better for high surge load like AC units,

Get a quote

Power Inverter Troubleshooting – Common Problems and How to

Check your inverter''s specifications or manual to determine if parallel operation is supported and follow the manufacturer''s instructions for proper setup and wiring.

Get a quote

High-Frequency Inverter: How They Work and Why

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above 20

Get a quote

Troubleshooting Inverter Problems: A Step-by-Step Guide

Check the Battery: Ensure that the battery is fully charged. If the battery voltage is too low, the inverter may not turn on. Use a multimeter to measure the voltage. If it''s below the

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

This can be caused by a missing supply voltage phase from a blown fuse or faulty isolator or contactor or internal rectifier bridge fault or simply low mains voltage.

Get a quote

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get a quote

Low Frequency Vs. High Frequency Inverters

Aims uses low-frequency inverters, while most Growatt inverters are high-frequency, with some exceptions. If you''re unsure whether an inverter is low or high frequency, check the weight.

Get a quote

How to Troubleshoot and Fix Common Inverter Problems

Check the output voltage and frequency. The output voltage and frequency of the inverter should match the requirements of the load. If the output voltage or

Get a quote

Effects of Incorrect Maximum Output Voltage in a Frequency

Learn about the direct and indirect effects of setting an incorrect maximum output voltage in a frequency inverter on the connected motor and the overall drive system.

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always working efficiently!

Get a quote

Common Solar Power Inverter Problems and How to Balance Them

Overvoltage or Under voltage: Inverters can sometimes shut down if the voltage is too high or too low. Ensure the input voltage from the solar panels is within the acceptable

Get a quote

Power Inverter Troubleshooting – Common Problems and How to

Compare the measured voltage to the inverter''s rated output voltage If the voltage is low or absent, the inverter may be faulty and require repair or replacement

Get a quote

Do Inverters Turn Off When Voltage is too low?

Most inverters have a low voltage cut off, i.e., if batteries drop below X, inverter shuts down. Most inverters will not operate if they can''t provide rated current, voltage and

Get a quote

AC input (gen) problem

Because this is NOT an inverter generator, the engine speed is tied to output frequency. Thus the output frequency drops until a load is applied and the generator speeds

Get a quote

How to change the solar panel voltage if it is too high

In situations where the voltage produced by solar panels exceeds the desired or required levels, there are effective strategies to manage the

Get a quote

Top 10 Low Frequency Power Inverters Reviewed

Its pure sine wave output, high efficiency, and remote monitoring capabilities make it a standout choice. Renogy 2000W Pure Sine Wave Inverter For off-grid solar systems, the Renogy

Get a quote

6 FAQs about [The inverter output high voltage frequency is too low]

How to troubleshoot an inverter?

Once you have identified the problem, you can begin troubleshooting it. Here are some steps to follow: Check the input voltage. The input voltage to the inverter should be within the specified range. If the input voltage is too low or too high, the inverter may not function properly. Check the output voltage and frequency.

What if the frequency inverter voltage is too high?

When the system voltage is too high, the frequency inverter may not be able to stop at a numerical point in order to avoid triggering the DC bus over-voltage protection for its own protection. In such cases, it is recommended to connect the transformer taps to 105%.

Why is my inverter low voltage?

Another possible cause could be an inadequate power source or improper electrical connections. Faulty wiring can also result in voltage fluctuations. If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health.

What is inverter low voltage?

Now that we know what inverter low voltage is, let's explore some common causes behind it. One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible cause could be an inadequate power source or improper electrical connections.

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

What are the most common faults on inverters?

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage Overvoltage This is caused by a high intermediate circuit DC voltage. This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage.

Guess what you want to know

-

Is the inverter voltage output high or low

Is the inverter voltage output high or low

-

Low voltage inverter high voltage grid connection

Low voltage inverter high voltage grid connection

-

Single-phase high and low voltage inverter

Single-phase high and low voltage inverter

-

High frequency inverter voltage can reach

High frequency inverter voltage can reach

-

Can the inverter convert low voltage into high voltage

Can the inverter convert low voltage into high voltage

-

Inverter voltage high and low

Inverter voltage high and low

-

Inverter high voltage side and low voltage side

Inverter high voltage side and low voltage side

-

The higher the voltage the higher the high frequency inverter

The higher the voltage the higher the high frequency inverter

-

Does the inverter consume power at low frequency or high frequency

Does the inverter consume power at low frequency or high frequency

-

Advantages and disadvantages of dual silicon high frequency inverter

Advantages and disadvantages of dual silicon high frequency inverter

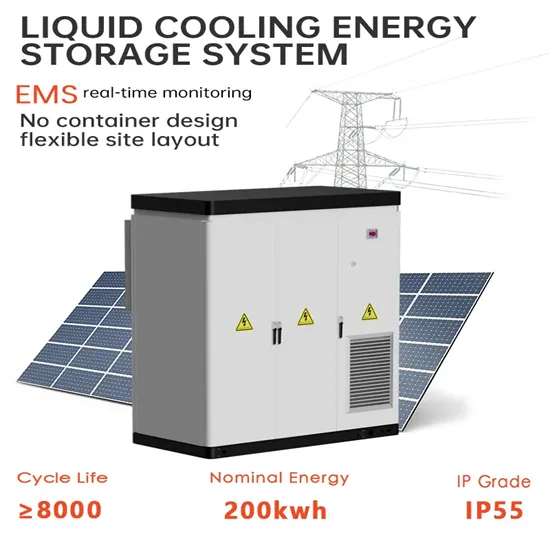

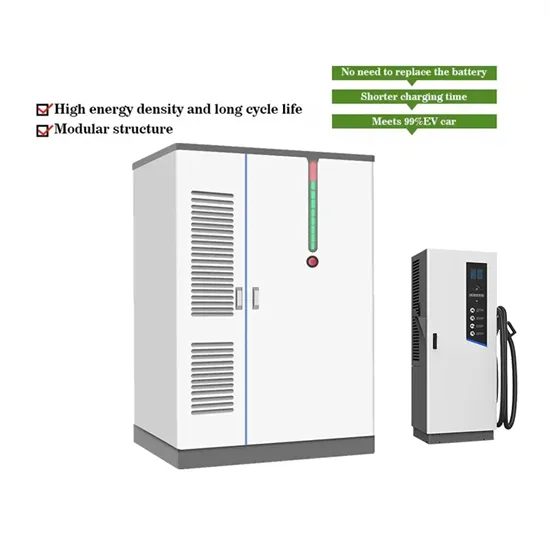

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.