A review of flywheel energy storage systems: state of the art and

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Get a quote

Technology: Flywheel Energy Storage

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm.

Get a quote

The High-speed Flywheel Energy Storage System

2. Electromechanical energy storage using a flywheel A flywheel energy storage system converts electrical energy supplied from DC or three-phase AC power source into kinetic energy of a

Get a quote

What Is a Flywheel? | Functions of Flywheel | Types of

A flywheel is a computerized apparatus that operates the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to

Get a quote

The Flywheel Energy Storage System: A Conceptual Study,

Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and reliability of the

Get a quote

Structure and components of flywheel energy storage system

Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system (FESS). Although these losses are typically small in a

Get a quote

Flywheel Energy Storage

Flywheel energy storage or FES is a storage device which stores/maintains kinetic energy through a rotor/flywheel rotation. Flywheel technology has two approaches, i.e. kinetic energy

Get a quote

Flywheel Energy Storage (FES) Systems

Energy storage: As the flywheel spins, it stores kinetic energy. The energy can be stored as long as the flywheel continues to spin. The flywheel is

Get a quote

How does flywheel energy storage work?

The ability to quickly discharge energy makes flywheel energy storage systems ideal for applications that require rapid response times, such as providing short - term power

Get a quote

What are the functions of flywheel energy storage?

At its core, a flywheel energy storage system operates by storing mechanical energy in a rapidly spinning mass. This mechanism enables the

Get a quote

A review of flywheel energy storage systems: state of the art

ESSs store intermittent renewable energy to create reliable micro-grids that run continuously and efficiently distribute electricity by balancing the supply and the load [1].

Get a quote

E-13934 Cover

The main components of the flywheel energy storage system are the composite rotor, motor/generator, magnetic bearings, touchdown bearings, and vacuum housing. The flywheel

Get a quote

What are the functions of flywheel energy storage? | NenPower

At its core, a flywheel energy storage system operates by storing mechanical energy in a rapidly spinning mass. This mechanism enables the system to efficiently absorb

Get a quote

Flywheel | Function, types, Advantages, Application

Flywheel | Function, types, Advantages, Application A flywheel is a heavy rotating body which acts as a reservoir of energy. It acts as a bank of energy

Get a quote

What is Flywheel Energy Storage? How Does It Provide Short

At its core, flywheel energy storage involves the use of a rotating mass, known as a rotor or flywheel, to store kinetic energy. This energy is accumulated by accelerating the

Get a quote

Flywheel Energy Storage (FES) Systems

Energy storage: As the flywheel spins, it stores kinetic energy. The energy can be stored as long as the flywheel continues to spin. The flywheel is often located in a vacuum

Get a quote

Analysis of Standby Losses and Charging Cycles in

Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system

Get a quote

Unlocking the Power of the Flywheel: Unraveling its Purpose and

The flywheel, a seemingly simple yet intricately designed mechanical component, has been a cornerstone of various industrial and technological applications for centuries. From

Get a quote

A of the Application and Development of Energy Storage

Abstract: High power density, high efficiency and low loss are the characteristics of flywheel energy storage, which has broad application prospects in the field of rail transit. This paper

Get a quote

A cross-entropy-based synergy method for capacity

Energy storage systems, coupled with power sources, are applied as an important means of frequency regulation support for large-scale grid connection of new energy. Flywheel

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

What Is a Flywheel Energy Storage System? A flywheel energy storage system is a mechanical device used to store energy through rotational motion. When excess electricity is available, it

Get a quote

Flywheel Energy Storage

This results in the storage of kinetic energy. When energy is required, the motor functions as a generator, because the flywheel transfers rotational energy to it.

Get a quote

Flywheel Energy Storage System: What Is It and How

What Is a Flywheel Energy Storage System? A flywheel energy storage system is a mechanical device used to store energy through rotational motion. When

Get a quote

Flywheel Energy Storage | Working & Applications

A flywheel is an inertial energy storage device. It absorbs mechanical energy and serves as a reservoir, storing energy during the period

Get a quote

Guess what you want to know

-

When the flywheel energy storage is discharged the flywheel acts as

When the flywheel energy storage is discharged the flywheel acts as

-

Investment and construction of flywheel energy storage plant

Investment and construction of flywheel energy storage plant

-

Australian flywheel energy storage ESS system

Australian flywheel energy storage ESS system

-

Flywheel energy storage 10 000 revolutions

Flywheel energy storage 10 000 revolutions

-

Poland 5G flywheel energy storage cost price

Poland 5G flywheel energy storage cost price

-

Composition of flywheel energy storage device

Composition of flywheel energy storage device

-

Flywheel energy storage cooling system

Flywheel energy storage cooling system

-

How to replace flywheel energy storage wind power

How to replace flywheel energy storage wind power

-

West African Flywheel Energy Storage Equipment Customization Factory

West African Flywheel Energy Storage Equipment Customization Factory

-

Flywheel energy storage distributed power generation

Flywheel energy storage distributed power generation

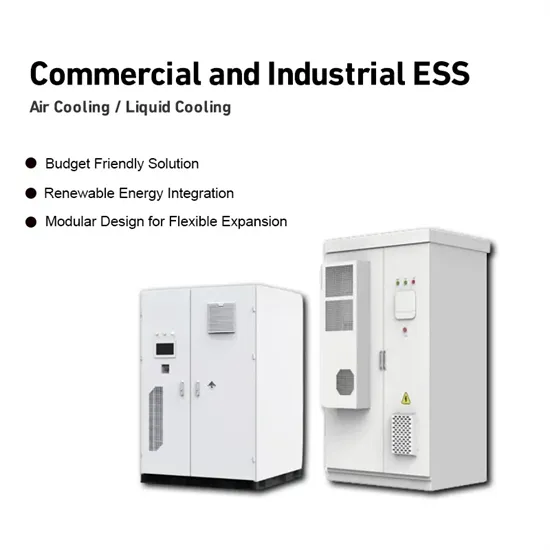

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.