Enhancing the vanadium redox flow battery efficiency by

Results from the simulation show that the configuration of the cell (case 7) has the best battery efficiency under different ranges of flow rates, while the worse one is (case 4) under the same

Get a quote

Performance enhancement of vanadium redox flow battery by

Two different commercial carbon felt electrodes for vanadium redox flow battery, based on polyacrylonitrile and rayon, are tested and compared in order to evaluate the effect

Get a quote

Thermal modelling of battery configuration and self-discharge reactions

Mathematical modelling of the all-vanadium redox flow battery can assist in analysing the battery performance under different operating and climatic conditions for the

Get a quote

Investigation of Kinetic and Mass Transport Behaviors of V2+ and

Investigation of Kinetic and Mass Transport Behaviors of V2+ and V3+ Ions Using Symmetric Vanadium Redox Flow Battery Configuration, Sun, Pengfei, Suzuki, Takahiro,

Get a quote

Introducing ENDURIUM: Transforming Grid-Scale

Invinity today unveils its fourth-generation vanadium flow battery, optimising our proven product platform for large-scale energy storage.

Get a quote

Design and Development of Flow Fields with Multiple Inlets or

With the support of a 3D computational fluid dynamic model, this work presents two novel flow field geometries that are designed to tune the direction of the pressure

Get a quote

How Vanadium Flow Batteries Work

In contrast to lithium-ion batteries which store electrochemical energy in solid forms of lithium, flow batteries use a liquid electrolyte instead, stored in large tanks. In VFBs, this electrolyte is

Get a quote

Species Uptake and Mass Transport in Membranes for Vanadium Redox Flow

In this contribution, we provide a synthesis of results to date describing uptake and mass transport of water, vanadium species and protons in Nafion membranes for use as

Get a quote

Energy Storage Beyond Lithium / Invinity Energy

See what makes Invinity the world''s leading manufacturer of utility-grade energy storage - safe, economical & proven vanadium flow batteries.

Get a quote

Modeling the pressure drop in vanadium redox flow batteries

The effect of flow rate, viscosity, porosity, electrode thickness, effect of channel height, effect of channel width and effect of number of channels on the pressure drop in a

Get a quote

Modeling and Optimization of Vanadium Flow Batteries

In this paper, a vanadium flow battery dynamic model incorporating the variable vanadium ion permeabilities and cell resistance is proposed and a subsequent in-depth

Get a quote

Vanadium Redox Flow Batteries: Electrochemical

This chapter covers the basic principles of vanadium redox flow batteries, component technologies, flow configurations, operation strategies,

Get a quote

Role of Vanadium Redox Flow Batteries in the Integration of Multi

This chapter is devoted to presenting vanadium redox flow battery technology and its integration in multi-energy systems. As starting point, the concept, characteristics and

Get a quote

Long term performance evaluation of a commercial vanadium flow battery

This demonstrates the advantage that the flow batteries employing vanadium chemistry have a very long cycle life. Furthermore, electrochemical impedance spectroscopy

Get a quote

How Vanadium Flow Batteries Work

In contrast to lithium-ion batteries which store electrochemical energy in solid forms of lithium, flow batteries use a liquid electrolyte instead, stored in large

Get a quote

Preparation of vanadium flow battery electrolytes: in-depth

The preparation technology for vanadium flow battery (VRFB) electrolytes directly impacts their energy storage performance and economic viability. This review analyzes

Get a quote

Advanced Materials for Vanadium Redox Flow Batteries: Major

It provides a comprehensive assessment of the performance, environmental sustainability, and economic feasibility of these components, aiming to offer strategic guidance

Get a quote

Vanadium Flow Battery: How It Works and Its Role in Energy

Vanadium flow batteries consist of two tanks containing vanadium electrolyte, a pump system to circulate the electrolyte, and a fuel cell stack where the electrochemical

Get a quote

Modeling the Velocity Profiles in Vanadium Redox Flow Batteries

The model considers the effect of electrolyte flow rate, viscosity, channel height, channel width, electrode porosity and electrode thickness on the electrolyte velocity profile

Get a quote

Sumitomo Electric Develops Advanced Vanadium Redox Flow Battery

Sumitomo Electric is pleased to introduce its advanced vanadium redox flow battery (VRFB) at Energy Storage North America (ESNA), held at the San Diego Convention

Get a quote

Flow field design and optimization of high power density vanadium flow

One of the effective strategies for developing high power density stacks is to enhance the mass transport by performing flow field design. Based on the maldistribution

Get a quote

Flow battery electrolyte configuration

A battery''''s performance and efficiency are greatly influenced by the electrolyte flow rate. By increasing the flow rate, the pump power loss will increase, leading to a decrease in system

Get a quote

Vanadium redox flow batteries to reach greenhouse gas

This study determines the minimum cost configuration of vanadium redox flow batteries (VRFB), wind turbines, and natural gas reciprocating engines in an off-grid model. A

Get a quote

Vanadium Redox Flow Batteries-Pressure Drop Studies in Serpentine Flow

Request PDF | Vanadium Redox Flow Batteries-Pressure Drop Studies in Serpentine Flow Field Configuration | A battery''s performance and efficiency are greatly

Get a quote

Thermal modelling of battery configuration and self-discharge

Mathematical modelling of the all-vanadium redox flow battery can assist in analysing the battery performance under different operating and climatic conditions for the

Get a quote

Guess what you want to know

-

Vanadium redox flow battery equipment manufacturing

Vanadium redox flow battery equipment manufacturing

-

Smart vanadium flow battery

Smart vanadium flow battery

-

Huawei vanadium flow battery energy storage industry

Huawei vanadium flow battery energy storage industry

-

Vanadium titanium all-vanadium liquid flow energy storage battery

Vanadium titanium all-vanadium liquid flow energy storage battery

-

Vanadium flow battery industry

Vanadium flow battery industry

-

Vanadium flow battery in western Denmark mining

Vanadium flow battery in western Denmark mining

-

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

Dominica s new vanadium titanium GW-grade all-vanadium liquid flow energy storage battery

-

Vanadium flow battery reaction

Vanadium flow battery reaction

-

Vanadium Flow Battery Trend

Vanadium Flow Battery Trend

-

Vanadium flow battery energy storage trends

Vanadium flow battery energy storage trends

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

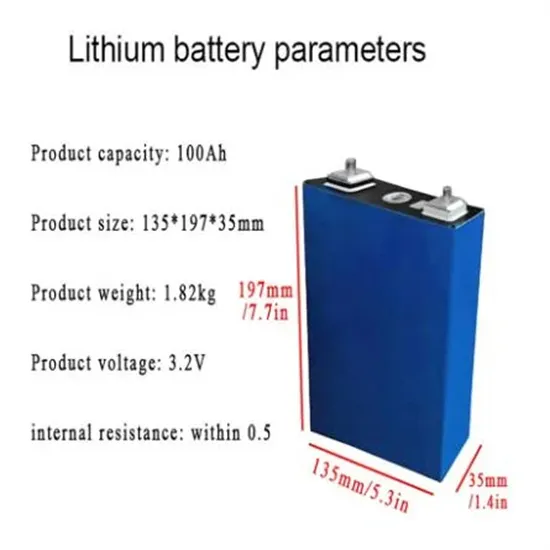

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.